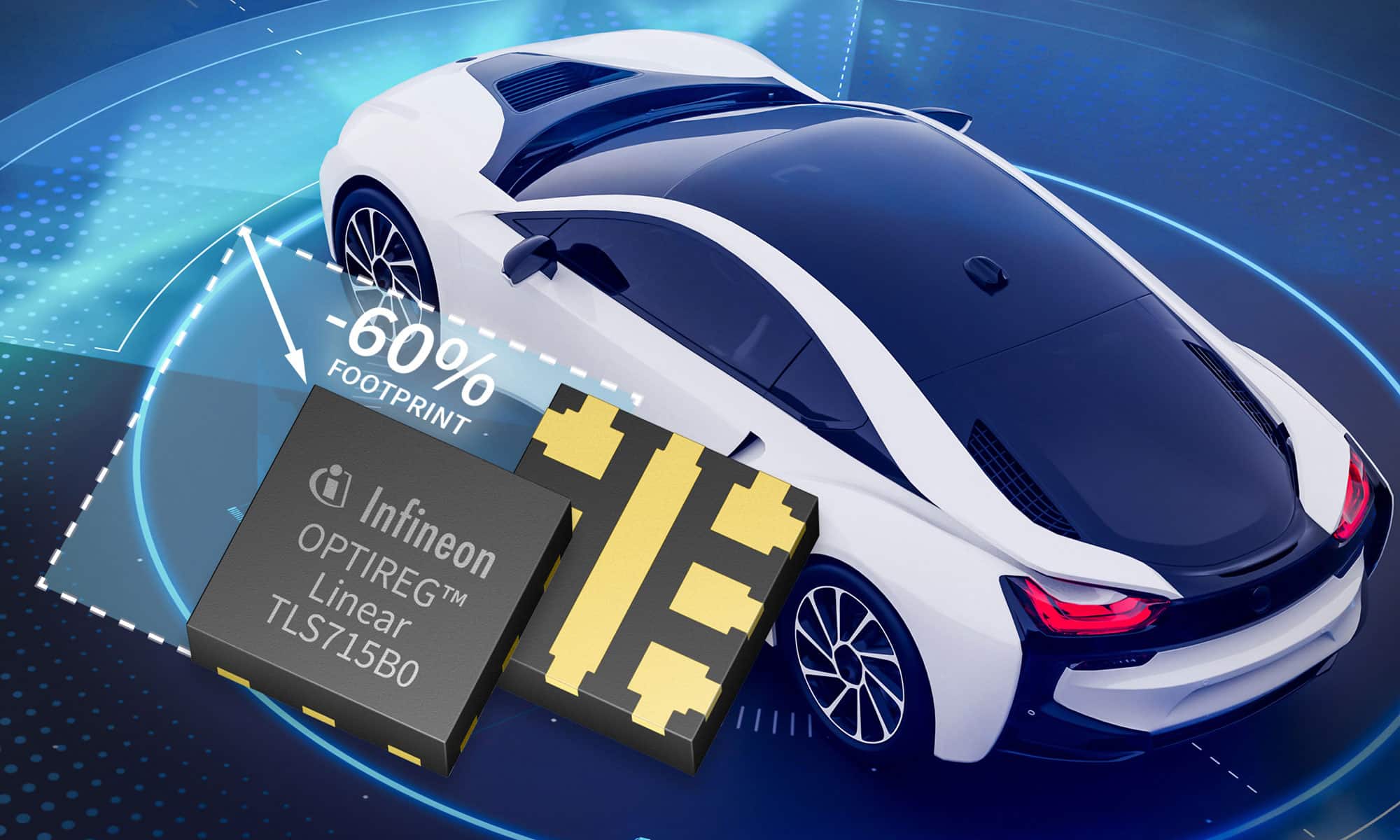

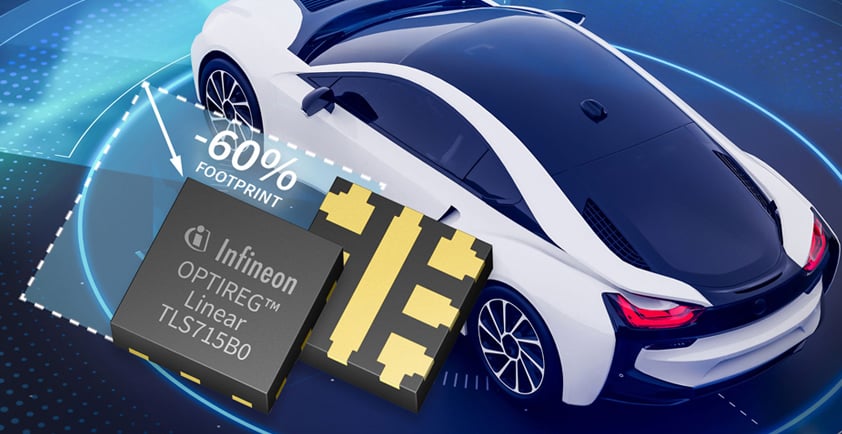

MINIATURE POWER SUPPLY: INFINEON STARTS FIRST FLIP-CHIP PRODUCTION SPECIFICALLY DESIGNED FOR AUTOMOTIVE APPLICATIONS

Munich, Germany – Infineon Technologies AG is taking the next step towards smallest power supply devices for automotive electronics. As first chipmaker, the company set up a dedicated production process for flip-chip packages that is fully aligned with the high quality requirements of the automotive market. Infineon now launches the first respective product: the linear voltage regulator OPTIREG™ TLS715B0NAV50.

With flip-chip technology, the ICs are installed upside down in the package. With the heated part of the IC facing the bottom of the package and being closer to the PCB, thermal conductivity can be improved by a factor between 2 and 3. The higher power density enables a significantly smaller footprint than conventional package technologies.

The footprint of Infineon's new linear voltage regulator (TSNP-7-8 package, 2.0 mm x 2.0 mm) is more than 60 percent smaller than that of an established reference product (TSON-10 package, 3.3 mm x 3.3 mm) while the thermal resistance stays the same. This makes the new device particularly suitable for applications with very limited board space, such as radar and cameras. The OPTIREG TLS715B0NAV50 provides 5 V with a maximum output current capability of 150 mA.

