IAA PREMIERES: ZF SETS THE PACE FOR SUSTAINABLE MOBILITY

>> World premiere: At IAA Mobility, ZF presents the Modular eDrive Kit, which reduces the development time for new e-drives by up to 50 percent.

>> ZF is robustly driving sustainability in mobility - from production and supply chain through product offerings and solutions - to mobility offerings for employees

Munich. At IAA Mobility in Munich, ZF, as a comprehensive system provider for sustainable mobility, presents its innovations - setting the tone for e-mobility and powerful central computers.

"Next Generation Mobility. Now." - Seldom has a ZF motto been so fitting as is it is for IAA Mobility 2021 in Munich - when society's mobility needs are in a state of upheaval. However, ZF sees great potential for the future of mobility. The technology group is therefore focusing on sustainable and comprehensive new mobility and driveline concepts. The technologies for these are already available. Under the auspices of IAA, ZF presents both a world premiere and a European premiere.

"Sustainable mobility is becoming tangible for people. With its products and solutions, ZF is helping to establish this in society, making it increasingly visible in everyday life," says ZF CEO Wolf-Henning Scheider at IAA Mobility. "Never before has an IAA been better suited to talk about mobility as a whole. This suits us at ZF very well, because we are at home in almost all areas of mobility."

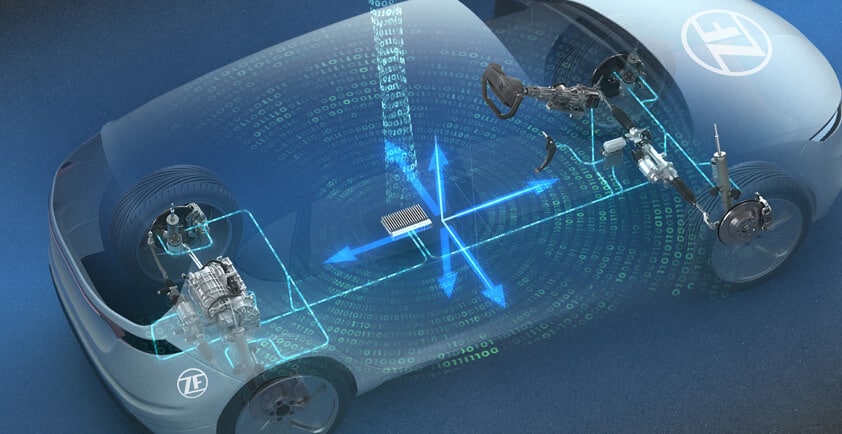

World premiere: Modular eDrive Kit

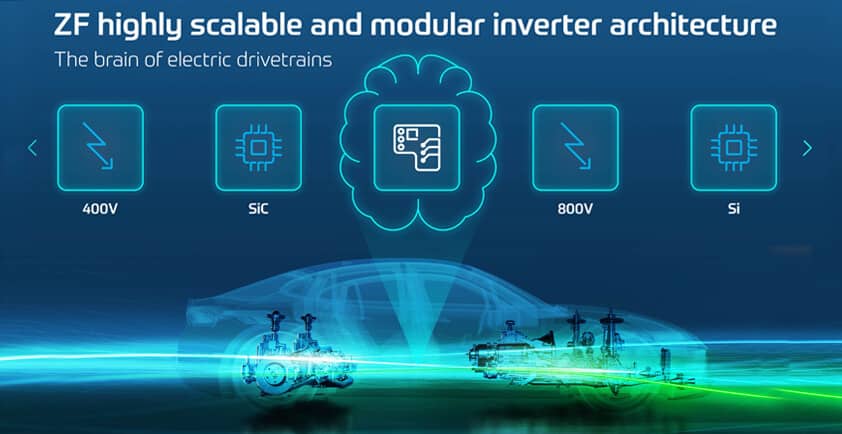

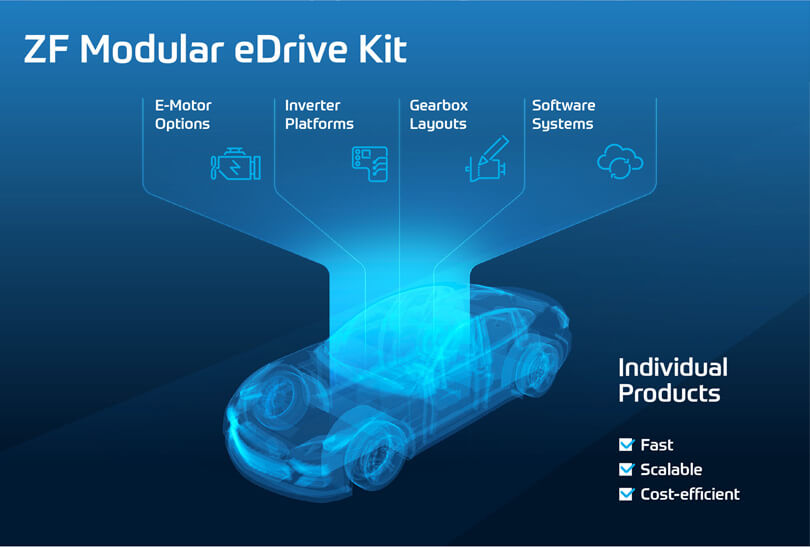

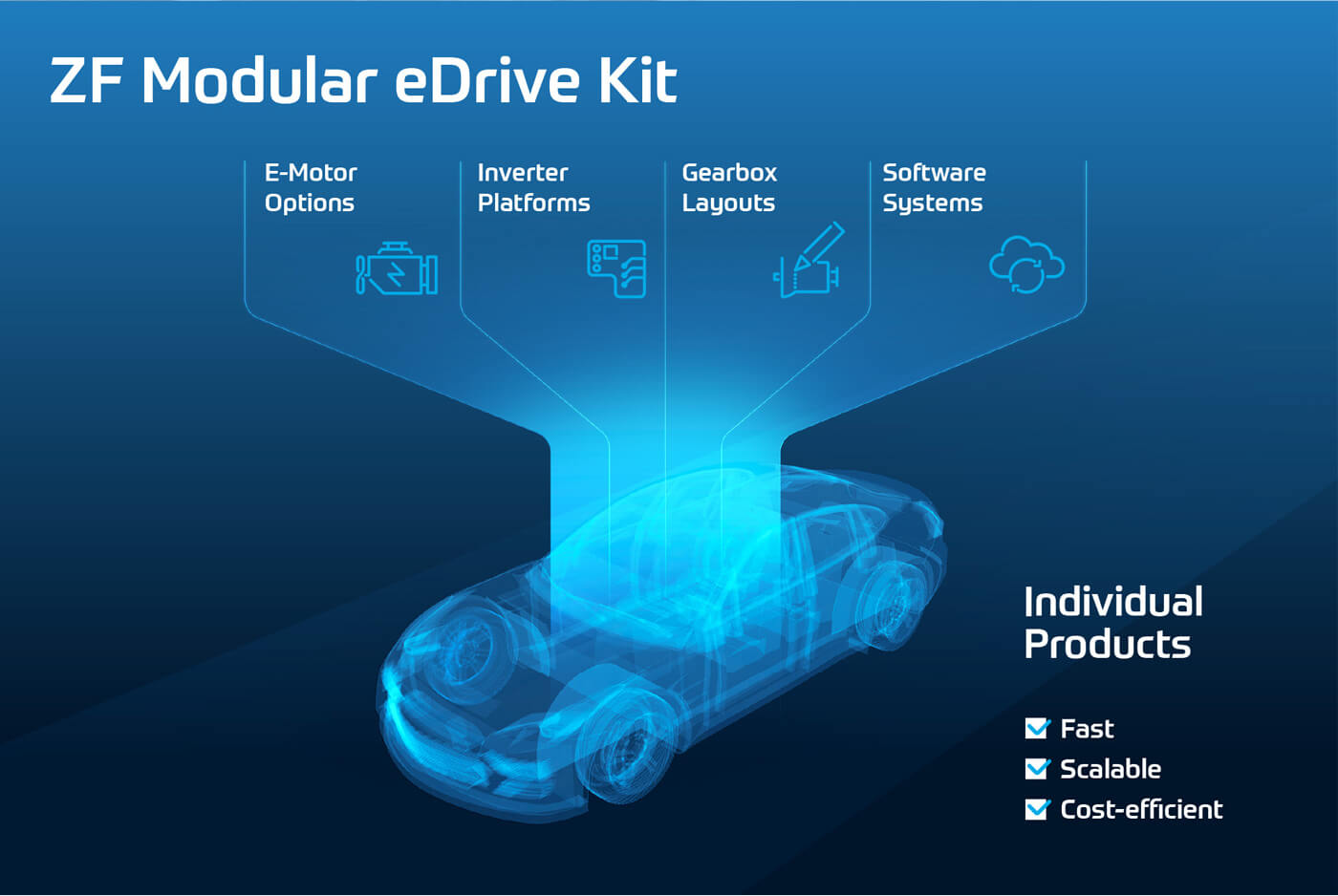

