VISTEON COMPLEMENTS INDUSTRY-FIRST SMART WIRELESS BATTERY MANAGEMENT SYSTEM WITH ADDITIONAL ELECTRIFICATION TECHNOLOGY

>> Electrification electronics designed to support global growth of electric vehicles

>> Power electronics capabilities beyond smartBMS innovation

>> Visteon BMS systems provide OEMs with scalability across brands and vehicle segments

LAS VEGAS, – Visteon, a leading global technology company serving the mobility industry, will showcase its suite of electrification electronics designed to support the global growth of electric vehicles and the electrification trends of OEM customers at CES.

As the global mobility industry undergoes a once-in-a-century electric transformation, Visteon is evolving its electrification electronics capabilities to include a variety of intelligent systems for battery management and integrated power electronics.

"Visteon’s history of producing battery management systems and digital cockpit electronics places us in a good position to support the industry’s shift to electrification. Our first-to-market smart wireless battery management system (smartBMS) solution is the centerpiece of a growing electrified product line that will help automakers reduce the complexity, weight and materials used to manufacture electric vehicles and enhance the ownership experience for their customers." Sachin Lawande, President & CEO, Visteon

Battery Management System (BMS)

Visteon’s BMS capability dates back to the earliest days of EV production when it supported the 1998 Ford Ranger EV and various other automakers since then. In 2020, Visteon transformed its wired BMS solution into a first-to-market smart system that communicates wirelessly to key EV components.