Flip-chip technology has been used in consumer and industrial markets for several years. Due to increasingly strict space requirements, particularly in the growing number of radar and camera systems, also automotive electronics require smaller power supply solutions – albeit with much higher quality requirements. In order to offer best-in-class flip-chip quality Infineon does not rely on a subsequent qualification of existing consumer and industrial products but rather on a dedicated production process for automotive devices.

In the future, flip-chip technology will strengthen Infineon’s overall portfolio of automotive power supply products in the OPTIREG family. The chipmaker is planning to apply it also to its switch mode voltage regulators and power management ICs.

SAFETY IN CARS: INFINEON’S AURIX™ IS THE FIRST EMBEDDED SAFETY CONTROLLER WORLDWIDE TO BE ASIL-D CERTIFIED ACCORDING TO ISO 26262:2018

Munich, Germany – Electro-mobility, advanced driver assistance systems, connected driving – the demand for functionally safe electrical and electronic systems in cars is increasing. Infineon Technologies AG has now reached a significant milestone: Its second generation AURIX™ (TC3xx) microcontrollers are the first embedded safety controllers worldwide to be certified for the highest automotive safety integrity level (ASIL D) according to the latest version of the ISO 26262 standard. This standard describes a globally binding procedure for the development and production of safety-critical systems in cars. In December 2018, the current version of the standard replaced the original version from 2011. The certificate was issued by SGS TUEV Saar.