The world premiere of the Modular eDrive Kit shows just how powerful ZF is in the e-mobility arena. It bundles the entire expertise of ZF's e-mobility team into systems solutions, components and software control in a flexible platform. All new e-drives of the Modular eDrive Kit offer significant improvements in power density, weight, and efficiency. Optimized transmissions, as well as highly efficient cooling and lubrication concepts, reduce mechanical losses by up to 70 percent. To achieve this, ZF draws on its particular expertise in the field of transmissions. In addition, patented innovations in power electronics are included in the modular system. This offers tangible advantages for the automotive industry: "Among all the key figures of our Modular eDrive Kit, one is most important to us: The 50th percentile. Because we reduce the development times for new e-drives by up to 50 percent. We achieve this through a common technical base and cross-platform development of the components, through synergy effects and with a higher degree of maturity from the very beginning," explained Scheider.

ZF’s Modular eDrive Kit also gives manufacturers a great deal of leeway in the design priorities between maximum performance and efficiency because it offers the widest possible spread - from compact cars to the premium segment: Configurations from 75 to 400 kW of power and from 350 to 540 Nm of torque are possible. The consistent modular approach of the Modular eDrive Kit serves as an optimal complement to the platform strategies for ZF customers: from established vehicle manufacturers to new automotive customers and tech companies. As a result, ZF now offers the exact foundation automotive manufacturers need for the next generation of battery electric vehicles.

