ZF SUPERCHARGES THE ELECTRIC FUTURE THROUGH SCALABLE ARCHITECTURES AND INTELLIGENT SOFTWARE

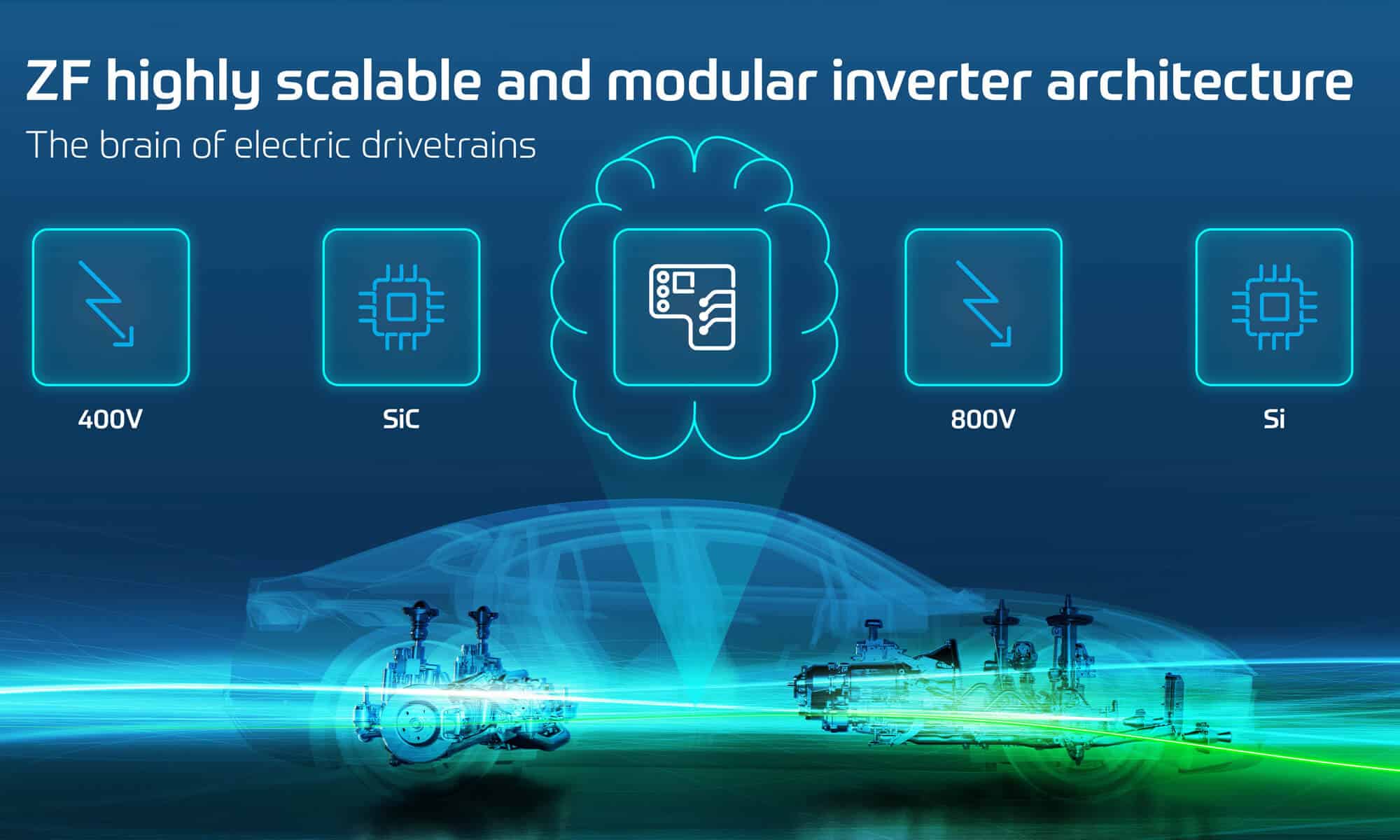

>> ZF has developed a scalable and modular e-motor inverter architecture that allows OEMs maximum flexibility from 400V to 800V, from Silicon-to-Silicon Carbide

>> Combines advanced inverter design, next generation power semiconductors and highly intelligent software algorithms

>> Leverages ZF’s deep experience in electric drives to increase efficiency, peak power and shorten development cycles

The inverter is the brain of electric drivetrains. It manages the flow of energy from battery to e-motor and vice versa. Inverters have become more efficient and more complex with every development step. The next evolution is the combination of the inverter design, next generation power semiconductors and highly intelligent software algorithms.