“This certification underpins our leadership in automotive safety,” said Peter Schaefer, Vice President and General Manager Automotive Microcontrollers at Infineon. “We defined the safety architecture of our second generation AURIX microcontrollers before the new version of ISO 26262 was even available, and yet it fulfills all requirements for an ASIL D safety controller. We have achieved this through a holistic approach to safety that resulted in a sophisticated and robust architecture. Second generation AURIX microcontrollers thus provide the safety and trust necessary to make automated driving happen.”

The AURIX family has always been successful in safety-relevant applications. Leading computing platforms for automated driving rely on AURIX as their safety host controller. This includes, for example, the Qualcomm® Snapdragon Ride™ Platform from Qualcomm Technologies, Inc., a subsidiary of Qualcomm Incorporated, which was introduced at the Consumer Electronics Show in Las Vegas earlier this year. Furthermore, the microcontrollers are used in radar systems for processing sensor data, in engine and transmission control, brake, airbag and steering systems, central gateways, domain control units, hybrid and electric cars and many other applications.

In addition to the automotive sector, the product family is also increasingly used for other safety-critical applications, for example in commercial vehicles and robotics. Therefore, in the next step Infineon is planning certification according to IEC 61508. This is a cross-industry basic functional safety standard that serves as the foundation for application-specific standards.

AURIX TC3xx devices have up to six processor cores with 300 MHz clock frequency each. Up to four of them have an additional Lockstep core. With around 3,000 DMIPS, AURIX sets the bar for functionally safe computing power supporting ASIL D among safety microcontrollers. Other features include safe internal communication buses and a distributed memory protection system. Furthermore, AURIX allows the integration of software with different safety levels from different sources. This allows multiple operating systems and applications, such as steering, braking, airbag and driver assistance systems, to be hosted on a common platform.

Infineon has now launched sales of the AURIX TC3xx family for a broad customer and application base in the distribution market. To ease implementation for customers, the company offers extensive hardware and software support. In addition to starter kits and evaluation boards, a range of application kits are available. Infineon offers a free toolkit for software development and testing called AURIX Development Studio. In the AURIX forum, developers can discuss their questions with each other.

INFINEON ANNOUNCES NEW MICROCONTROLLER OPTIMIZED FOR AUTOMOTIVE 77 GHZ RADAR APPLICATIONS

Munich, Germany – Infineon Technologies AG will add a new member to its automotive microcontroller family AURIX™. TC3A will address new automotive 77 GHz radar applications such as high-end corner radar systems for advanced driver assistance systems and automated driving. New features include a new signal processing unit, a large SRAM memory dedicated to radar and four TriCore™ processors running at 300 MHz with two additional lockstep cores.

TC3A’s signal processing unit, called the SPU 2.0, is an evolution of Infineon’s accelerator for radar processing with reduced latencies for Fast Fourier Transform (FFT) processing, extended capability for intereference mitigation and different modulation schemes allowing first-tier customers to improve radar resolution at lower cost.

“The adoption of advanced driver assistance systems is growing and, eventually, they will evolve into automated driving. Cars in the future will be equipped with a lot more radar units to enable them to perceive their surrounding accurately,” said Ritesh Tyagi, head of the Infineon Automotive Silicon Valley Innovation Center. “The TC3A will enable Infineon to work with start-ups, industry leaders, and tech giants to accelerate innovations for radar systems.”

With its TC39, TC35 and TC33 AURIX devices Infineon already offers a set of microcontrollers for long-range, mid-range and short-range radar application. Each device has specific features enabling customers to address their different needs with performance and cost-optimized microcontrollers. The new TC3A will extend this portfolio at the upper performance end.

Key features of the TC3A:

> Four cores with TriCore architecture with two lockstep cores running at 300 MHz providing safe processing capability

> SPU 2.0 with extended features for realtime interference mitigation and lower resources consumption

> 6 MB of embedded SRAM to store data during processing

> High-speed radar MMIC (Monolithic Microwave Integrated Circuit) interface with up to 600 Mbps

> Hardware Security Module (HSM) compliant with EVITA full specification