THREE WAYS RAIN RFID ENABLES SMARTER VEHICLE MANUFACTURING

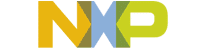

In the area of automotive manufacturing, known for its early adoption of new technology, auto makers have been some of the first to deploy Industry 4.0 techniques. They’re using cyber-physical systems to streamline operations, make assembly lines more responsive, implement preventive maintenance programs, connect geographically-distant facilities, and shorten delivery times.

RAIN RFID is a prominent part of this transition to Industry 4.0, because it lets everything – parts, components, containers, tools, and finished products – become integrated into the automated processes within the manufacturing plant and at every point in the supply chain.

Every Item Has a Traceable Identity

RAIN RFID is the commercial name for the ultra-high frequency (UHF) technology behind the EPC Global Gen2 V2 / ISO18000-6 standards. It’s a passive wireless technology, meaning it doesn’t need a battery. It can be embedded in rigid tags, paper stickers and as part of circuit boards. It can then read very accurately at a distance of several meters, without line of sight, and in bulk. RAIN RFID makes it possible to identify, locate, and engage items and has been used in supply chains for many years. Today, it connects billions of everyday items to the internet.

"RAIN RFID gives every item its own unique identity, so it can be part of track and trace systems. It also support enhanced intelligence, for dynamic interaction and secure authentication to establish full trust."

From an automotive standpoint, using RAIN RFID for item-level digitization delivers several benefits to manufacturing, including enhanced life-cycle management, increased supply-chain transparency, smarter factories, and improved customer experiences and services.

Tailored for Automotive

Vehicle manufacturing has its own particular requirements for ruggedness and reliability. To support this challenging operating environment, there are RAIN RFID tags made with special adhesives and materials that are purpose-engineered and pre-qualified to withstand the automotive-grade production and operation. RAIN RFID tags can go where barcodes and other optical codes can’t, including high-temperature paint environments, where the peak temperature can range between 190 and 230 °C.

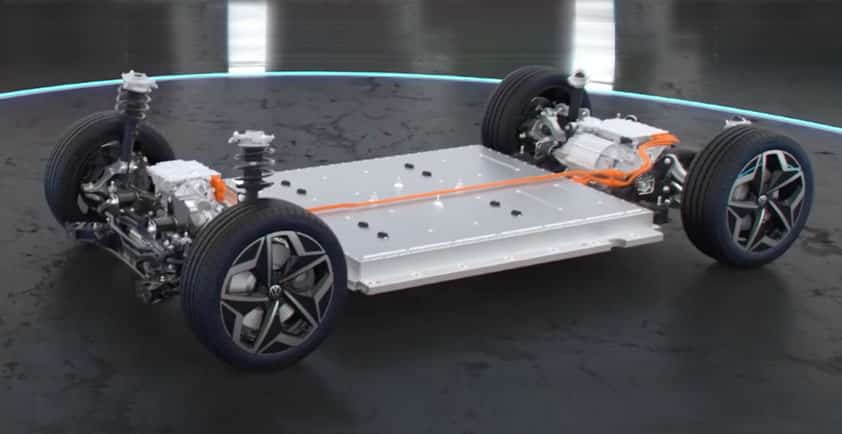

As a result, RAIN RFID can be used almost anywhere in the vehicle – inside, outside, under the hood – and with difficult-to-label automotive components, including batteries, engine blocks, fuel caps, bumpers, cables and tires.

Benefits Up and Down the Supply Chain

There are dozens of use cases, up and down the supply chain, where RAIN RFID can enhance operations. Whether it’s upstream from manufacturing, with suppliers of raw materials, components, and sub-assemblies, or downstream with third-party logistics companies and dealership, RAIN RFID can enhance transparency, streamline processes, and help increase efficiency.

1. End-to-end transparency: RAIN RFID enables full visibility, from the earliest stages of manufacturing to final vehicle delivery and beyond. Shipping and receiving supply-chain items becomes more automated, with the ability to process many items at once, so inventory control is faster, and more precise, and everyone can access real-time information about item status. Full traceability on each item makes it easier to monitor compliance with safety regulations, and simplifies recalls if there are quality deviations.

2. Better process control: RAIN RFID ensures that the right parts, components, and tools are in the right location when they’re needed, so production lines can stay up and running. There’s less downtime, because everything is on hand and because machines can self-monitor and send alerts to schedule preventive maintenance. Automated shipping notices, issued without inserting extra steps to the shipping process, keep suppliers and customers better informed without adding effort.

3. Increased efficiency: RAIN RFID allows for more automation and, as a result, makes manufacturing processes more efficient. Highly accurate bulk reads, without line of sight, can be done in an instant, making it possible to verify that every item loaded into a shipping container, stored into a bin, or loaded onto a truck, is accounted for. RAIN RFID also supports predictive maintenance, since tags can provide the data needed to ensure equipment is available as needed, so there are fewer delays caused by downed equipment and unexpected repairs.

An Innovative Example

A relatively new innovation is RAIN RFID tags for tires. The tag can withstand vulcanization, so it can be embedded inside the rubber, where it can provide identification and collect information as it proceeds through the supply chain. Once the tire is in use, on a vehicle, the tag makes it easier to integrate after-sales services, with quick reads of tire type and origin, as well as operating data such as tire pressure and distance traveled.

Just the Beginning

The examples given here are only a glimpse of what’s possible when RAIN RFID becomes part of the supply chain for vehicle manufacturing. At NXP, we’re working with companies throughout the automotive sector to use RAIN RFID as a way to enhance lifecycle management, increase supply-chain transparency, make factories smarter, and improve driver experiences.

Our UCODE family of RAIN RFID ICs includes three categories of technology and supports use cases that range from basic identification to reprogrammable memory for dynamic interactions and crypto-functionality for high-level security. Along with our partners in the RAIN RFID ecosystem, we support different aspects of operation, from tags and readers to software, including applications on readers, backend software in the enterprise, and analytics in the cloud.

Author - Mahdi Mekic, Marketing Director at NXP Semiconductors