"The combination of greater scalability and modularity with increased efficiency, peak power and affordability of e-motors is the key to success within the e-mobility market," said Stephan von Schuckmann, member of the ZF Board of Management and responsible for the Electrified Powertrain Technology division. "The inverter is also where development cycles from the software industry and semiconductor innovations meet automotive hardware and integration expertise. This is where future differentiation will happen."

Modular and scalable inverter architecture

ZF has developed a highly scalable and modular inverter architecture that allows OEMs maximum flexibility in both 400V and 800V voltage classes.

The modular inverter platform is not dependent on predefined semiconductors and is designed to support vehicle manufacturers in bridging the Silicon-to-Silicon Carbide transition while also being prepared for future semiconductor trends.

ZF semiconductor and software innovation

ZF has been working toward the transition to alternative powertrain technologies for decades and has gained deep knowledge on the inner workings of e-drives, from the holistic design of e-drive systems to software optimization linked to new power semiconductor generations.

Efficiency and peak power of an inverter is not only defined by the properties of the power semiconductors, it is also significantly defined by software. Inverter technology and control software alignment is critical and can be achieved by several feedback loops, in which the inverter hardware provides the software a flow of information (current, temperature, DC-link voltage, etc.) which is used to optimize pulse patterns and switching strategies in real time to improve efficiency and peak power. Especially for Silicon Carbide based systems, ZF has found a solution optimizing the link between the power semiconductor boundary conditions and control software in order to gain the full potential from the semiconductor configuration.

As highlighted earlier the inverter contains the brain controlling the complete e-drive system. As with the human body you can train muscles and the brain to react more efficiently than normally, for example in sports or playing music. This is also what an inverter does - it flexes the e-drive in the most proficient and fastest way.

