HESAI ANNOUNCES TWO REVOLUTIONARY NEW ADAS LIDAR PRODUCTS AND COMPLETION OF ITS STATE-OF-THE-ART R&D CENTER FOR MANUFACTURING

>> Introduce the world's most advanced, highest performance ADAS lidar, Hesai AT512, boasting the industry's longest range and transformative highest ever resolution.

>> Display Hesai's new ultra-thin 25 mm ET25 lidar with super long range and ultra-fine resolution, and designed to be mounted behind the windshield.

>> Announce completion of our new 740,000 sq ft. "Maxwell" Innovation Center, combining R&D and high-volume manufacturing lines, and equipped with the world's most advanced lidar testing lab.

PALO ALTO, Calif. -- Hesai Technology, a global leader in lidar technologies for autonomous mobility systems, ADAS and industrial robotics applications, today announced a series of high-profile product releases and business developments, seeking to advance intelligent driving systems to improve the efficiency and safety of global transportation and save lives. Today's announcements illustrate the company's unmatched prowess in the areas of lidar innovation, advanced manufacturing and rapid commercialization.

The first announcement of the day is the launch of Hesai's new flagship AT512 ultra long-range ADAS lidar. The AT512 is Hesai's top-of-the-line, category killer product and represents a leapfrog advancement in lidar innovation in a trim, compact form factor, targeting automotive OEMs who demand the very best in performance, reliability and safety. The AT512 offers an industry-leading range of 300 meters at 10% reflectivity with a maximum range of over 400 meters, and an industry-record 12.3 million points per second point-rate, multiples ahead of the ADAS competitors, resulting in the highest resolution point cloud among any lidar manufacturer at 2400 x 512. The product's sleek physical design measures just 160x100x45mm while offering a 120-degree horizontal field of view and a 25.6-degree vertical field of view. The AT512 is designed to greatly enhance ADAS systems by improving the vehicle's perception capabilities by providing world class 3D environmental scans at ultra-high resolution, which greatly improves a vehicle's ability to detect objects at long range. This game-changing lidar means AT512 equipped ADAS systems will have 40% more reaction time to avoid dangerous road conditions and significantly improve transportation safety.

"The AT512 represents a tremendous breakthrough in lidar technology and provides unprecedented performance improvements in all of the key areas our customers care about such as range, resolution, thermal, power consumption and form factor," said David Li, Co-founder and CEO of Hesai. "Our core belief that intelligent manufacturing needs to be part of our R&D efforts has helped us move beyond traditional 1550 nanometer laser-based lidar to more advanced 905 nanometer technology as borne out by the superior performance, quality and reliability of our AT512."

