SCHAEFFLER AND MOBILEYE TO INDUSTRIALIZE SELF-DRIVING SHUTTLES

>> The collaboration pairs the engineering and industrialization expertise in the drivetrain and chassis fields from Schaeffler with Mobileye’s longstanding know-how and leadership in driver assistance and autonomous driving systems

>> Self-driving, highly flexible and customizable vehicle platform will be available from 2023

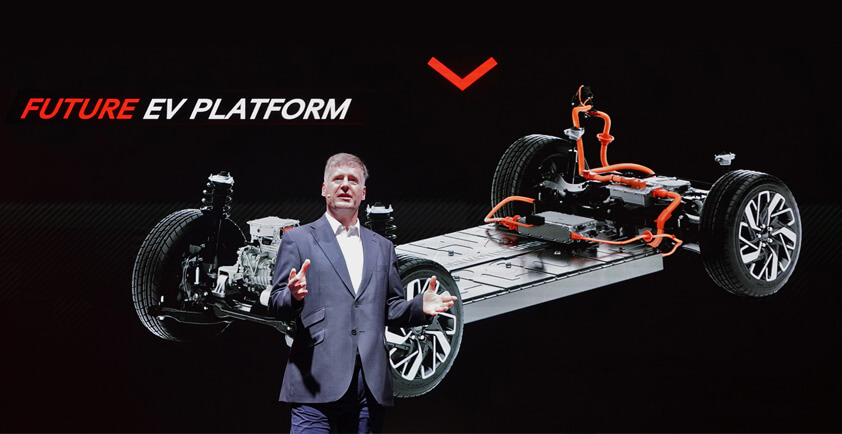

The automotive and industrial supplier Schaeffler and Mobileye, an Intel Company and leading provider of automated driving solutions, have agreed on a long-term cooperation. "Rapid regulatory and technological change, increasing urbanization and growing social awareness of mobility are increasing the need for alternative, novel concepts such as autonomous people or logistics movers," says Matthias Zink, CEO Automotive Technologies at Schaeffler AG. "They play a crucial role in sustainable mobility and are a future field in our Roadmap 2025. With the partnership with Mobileye, we want to develop autonomous shuttles to series production."

The rolling chassis from Schaeffler, a modular platform for new mobility concepts, is combined with the Mobileye Drive™ self-driving system. The goal: to develop a new, flexible platform for self-driving shuttles and other vehicle products at full automation level 4 and to offer customers worldwide solutions for Mobility-as-a-Service (MaaS) and Transportation-as-a-Service (TaaS). “Mobileye Drive™ is a versatile, scalable solution that enables any vehicle type to become self-driving. The new and innovative Schaeffler rolling chassis vehicle platform equipped with Mobileye Drive will enable broad deployment of autonomous shuttles and other driverless transportation solutions starting in the next couple of years," says Johann Jungwirth, Vice President of Mobility-as-a-Service at Mobileye.

