OXBOTICA’S PIONEERING DEEPFAKE TECHNOLOGY BRINGS UNIVERSAL AUTONOMY WITHIN SIGHT

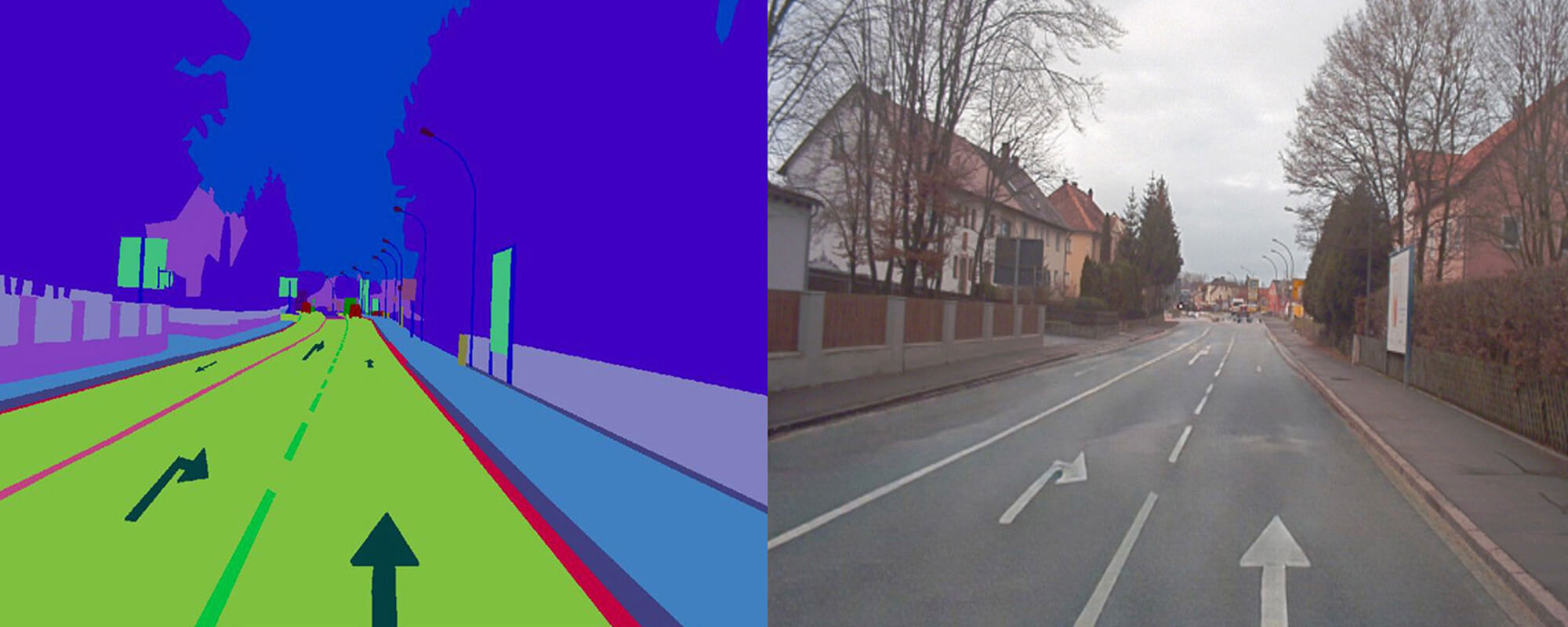

Oxbotica has developed and deployed a “deepfake” technology that is capable of generating thousands of photo-realistic images in minutes; helping to expose its autonomous vehicles to the near infinite variations of the same situation – without real-world testing of a location having ever taken place.

Deepfaking, which first shot to fame when it was used to create viral internet videos, employs deep learning artificial intelligence (AI) to generate fake photo-realistic images.

The AV software firm believes that the pioneering technology will make the vehicles of tomorrow smarter and safer, and immediately accelerate the race to autonomy.

Sophisticated deepfake algorithms allow the autonomous vehicle software firm to reproduce the same scene in poor weather or adverse conditions, and subject its vehicles to rare occurrences.

The technology is so advanced that it can reverse road signage or “class switch”, where one object (e.g. a tree) is replaced with another (e.g. a building). It can change the lighting of an image, to show a particular frame at a different time of the day or season of the year, all while ensuring shadows or reflections appear exactly as they should. It then uses these synthetic images to teach its software, producing thousands of accurately-labelled, true-to-life experiences and rehearsals which are not real but generated; even down to the rain drops on lenses.

Paul Newman, Co-Founder and CTO at Oxbotica, said: “Using deepfakes is an incredible opportunity for us to increase the speed and efficiency of safely bringing autonomy to any vehicle in any environment – a central focus of our Universal Autonomy vision. What we’re really doing here is training our AI to produce a syllabus for other AIs to learn from. It’s the equivalent of giving someone a fishing rod rather than a fish. It offers remarkable scaling opportunities.