Green Power Roadmap: Climate neutral ten years earlier

ZF has secured, in a Green Power Roadmap, how all ZF activities will become climate-neutral by 2040 - ten years earlier than envisaged in the Paris Climate Agreement.

Sustainability is an obligatory criterion for ZF - as an important milestone, CO2 emissions at ZF locations are to be reduced by 80 percent by 2030 compared to 2019. ZF also assumes responsibility for its supply chain and the use phase of its products. The goal: to reduce, by 2030, the so-called Scope 3 emissions by 40 percent compared to 2019.

And employees can also play a pioneering role: Already, 80 percent of newly ordered company cars at ZF in Germany are electrified. In addition, ZF subsidizes the installation of private charging facilities for company cars. Furthermore, there will be workplace charging facilitites at every ZF location, worldwide, by the end of 2021. In Germany, more than 50,000 employees can also lease through ZF, a bicycle or e-bike.

"And that's not all: we are also playing a major role in shaping the generation of energy from renewable sources," said Wolf-Henning Scheider. "Today, 25 percent of all wind turbines already contain a ZF transmission. These turbines alone can supply up to 100 million households with renewable energy - and another million are added every month."

IAA MOBILITY DEEP DIVE: AUTOMATED AND AUTONOMOUS DRIVING

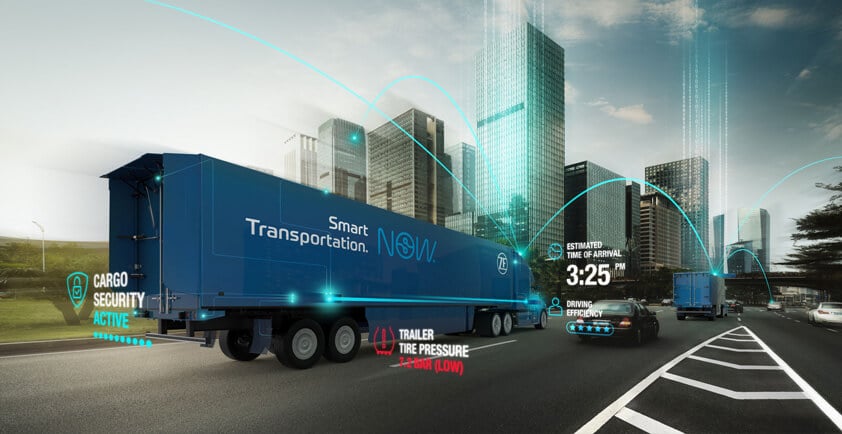

>> ZF technology makes automated and autonomous driving functions possible for a wide range of applications