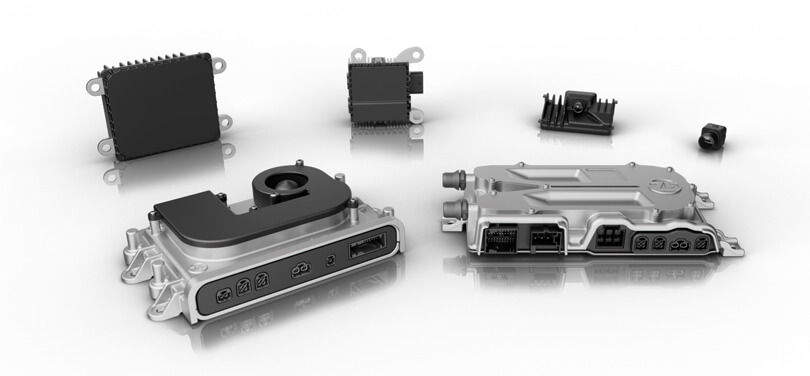

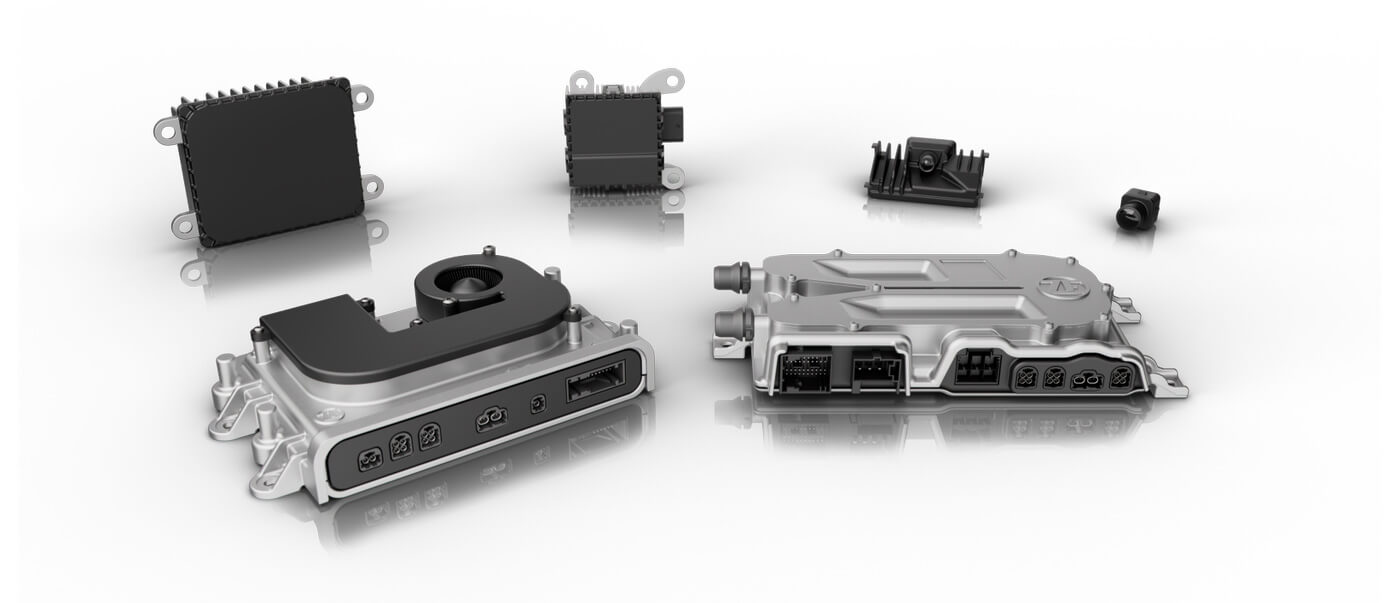

The control board within an inverter is the home of the inverter software – where the vehicles power demand is translated into the different digital control signals for the driver board that drives the power semiconductors according to the control signals. It is one of the key components of an inverter, because the gate drive technology is responsible for safety features, performance, efficiency and total range of the EV that can be squeezed out of the power semiconductors.

Our new inverter generation brings these hardware and software optimization functionalities to our customers to realize faster power semiconductor switching times, better short circuit protection and much more. ZF has built up significant knowledge in this area both independently and with strong partners such as WOLFSPEED.

Besides a highly scalable approach in terms of voltage and semiconductors, the clever usage of software and semiconductor advancements for inverters are key enablers of the ZF "Modular eDrive Kit" that can reduce the development time for new e-Drives by up to 50 Percent. This world first bundles the entire expertise of ZF's e-mobility team for system solutions, components, and software controls in a flexible and modular platform.

Experts in the path to electrification

"As the industry moves rapidly toward an electrified future and the goals of zero emissions to enhance our environmental future, ZF has the expertise and owns proprietary software and gate drive functions to accelerate the transformation. From significantly faster and safer short circuit protection to gate drivers realizing the absolute maximum performance of power semiconductors, ZF is well-positioned to fulfill the needs of the industry and society," emphasized von Schuckmann.

These inverter innovations are already being readied for next-generation e-drives that will be ready for production by 2025.

ZF DRIVES ADVANCED SAFETY AND AUTOMATED DRIVING INTELLIGENCE THROUGH SENSING AND SYSTEM EXPERTISE

>> ZF delivers advanced sensor technologies and intelligent functions that add value for consumers

>> Continuous expansion of the ZF ADAS sensor business

>> Next generation radar, camera and LiDAR systems coming to market

Las Vegas NV – ZF is a leader in the development of driver assist systems, providing intelligence, advanced safety and automated functions while expanding its business with leading global automakers and recent business awards.

"Our vehicle manufacturer customers are seeking advanced technology as well as the intelligence and functions that add value for consumers," said Martin Fischer, Member of the ZF Board of Management. We have been successful in steadily expanding our ADAS business through camera and radar contracts that include providing the fusion of those sensor technologies."