“There is no substitute for real-world testing but the autonomous vehicle industry has become concerned with the number of miles travelled as a synonym for safety. And yet, you cannot guarantee the vehicle will confront every eventuality, you’re relying on chance encounter.

“The use of deepfakes enables us to test countless scenarios, which will not only enable us to scale our real-world testing exponentially; it’ll also be safer.”

The data is generated by an advanced teaching cycle made up of two co-evolving AIs, one is attempting to create ever more convincing fake images while the other tries to detect which are real and which have been reproduced. Oxbotica engineers have designed a feedback mechanism which sees both entities improve over time in a bid to outsmart their adversary. Over time, the detection mechanism will become unable to spot the difference, which means the deepfake AI module is ready to be used to generate data to teach other AIs.

The benefit of which is not in eliminating real experiences but rather augmenting them in a way which scales arbitrarily faster than time or human resource. At any one time, Oxbotica is able to generate the experiences of any number of vehicles in any number of settings, taking into account different lighting or weather conditions.

The technology allows Oxbotica’s world-leading autonomous software to be safely deployed at scale on any vehicle, anywhere around the globe, in any weather conditions and at any time of day.

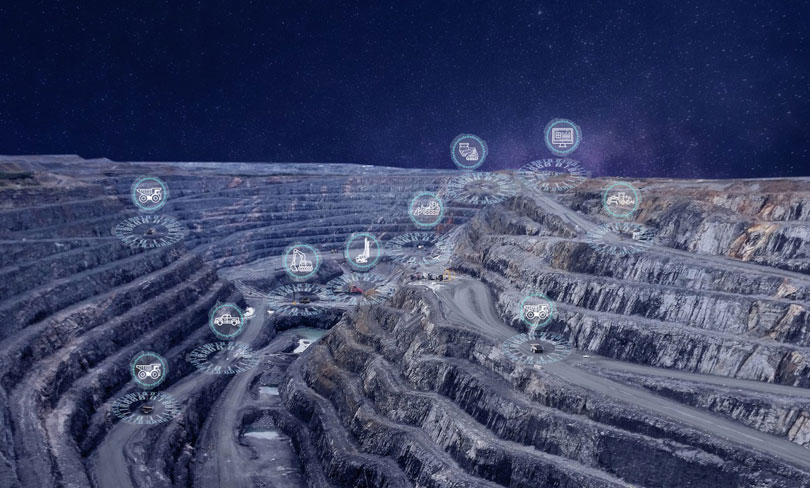

WENCO AND OXBOTICA PARTNER TO DEVELOP FIRST-EVER OPEN AUTONOMY SOLUTION FOR MINING INDUSTRY

Wenco International Mining Systems Ltd. (“Wenco”) and Oxbotica Ltd. (“Oxbotica”) have signed a Memorandum of Understanding (MOU) to develop a world-first Open Autonomy solution for mining. Initial trials are underway, and the companies are actively recruiting mining partners with appropriate testing grounds.

The industry-leading system will provide customers flexibility and efficiency in autonomous mining deployment, allowing them to operate any open standard-based vehicle and integrate it into their existing fleet. It will help meet growing demand with the number of autonomous haulage trucks around the world expected to grow by more than 300% by 20231.

