EQUINIX CUSTOMER CASE STUDY - ENABLING IMMENSE DATA INTAKE FOR TOMORROW’S AUTOMATED VEHICLE

Global supplier of automotive software products increases upload speeds by 1000% through partnership with Equinix as its dedicated data handler and protector

Business results

> Improved speed—total upload time for 30 cars decreased from ~85 days to just 14 hours.

> Advanced efficiency—maximum number of cars processed in 24 hours rose from five to 49.

> Unparalleled access—IBX data centers’ 99.9999% uptime allows EB employees worldwide to access data on demand.

> Immense savings—decreasing the time test cars sit idle means more data and innovation, faster.

> Strengthened security—bypass storing data on the internet through colocation in secure and private IBX data centers.

> Heightened access—connect to and analyze multiple streams of data in real time, enabling advanced scenarios for connected vehicles.

> Location flexibility—upload data wherever test cars are, then ship it back to a central location.

Business overview

Elektrobit (EB) is a wholly owned subsidiary of Continental AG and employs approximately 2,600 people across three continents and 11 countries. With over 30 years in the industry, EB has become a leading innovator of the software that is moving connected cars and automated driving forward.

Business challenge

The amount of data needed to test and validate driver-assisted and automated driving functionality is continuously growing. One theoretical calculation places the amount of test miles needed for engineers to approve automated cars for market at 150 million miles on public roads.

With classical test driving, reaching this 150 million-mile mark would take more than 25 years. This is an unreasonable pace given the amount of data that timely advanced- driver assistance system (ADAS) innovation demands. Although conducting these test drives in a simulated cloud environment with 100 high-performance computers (HPCs) shortens this period to about five years, the same amount of test miles can now be accrued in just two weeks thanks to a cloud-based approach using 10,000 HPCs.

Automated vehicles running test drives and simulations can record roughly 10 to 20 TB of data in a single day, and potentially up to 100 TB/day with more advanced sensor sets. Figuring out how to securely store, transfer and process these large amounts of data has become a major industry roadblock, as upload times for many market options range from a week to several months for a single car.

These hurdles, plus the time needed to validate and check the data for completeness, further slows test vehicles from returning to work. Test cars sitting idle are extremely costly and in turn delay data from being made available to successfully test and validate ADAS functions.

"We worked closely with our customers to identify pain points in their current test process. What we learned is that the ADAS/AD workflow demands one toolchain to cover the whole process, from ingest to post-processing. We then built—from the ground up—a solution that solves this issue. Partnering with Equinix brings not only scalability, it also removes infrastructure redundancy and allows direct and flexible access to cloud partners like Microsoft Azure. This guarantees improved mobility, collaboration and a more reliable test process for our customers."