>> European premiere: ZF ProAI supercomputer for vehicles from level 2 to level 5

Control units, software, sensors and actuators for the software-defined vehicle and new mobility concepts

Munich. Under the motto "Next Generation Mobility. NOW. ", ZF is focusing on automated driving functions, along with other innovations, at the IAA 2021. With the new model of the supercomputer ZF ProAI, the company already offers the basis for autonomous driving up to Level 5. In addition, the Group has its sights set on new mobility offerings - such as autonomous shuttle systems as a supplement to public transport.

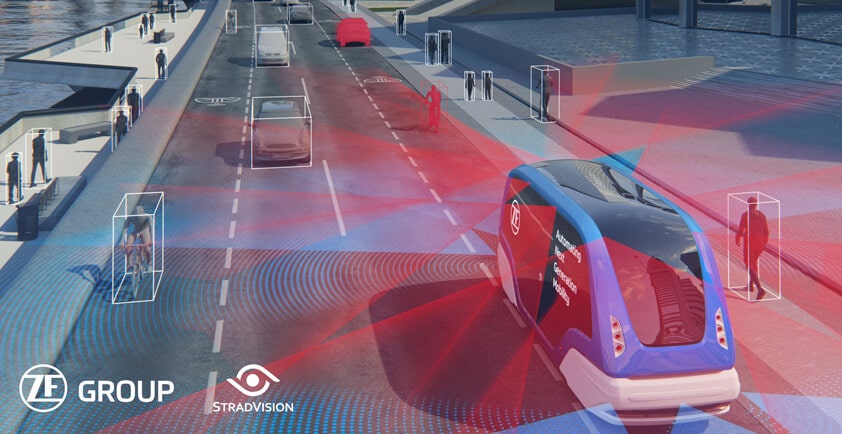

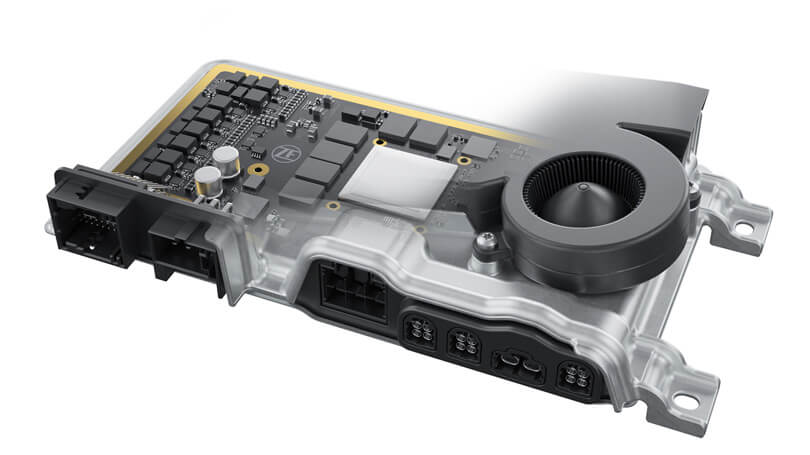

The core of new E/E vehicle architectures, such as those required for autonomous driving functions, are high-performance computers that can be used either as central computers or domain or zone ECUs. This is where ZF comes in with its ZF ProAI supercomputer, which the Group is presenting for the first time in Europe at the IAA.

“Our strategic goal is to provide technology for 'Next Generation Mobility',” explains Torsten Gollewski, Executive Vice President Autonomous Mobility Systems at ZF. “We already have all the necessary technologies for the vehicle and mobility concepts of tomorrow. Our ProAI covers an enormous breadth of possible application fields for every vehicle type and is suitable for all stages of automated or autonomous driving.”