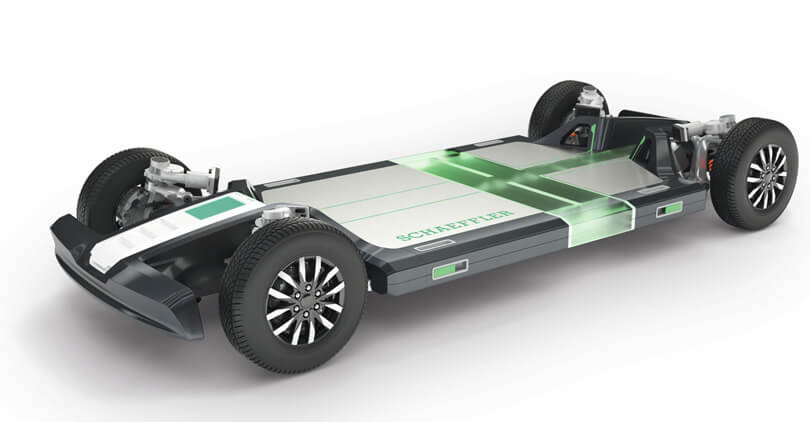

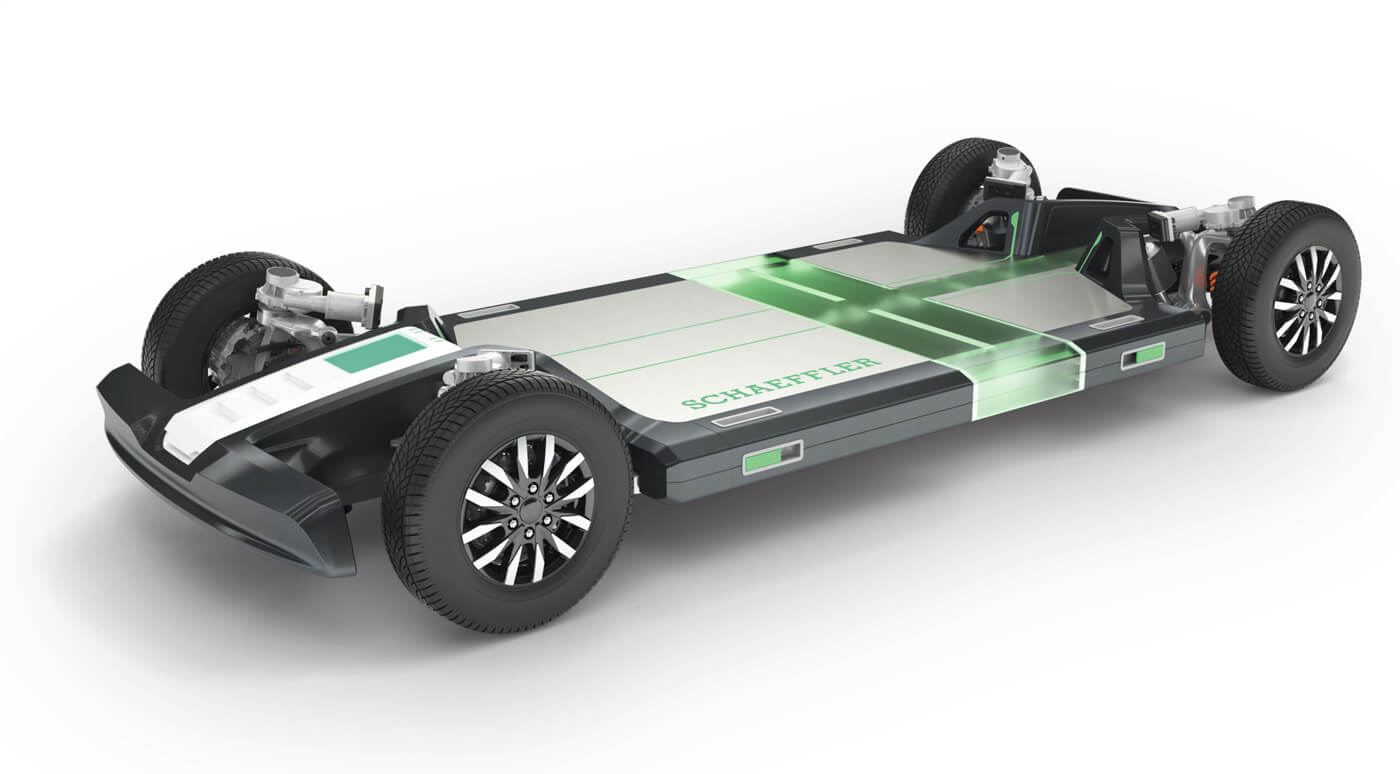

The Rolling Chassis from Schaeffler is a flexible, scalable platform for new, driverless mobility solutions

Autonomous transport solutions from 2023

By combining Mobileye's AV technology with Schaeffler's rolling chassis, both companies can offer an autonomous, highly flexible and adaptable vehicle platform that meets automotive safety standards with the necessary redundancies and thus enables the rapid scaling of autonomous transport solutions from 2023. Mobility service providers and transportation of goods companies will thus pave the way for the introduction of autonomous shuttles economically viable, as operating times and efficiency can be significantly increased.

The Rolling Chassis from Schaeffler is a flexible, scalable platform for new, driverless mobility solutions for the transport of people or goods or for special applications such as mobile charging solutions or pop-up stores on wheels. The modular platform shows the wide range of technologies from Schaeffler and offers a flexible architecture: Regarding steering and drive, a wide variety of variants can be implemented depending on customer requirements – from a simple drivetrain via an e-axis and central steering to the use of four "Schaeffler Corner Modules". The corner modules, which each allow a steering angle of up to 90 degrees, have been further developed in the direction of series production and scalability. They include the wheel hub motor, the wheel suspension including air suspension, which makes it possible to lower the vehicle for entry, the actuator for the electromechanical steering and a brake.

The Mobileye Drive™ self-driving system is a turnkey AV solution that delivers safety via two core concepts: Mobileye’s formal Responsibility-Sensitive Safety model for the safety of the system’s decision-making, and a perception system featuring True Redundancy™ whereby two independent subsystems (cameras and radars+lidars) combine to enable robust perception. The self-driving system can also be deployed without geographical limitation thanks to Mobileye’s Road Experience Management™ AV mapping technology through which a proprietary, crowdsourced AV map of the global road network is created and then continuously and automatically updated using data gathered from mass-market advanced driver-assistance systems.