Martin Schleicher, Executive Vice President Business Management at Elektrobit

Solution

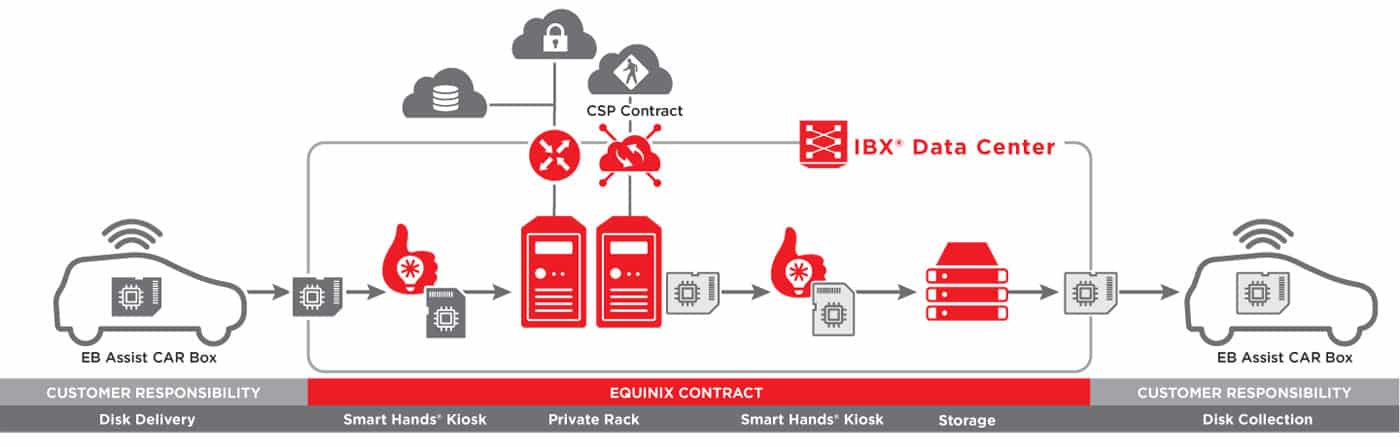

To design the solution and proof the concept, EB worked with Equinix Global Solutions Architects® to leverage the Equinix Solution Validation Center® (SVC®) at the Frankfurt (FR4) Equinix International Business Exchange™ (IBX®) data center. The SVC allowed EB to deploy and test its distributed IT live on Platform Equinix® before committing to full-scale implementation.

Concept: digital data garage

Solving for massive data ingest

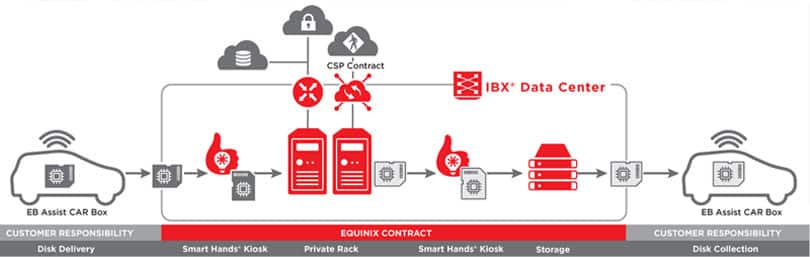

To serve as its upload station, EB installed an EB Assist CAR Box automotive PC system on-site at the IBX. When a prototype car equipped with measurement technology for capturing sensor data finished collecting data for the da, it drove to the IBX and physically handed off the data disk. These solid-state drives (SSDs) could also be shipped to any of the 200+ Equinix data centers via courier or logistics company.

The recorded data were then uploaded directly into the proverbial data garage within 14 hours via a high-bandwidth, low-latency link. Next, the relevant data were validated and uploaded into the Microsoft Azure cloud at a rate of 700 MBps. As this happened, the test car received a clean disk and drove off to collect more data. From here, the data on the cloud could be analyzed and incorporated into automotive software products and services by EB developers worldwide.

Value realized

This interconnection-first approach, deployed on Platform Equinix, provided EB thefastest and most stable option available. The company’s new position on the digital edge gave EB boosted efficienc, performance, reliability and security. IBX data centers also boast an industry-leading 99.9999% uptime record, allowing EB employees worldwide to access the data they need at any time.

Previously, data from 30 cars collecting ~19 TB a day took around 85 days to upload at 1 Gbps via public internet. Uploading the same amount of data via direct connect at 1–10 Gbps can still take between 6–47 days, handling data from no more than five carsin a 24-hour period. But uploading with a 10 Gbps upload rate in an Equinix IBX data center takes just 12 hours, or 49 cars per day. Excluding data validation, the upload rate to the cloud increased from around 10 MBps to 700+ MBps.

This new level of efficienc, along with the proven security and reliability found at IBX data centers, has put Elektrobit and its customers in position to innovate ADAS and AD technology at a speed previously unheard of.

Key take-aways

Uploading directly to an IBX was by far the most stable, efficient and cost-efective option on the market. In addition to faster upload and processing times, it sped up the development process by allowing exabytes of data to be better managed by collaborative teams that now find their workflows simplified.

With Equinix serving as the middle piece at the edge, terabytes or more of data can be piped in from EB overnight. This joint solution allows test drive data to quickly be processed and used by the EB customers to create the software products and services that are revolutionizing the automotive industry.

About Elektrobit

Elektrobit (EB) is an award-winning and visionary global supplier of embedded and connected software products and services for the automotive industry.

A leader in automotive software with over 30 years serving the industry, EB’s software powers over 1 billion devices in more than 100 million vehicles and offers flexible, innovative solutions forconnected car infrastructure, human machine interface (HMI) technologies, navigation, driver assistance, electronic control units (ECUs) and software engineering services. Elektrobit is a wholly owned subsidiary of Continental. Elektrobit is working with all major car manufacturers and suppliers.