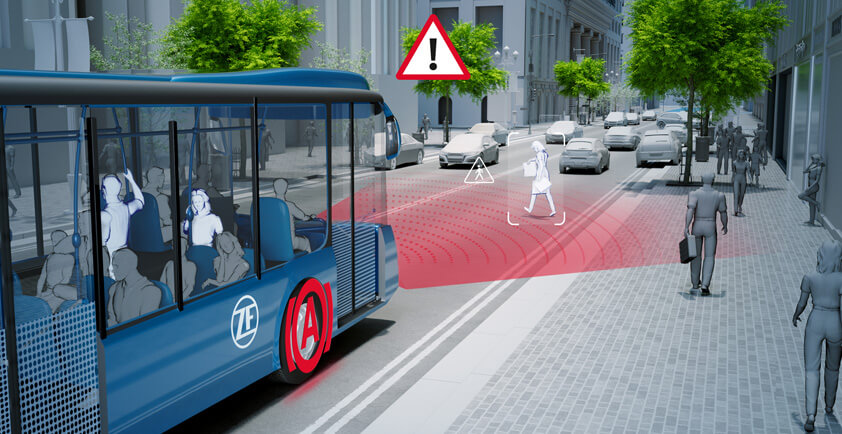

ZF is providing the foundation for autonomous driving through its sensor suite that includes its world-leading light vehicle forward-facing camera business featuring the S-Cam4.8, among the very first mass-produced single lens 100-degree field of view camera that is now being introduced across a range of customers. The wider field of view of the S-Cam 4.8 brings advantages, especially in sharp curves or at crossroads as significantly more vehicles are identified, and importantly vulnerable road users such as pedestrians and cyclists can be detected earlier.

ZF is introducing its next-generation radar portfolio that includes Mid-range radar and Full-Range Radar options, offering this key sensor in highly effective and affordable options and radars with enhanced sensing range and resolution. ZF’s Next Generation radar family includes options with advanced 3-d antennas as well as systems with remote radar heads that feed data into a central processor for 360- degree sensing at affordable costs.

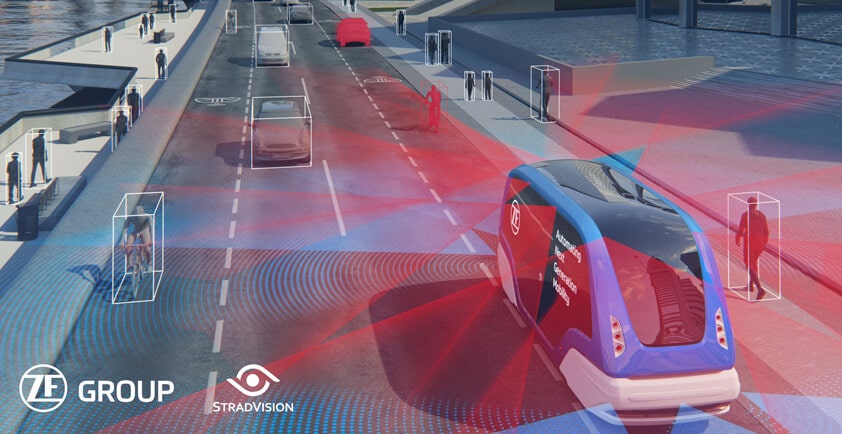

ZF’s sensor suite also includes LiDAR options to provide a third sensor for sensing the environment in more detail offering redundancy to camera and radar. Working with our partner Ibeo we will assist in the introduction of the solid-state IbeoNEXT LiDAR beginning in 2022 and have future LiDAR generations under development that balance excellent performance at reasonable cost. ZF has longstanding expertise in combining these technologies through sensor fusion and intelligently linking the data to enable advanced safety and automated driving functions while meeting global safety regulations.

"ZF is working with global automakers to deliver the advanced functions that contribute to the safety and convenience of drivers worldwide. ZF can deliver L2+ systems such as coASSIST, the most affordable L2+ system available that has already launched in China with Dongfeng, coDRIVE where we are working with customers to bring this enhanced L2+ system to market, and now will offer a coPILOT system to new customer VinFast that offers L3 functions scalable to L4 for automated parking. All evidence that Next Generation Mobility is being realized now," Fischer said.