SCHAEFFLER CHASSIS SOLUTIONS SMOOTH THE WAY FOR AUTONOMOUS MOBILITY

>> Space Drive 3 Add-ON: next-generation steer-by-wire technology supports simplified integration into existing vehicle architectures and reaches maturity for commercialization

>> Schaeffler handwheel actuator (HWA) replaces conventional steering wheel and mechanical steering column with mechatronic actuators, opening up new possibilities for cab interior layout

>> New rolling chassis as scalable platform for driverless mobility

Schaeffler is steadily expanding its involvement in autonomous mobility based on intelligent chassis systems. At IAA Mobility 2021, the automotive and industrial supplier will be unveiling Space Drive 3 Add-ON, the third generation of its Space Drive drive-by-wire system, a multiple redundant technology that paves the way for autonomous driving. The showcase highlights the technology’s maturity for commercialization. The mechatronic systems on display will include the premiere of Schaeffler’s force-feedback handwheel (HWA), as well as its safety and comfort-enhancing intelligent rear wheel steering (iRWS) technology. Schaeffler will also be presenting its new rolling chassis, a vehicle platform that opens the way to completely new forms of autonomous mobility. “Thanks to our work in this area, we are fast becoming the technology partner of choice for highly integrated chassis solutions,” said Matthias Zink, Schaeffler’s CEO Automotive Technologies. “Combined with our electric drive technologies, these solutions represent pioneering innovations in autonomous mobility. The key to it all is the wealth of expertise in components and systems that we have amassed over many decades and that we are now able to apply at the whole-vehicle level.”

Space Drive steer-by-wire system ready for production

Schaeffler’s Space Drive steer-by-wire system transmits driving and steering commands to the vehicle wheels via purely electronic signals, opening the way for autonomous driving. The technology has been proven in the field, with more than a billion accident-free kilometers driven so far, and is undergoing fine-tuning under extreme conditions in motorsport applications. The latest generation of this technology, Space Drive 3 Add-ON, is ready for small-volume production and will be on show at IAA Mobility. The Space Drive system is triple redundant for maximum safety and meets the exacting functional safety requirements of ISO 26262. Generation 3 is based on the AUTOSAR software standard, meaning it can interface directly with vehicle electronics and onboard communication and network architectures, enabling it to be integrated into existing vehicle assistance systems. “Space Drive 3 is a major milestone for us,” explained Viktor Molnar, Head of Chassis Systems at Schaeffler. “It means we can offer our customers a production-ready steer-by-wire system that is highly scalable and extremely flexible. What’s more, the system can record every steering parameter, which in self-driving vehicles enables feedback for the advanced driver assistance system (ADAS).”

Mechatronic solutions for enhanced comfort and safety

At the upcoming IAA Mobility show, Schaeffler will be unveiling its force-feedback handwheel actuator (HWA), a mechatronic solution that replaces the conventional steering wheel and mechanical steering column. This reduces the amount of space required for the steering system and opens up completely new possibilities for the design of cab interiors – such as the ability to stow the wheel in the center console when in (semi-)autonomous driving mode. The system can suppress undesirable feedback, such as vibrations from uneven road surfaces, and supports variable steering gear ratios, enabling new driving dynamics functions. The HWA is also modular and scalable, so it can be adapted to various applications and classes of vehicle. Combined with the Space Drive steer-by-wire system and mechatronic actuators on the steering gear, it provides intelligent front wheel steering (iFWS). Schaeffler will also be showcasing its intelligent mechatronic rear wheel steering system (iRWS), which is an extremely lightweight solution, weighing no more than eight kilograms, and delivers enhanced safety and ride comfort.

Rolling chassis: technologies for new mobility solutions

The showcase will also include Schaeffler’s rolling chassis, a modular, scalable vehicle platform that enables new, driverless mobility solutions for passenger and freight transport as well as for specialized applications, such as cleaning machines. The platform demonstrates Schaeffler’s wide range of mobility technologies. Its flexible architecture supports a broad array of steering and drive variants to suit customer requirements – everything from single electric axles in combination with central steering to implementations incorporating four Schaeffler corner modules. Schaeffler has further optimized its corner modules for scalability and readiness for volume production. Each one allows a steering angle of up to 90 degrees and comprises a wheel hub motor, a wheel suspension system incorporating air suspension that enables the vehicle to “kneel” for greater ease of access, an actuator for electromechanical steering, and a brake mechanism.