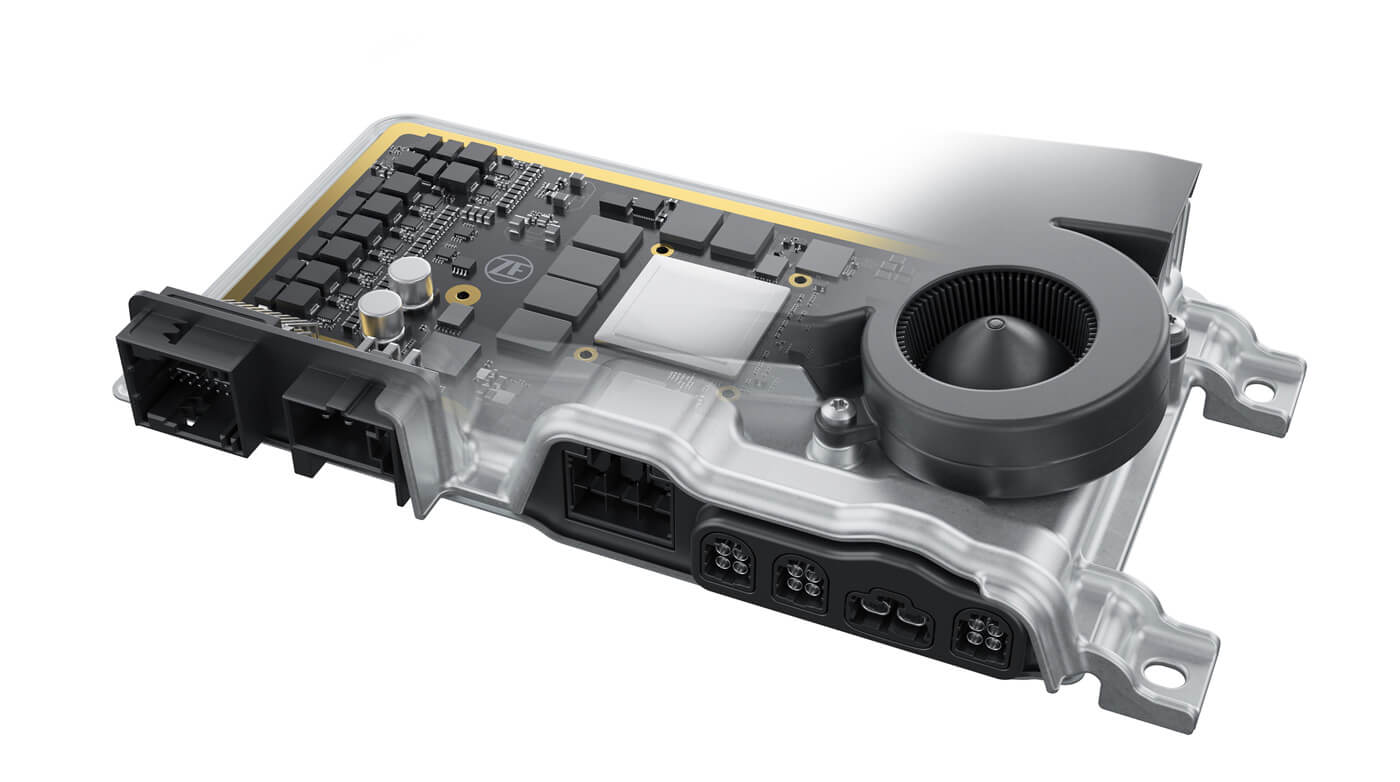

ProAI is currently the most flexible and powerful high-performance computer for the automotive industry. With up to 66 percent more computing power, the ZF ProAI requires up to 70 percent less power than its predecessor. The AI capabilities of the ZF ProAI are optimized for Deep Learning and are an important basis for new and enhanced safety functions. The computer offers a GPU-driven 360° fusion of all available sensor data, including ambient measurement data from cameras, radars, LiDARs and audio patterns.

