CHASSIS WITH “BIG DATA“: NEW BUSINESS MODELS AND MORE TRANSPARENCY THROUGH SMART CHASSIS COMPONENTS

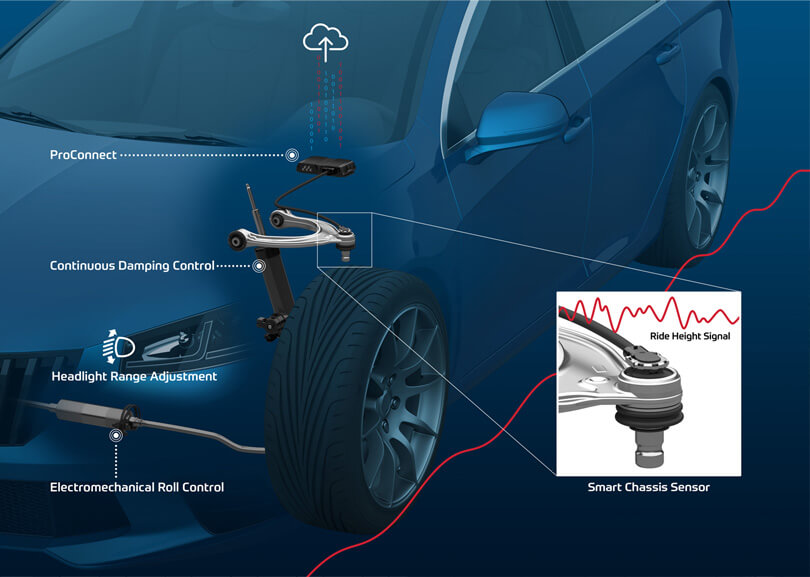

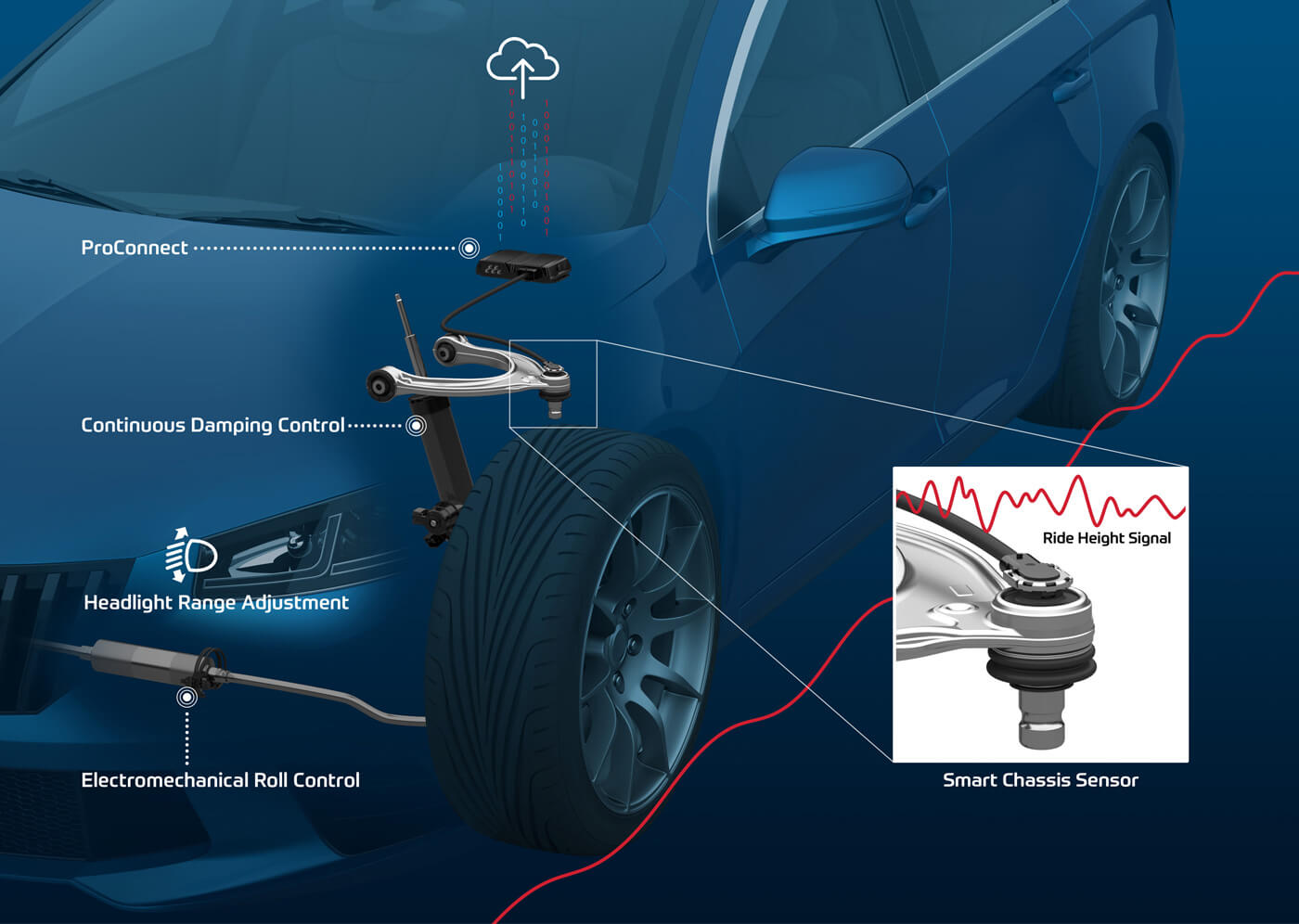

>> Height sensing with an innovative sensor module allows additional functions from intelligent chassis components

>> Data sensor measures the relative movement of the vehicle body and records mobility-relevant information

>> Increased efficiencies for fleet businesses, predictive maintenance, and analysis of road conditions