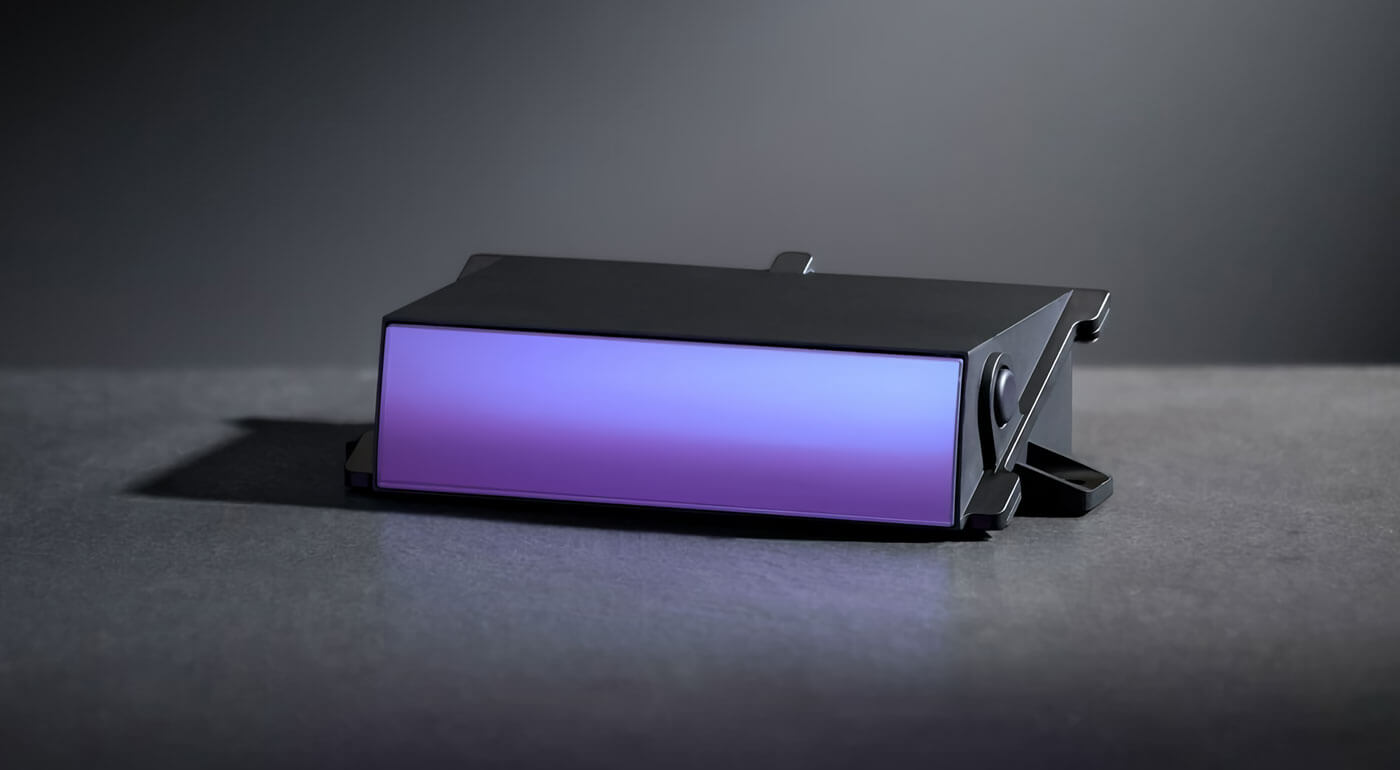

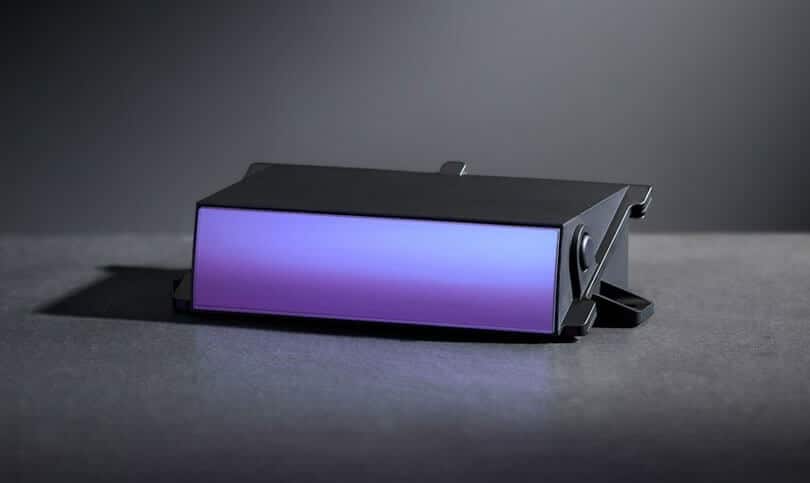

The second announcement of the day is the public reveal of the new ultra-thin ET25 ADAS lidar designed to be installed behind a vehicle's windshield which makes it much easier to integrate, helps maintain the vehicle aerodynamics and keeps the lidar clear of dirt and debris. The ET25 provides powerful performance combined with a revolutionary design that makes vehicle integration easier than ever. The ET25 provides 250 meters of range at 10% reflectivity and received a 2024 CES Innovation Award for best new product.

"The ET25 is a revolutionary product that provides an ultra-thin design without sacrificing performance," said Li. "We're already working with leading OEMs to integrate the ET25 into series production vehicles with the start of production planned for Q1 of 2025."

Continuing the wave of new business developments is the news Hesai has completed construction on a new 740,000 square foot state-of-the-art R&D center for manufacturing, named "Maxwell" after Scottish physicist James Maxwell's famous equations which form the foundation of electromagnetism, optics, electric and magnetic circuits. The new cutting-edge facility includes the world's most advanced lidar testing lab and will utilize many smart industrial robots allowing for the automation of over 100 production processes with an automation rate of 90% and a 45 second cycle time per lidar unit. The new facility uses a proprietary smart cloud manufacturing execution system (MES) capable of precisely tracking the entire production chain and allows for any problem to be traced back to the source, precisely located and promptly controlled.

"Our new Maxwell facility is not a traditional manufacturing facility but an advanced R&D center where we design and build automated lidar production lines, which can then be easily replicated across our global network of manufacturing facilities," said Li. "With Hesai's commercial engine now in full swing, we expect to drive lidar adoption forward for everyone."

Today's news comes on the heels of Hesai winning a lidar design contract with a leading global OEM for an upcoming fully electric series production program. The company also recently surpassed 300,000 accumulative units delivered including a new high of 50,000 units in the month of December alone. To date Hesai automotive lidar have been selected by 15 leading OEMs and tier-1 suppliers, covering over 50 series production models and growing.