In addition, the new generation is even more compact and thus requires less installation space: the uniform platform measuring just 24 x 14 x 5 cm takes up less space than an iPad. In line with the requirements of the automotive industry, the high-tech interior is designed for maximum resilience and reliability even under extreme conditions and offers the latest security mechanisms against cyber threats. Thanks to its modular design, the supercomputer can be equipped with "system-on-chip" (SoC) variants, i.e. with processors from different manufacturers, depending on customer requirements. It can also be operated with software from ZF or from third-party suppliers. Standardized connectors and the possibility to connect several ZF ProAI units with each other make it flexible for packaging in nearly any type of vehicle.

ZF's high-performance computer offers flexible computing power of up to 1000 Tera-OPS – which corresponds to up to one quadrillion computing steps per second. ZF has already won the first major orders for the ZF ProAI in both the passenger car and commercial vehicle segments and will produce the central computer in large-scale production starting in 2024.

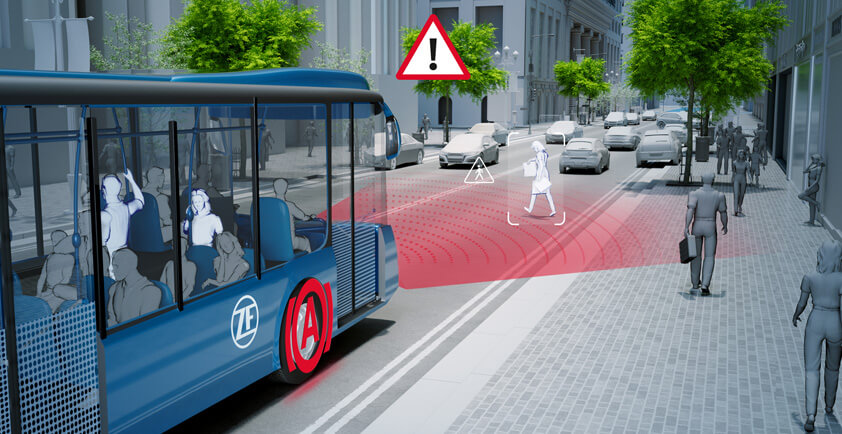

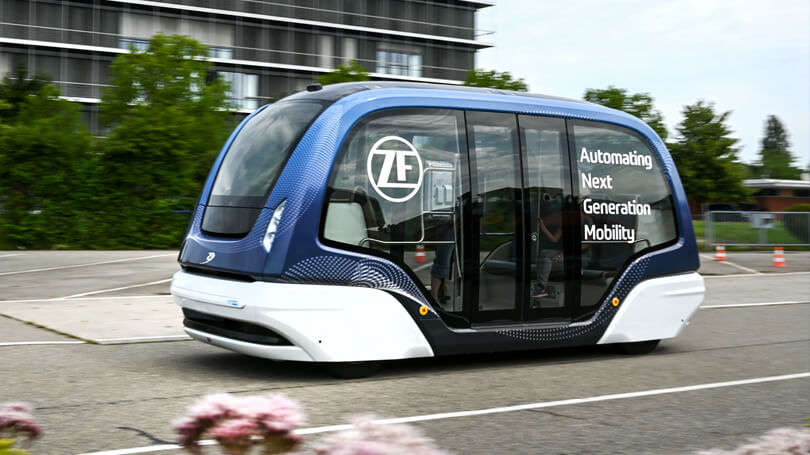

Autonomous shuttle systems

In addition to ZF ProAI, the Group already offers the necessary technologies for future autonomous vehicle and mobility concepts. For example, the Group is very active in the market for autonomous shuttle systems. ZF has acquired 100 percent of the Dutch company 2getthere, which has many years of experience with autonomous driving systems – as evidenced by 14 million passengers transported and over 100 million kilometres travelled autonomously. ZF is currently in the process of developing autonomous shuttles for the German cities of Friedrichshafen and Mannheim as part of the RABus project. At the Rivium Business Park near Rotterdam, where 2getthere's autonomous shuttles have been in operation for years, ZF is currently updating them with the latest version.

“A network of autonomous, electric shuttles available via app can usefully supplement existing public transport services in cities, but also better connect rural areas to cities,” says Torsten Gollewski.

This will make mobility more sustainable by helping to prevent congestion and emissions and improving people's quality of life.