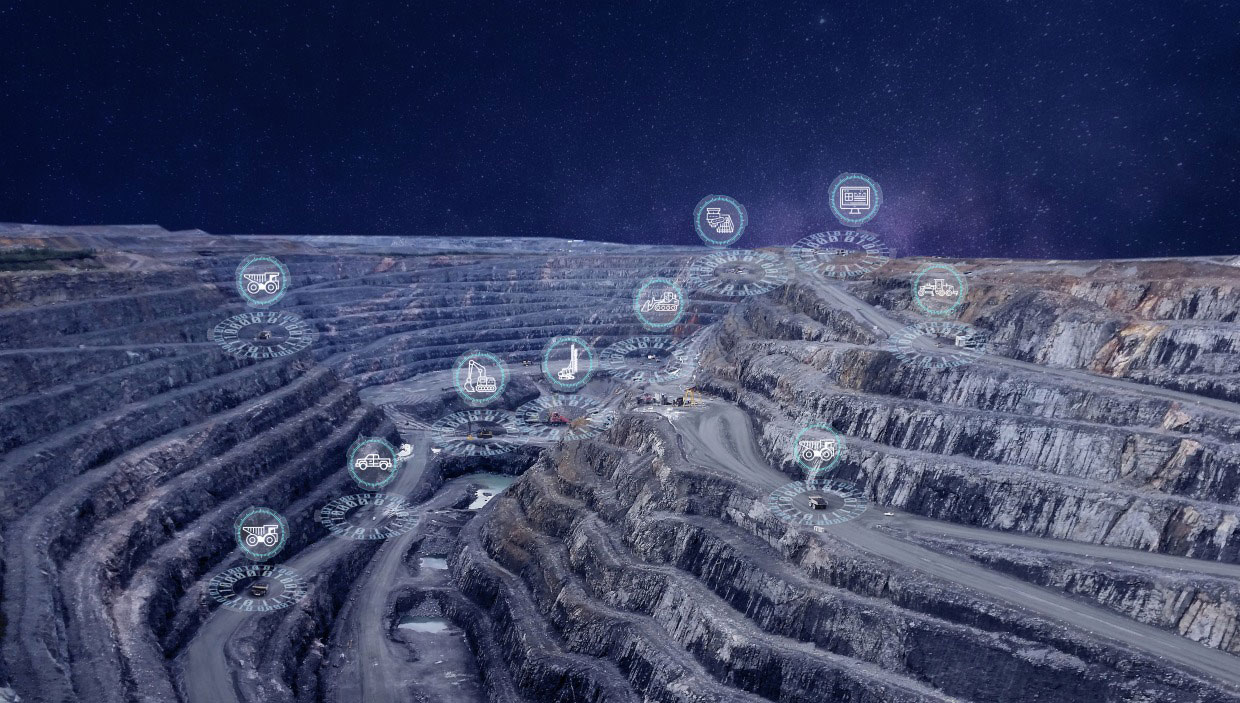

Wenco and Oxbotica both support an open and interoperable ecosystem of partners that integrate solutions alongside existing mine infrastructure. Both companies believe this provides customers with the greatest flexibility and control for integrating new solutions while reducing associated risks and costs.

This approach also notably avoids vendor lock-in and offers customers the freedom to choose preferred technologies, independent of their primary industrial systems. Furthermore, it enables highly skilled autonomy suppliers that may be new to mining to integrate with customers’ existing operations while backed by a proven expert in the industry.

A wholly owned subsidiary company of Hitachi Construction Machinery, Wenco, has 30 years’ experience in developing technology solutions that assist mining companies in maximising resource value from their operations. This latest advancement builds on the vision of Open Autonomy – first publicly announced by Wenco and its parent, Hitachi Construction Machinery, at the Canadian Institute of Mining, Metallurgy and Petroleum (CIM) Convention in Montreal in May 2019.

“We are very excited to be collaborating with Oxbotica,” says Andrew Pyne, Wenco President and CEO. “We are confident that combining Oxbotica’s proven capability in autonomy with our three decades worth of experience in interoperable fleet management systems for large mining customers enables us to create the industry’s first full-function Open Autonomy platform.

“Regardless of the strategies of other industrial autonomy vendors, Wenco and Oxbotica believe firmly in the principle of open systems and consider it the primary way to bring about our joint goals of widespread adoption of autonomous technology and safer, more productive industrial operations. Our joint platform will allow customers to choose any open standards-based vehicle and integrate it into their existing operations.”

Oxbotica was founded in 2014 out of the University of Oxford to develop an autonomy software platform that enables faster deployment of industry-specific autonomy applications. The company recognised early on the immense potential for transformation, cost savings, and safety improvements that can be achieved in the mining industry via the use of vehicle autonomy. Its mining solutions combine the best of advanced robotics, artificial intelligence and computer vision to change the way mining vehicle fleets operate.

“This collaboration with Wenco is a major milestone for Oxbotica,” says Ozgur Tohumcu, CEO of Oxbotica. “Wenco’s industry experience in mining and their vision for Open Autonomy make this partnership extremely valuable for us and provides a great synergy with our own vision of Universal Autonomy – where any vehicle, in any environment, can understand where it is, what’s around it and what it should do next.”

“The mining industry has proven to be at the forefront of deploying early generation autonomy systems because the business case has been clear for operators. However, even years after early deployments, less than two per cent of vehicles are autonomous in mines around the world. We strongly believe an Open Autonomy architecture that enables new and innovative entrants, like Oxbotica, to join and speed up autonomy adoption will be beneficial for the whole industry. Together with Wenco, we would like to accelerate the adoption of autonomy in mining, making it much easier for mine operators to deploy autonomous technologies and enjoy the benefits.”

About Open Autonomy

For a system to be classed as an open system, it must meet four key elements: be fully defined so different parties can work within the same framework, be stable, be published and be unable to be controlled by a single party.

Open Autonomy, technologies that use open standards to facilitate visibility and control of systems without direct human interaction, relies heavily on open standards, such as ANSI/ISA-95 and those advanced by the International Organisation for Standardisation (ISO). These standards are fully defined, published, and voted on by industry experts from suppliers and mining companies — ensuring an absence of bias. Wenco has worked closely with the ISO and other bodies in recent years to advance these standards in support of its open approach to industrial autonomy.