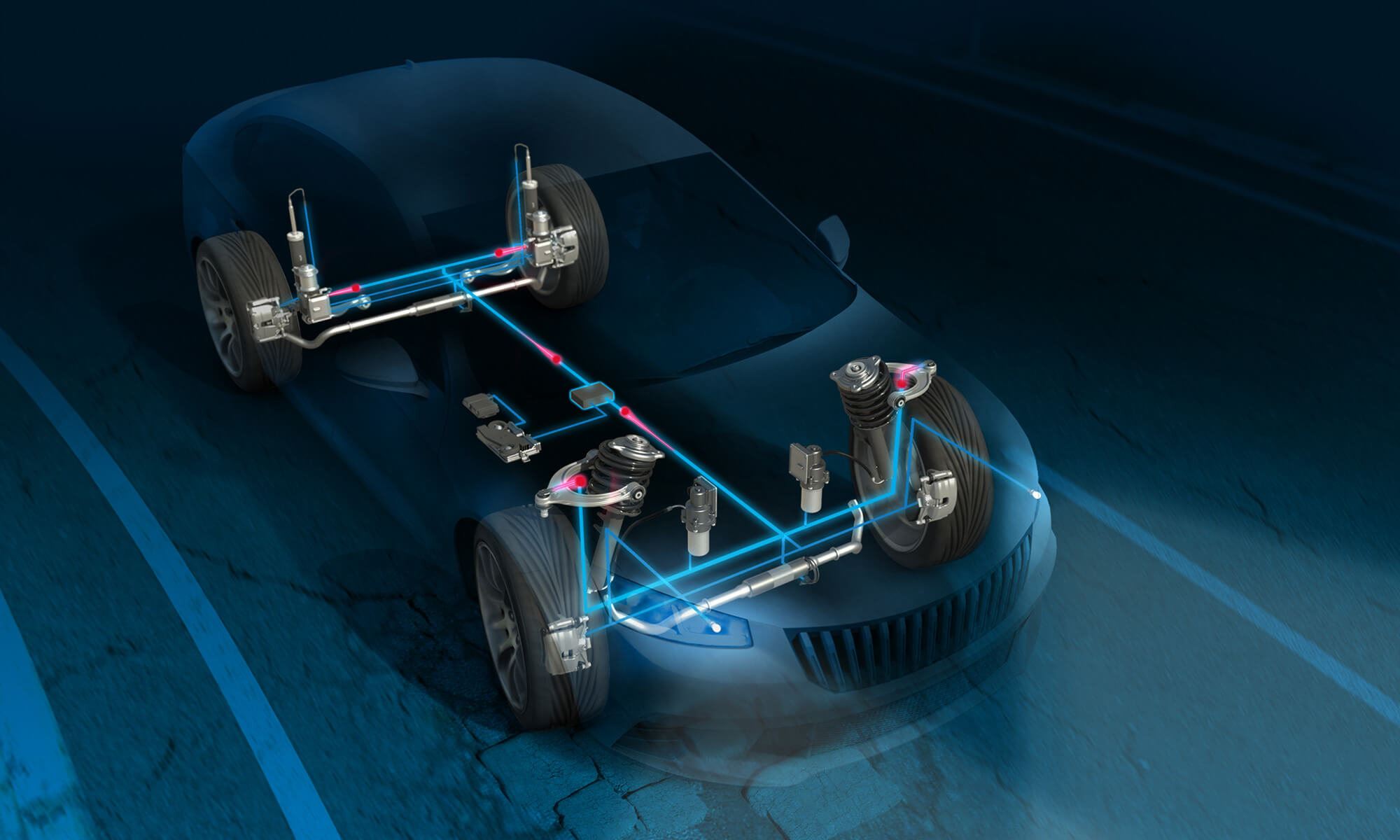

Friedrichshafen (Germany). Future generations of vehicles will become progressively automated and require an increasing number of powerful sensors – and therefore collect more and more data. Clever algorithms can generate information from this and even enable new business models. ZF enables this with extensive know-how in chassis technology and its sensor technology. The most recent example is the height level sensor integrated into a suspension control arm. Its functional diversity and data gathering capability extend far beyond its original purpose.

ZF's sensor already offers numerous advantages for car manufacturers compared to conventional height level sensors. Instead of being separately installed in the body, the sensor is integrated into the chassis bearing. Integral sensors are more robust, cheaper, lighter, easier to install and significantly more versatile. In addition to the dynamic headlight range adjustment, the sensor supports various semi-active and active systems for chassis regulation. The latest generation of the smart chassis component is planned to start production in 2023.

Ready for Data Business

ZF can significantly expand the scope of performance of the smart chassis components: "Our evaluation algorithms give sensors the intelligence they need to offer customers added value in very different areas," explains Steffen Reichelt, Head of the Chassis Components Product Line at ZF. "The data the sensor collects yields additional information about the vehicle, its surroundings and the road surface. These insights are especially valuable for commercial vehicle users and fleet owners as well as for road infrastructure maintenance."

From predictive maintenance to road condition monitoring

ZF is already developing the necessary software for this advanced data analysis. For example, with its memory for disruptive road features, the sensor captures where there are road defects, which can be used to adapt the chassis and help avoid damage. Also, the information from the sensor indicates the vehicle's own defects may have been caused by involuntary contact with a high curb. A visit to the repair shop can then help prevent downtime that is associated with high costs, especially in the case of commercial vehicles. The sensor is also able to detect differences in vehicle load - and thereby determine relevant information for electronic safety systems.

In addition, ZF could integrate further sensor functions into smart chassis components in the future and thus document the technical condition of a rental vehicle, for example. This is important if, in the future, more and more vehicles are operated by different users as part of new mobility concepts, without their condition being checked before or after a change of driver.

If the sensors become sufficiently widespread, the infrastructure will also benefit: the analyzed data can provide information about the condition of roads and bridges. Weak points such as cracks or potholes in the road surface can be found much more quickly and efficiently in this way.

"Our smart chassis components are important for the digital future of mobility," summarizes Steffen Reichelt. "With our series technology, we are already laying a foundation for 'Next Generation Mobility' today."