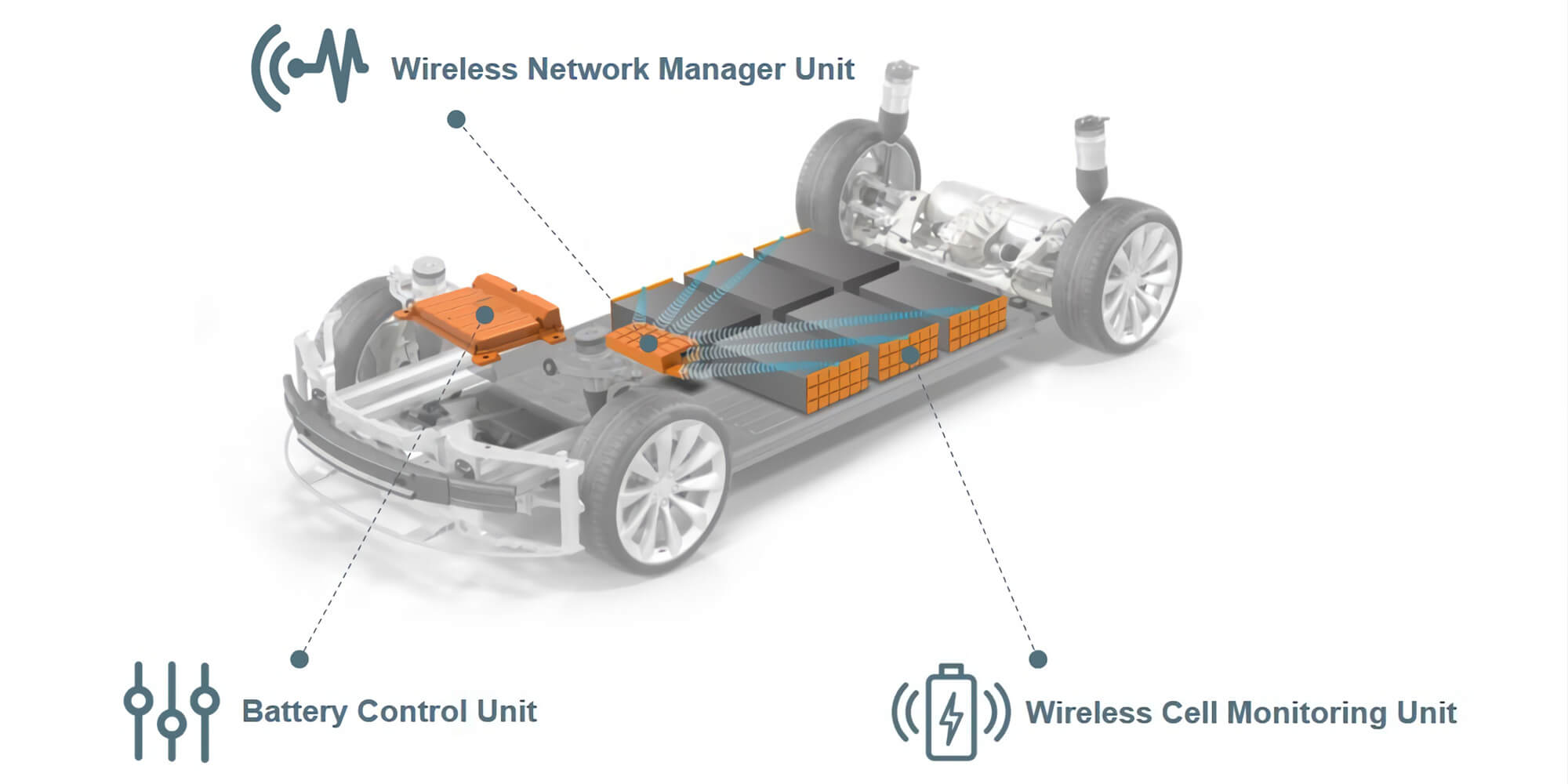

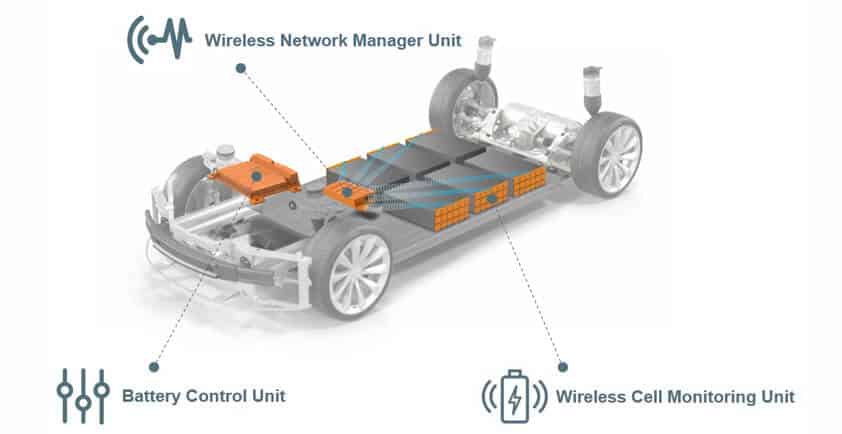

Wireless BMS technology replaces traditional wired connections with a highly secure and reliable wireless communication technology. Visteon builds its wireless cell monitoring/supervising units with a wireless network control unit and a battery control and interface unit, eliminating the need for OEMs to assemble battery packs with a low-voltage wiring harness. This can reduce overall vehicle weight and offer scalability across brands and vehicle segments. The smartBMS system platform delivers highly accurate battery cell measurement and maximizes energy use per cell required for better vehicle range.

Visteon’s wireless smartBMS can help automakers drive EVs to market faster, as time will not be needed to develop specific communication systems or redesign complex wiring schemes for each new vehicle. Instead, the wireless system will help to ensure the scalability of batteries across future EV lineups encompassing different brands and vehicle segments, from heavy duty trucks to performance vehicles.

Because the integrated hardware architecture and system software can extend across multiple vehicle platforms with minimal module configuration changes, this flexible wireless solution reduces engineering costs significantly and can more easily be integrated with thermal management systems and other vehicle controls.

The wireless smartBMS keeps a constant eye on battery health and operation, helping automakers enhance vehicle and passenger safety and improve overall quality and reliability. Visteon’s smart cell sensing controller adds extra processing capability to the battery-monitoring network that enables advanced diagnostics and more flexibility for future applications and algorithms.

General Motors uses the Visteon wireless BMS technology on all of its planned EV models powered by Ultium batteries. A second global OEM will use the Visteon wireless BMS on its EV launches starting in 2024. The company continues to offer its smart wired BMS system with advance features to automakers.

Intelligent Electrification Electronics Beyond smartBMS

Visteon is working to grow is electrification capabilities beyond its smart wired and wireless BMS solutions. The company’s CES display will demonstrate innovations that can be used to optimize EV design and performance of EVs, including:

> Smart junction box, a more cost effective and safer alternative to traditional battery disconnect units (BDUs). The smart junction box combines the traditional BDU with the battery management controller (BMC) to help lower cost, increase safety and create higher volumetric efficiency. The single unit performs all the functions of standalone BDUs and BMCs, including fusing, pre-charging, external charging, voltage sensing, temperature control, diagnostic, terminal interfacing and more.

The integrated solution is compatible with 400V and 800V systems, reduces high-voltage harnesses and connectors, and meets the highest Automotive Safety Integrity Levels for electric current and voltage measurement.

By combining a traditional BDU with a range of other electronics into a single integrated unit, Visteon’s customers reduce complexity, decrease mass and weight, and offer added protection for electrical connections.

> Integrated power electronics that combine key components into a single integrated unit through power stage integration to help reduce cost and size, and increase reliability and efficiency. Visteon’s multi-component design brings several key components used in EVs including the junction box, DC/DC converter and on-board charger into a single unit. Visteon’s single package design helps reduce EV architecture complexity by minimizing electrical connections, wire harnesses, and other connectors while also integrating system communication and a simplified cooling mechanism.

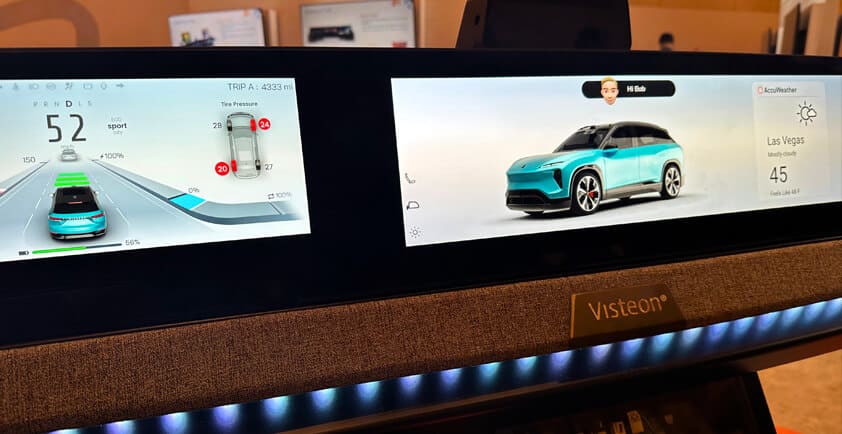

"Visteon has a passion for innovation and a clear vision for the future of electrification in the mobility industry. Our intelligent electrification capability is complemented by our cockpit electronics portfolio of digital clusters, Android-based infotainment, advanced display technologies and SmartCore™ domain controllers that lead to more enjoyable, connected and safe driving experiences in all types of EVs." Sachin Lawande, President & CEO, Visteon