ZF PREMIERES VEHICLE MOTION CONTROL HIGH-PERFORMANCE COMPUTING PLATFORM

>> ZF introduces its next high-performance central computer – the Vehicle Motion Domain Controller

>> Coordinates chassis and vehicle functions from a single unit and integrates vehicle body control functions without the need of additional ECUs

>> New addition to ZF’s family of supercomputers joining the ProAI

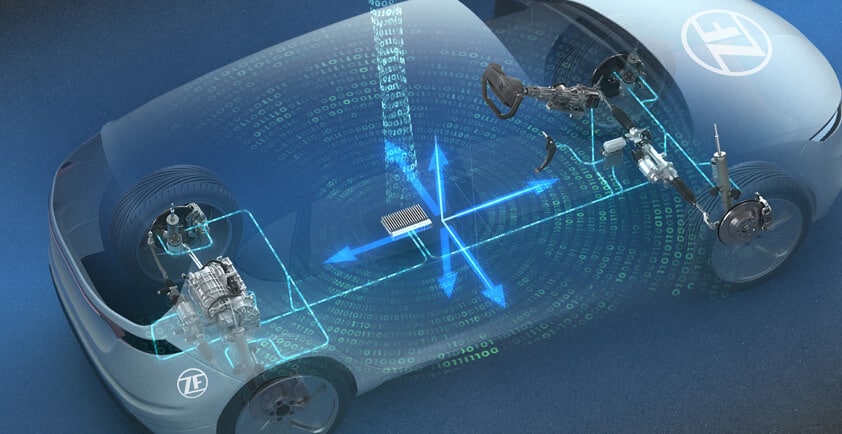

Las Vegas, NV. At CES 2022, ZF introduces its next high-performance computing platform – the Vehicle Motion Domain (VMD) Controller. The VMD Controller is a central computer adaptable for all types of chassis platforms, vehicle motion and body functions, next generation software defined cars and future domain and zone E/E architectures.

A car's ride and handling characteristics are largely defined by its chassis. Wheel guidance, damping, suspension, steering and brakes help determine the character of a vehicle and the trend toward the electrification and software control of these systems continues to accelerate.

"Carefully coordinated driving dynamics are essential to enhanced safety and comfort for both piloted and autonomous driving. Customers today are choosing among a broader spectrum of technologies that require more sensing from integrated chassis sensors as well as other vehicle systems. Meeting the increased requirements of these increasingly sophisticated systems that include redundant circuits need higher powered computing solutions," says André Engelke, head of the Vehicle Motion Control system House.

"That’s why we have developed the VMD controller, which we believe is currently the most flexible, scalable and powerful chassis domain high performance computer available," Engelke emphasized.

The high-performance controller is designed to integrate vehicle functions across domains including body and power management and supports standalone functionality while reducing complexity by using a single controller for intelligent vehicle motion control. The VMD Controller serves the software defined vehicle trend with real time functions and applications with a high-performance threshold of 55,000 DMIPS (draystone million instructions per second).

ZF also places great emphasis on open systems that allow mobility customers to adjust components according to their needs. For a higher level of automation, the VMD high-performance controller can be connected to ZF ProAI, ZF’s high performance computing platform for ADAS/AD applications, in an integrated system approach.

"The design and architecture of the new version of the ZF VMD Controller is, of course, based on this open and modular approach: The board can operate ZF’s own application and safety software – or that of other developers or third-party suppliers," Engelke said.

ZF high-performance supercomputers designed for a dynamic future

The intelligence of future vehicles are likely to be controlled by a few extremely powerful central computers such as the VMD and the ProAI controllers. They run the computationally intensive software functions that control critical vehicle domains and help enable functions for automated driving, electric mobility, vehicle motion control and integrated safety. High-performance computers and intelligent software functions are key enablers for the software-defined vehicles of the future and can help bring safe and smart mobility experiences to contemporary consumers.

With the latest generation of the ZF ProAI supercomputer, ZF presents the next level of the most flexible, scalable, and powerful automotive-grade supercomputer in the world. With a 66 percent increase in computing power, the new ZF ProAI consumes up to 70 percent less power. The core of new E/E vehicle architectures is formed by high-performance computers which can be used either as central, domain or zone controllers.

"Our ProAI is designed to cover a wide range of possible application fields for virtually all vehicle types and for all envisaged stages of automated or autonomous driving," explains Torsten Gollewski, Executive Vice President Autonomous Mobility Systems at ZF. "And as we add new specialized controllers like the VMD we can help the industry meet the demands of new vehicle architectures and advanced functions that will enhance next generation mobility."