CHASING THE NEXT WIN: RED BULL RACING HONDA PUSHES DATA TO THE LIMIT

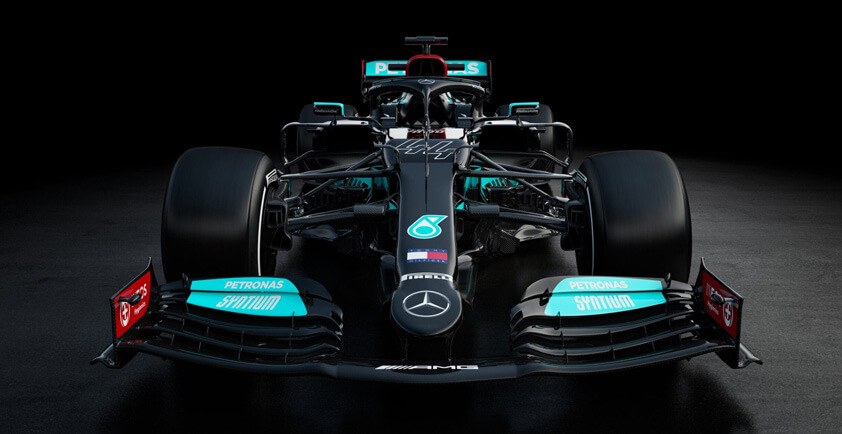

In Formula One, it’s not just the cars running at maximum speed. Hundreds of people, dozens of applications, and thousands of data points come together to achieve faster, better results, down to fractions of a second. The 2021 season features 23 races, each with the chance to use data specific insights to create a winning vehicle and on-track success. With an agile, efficient platform, the Red Bull Racing Honda team gains a competitive edge.

"For me, the perfect lap doesn’t exist. When we start looking into the data, there are always things you can improve." Red Bull Racing Honda driver Max Verstappen is fully immersed with pushing his car to the limit at each Formula One race track. He knows one insight-driven decision could be the difference between winning or losing a race.

Driven by technicians and engineers, powered by IT, and fueled by data, the race to develop the next car iteration happens off track. "It’s 750 people working towards one goal. And that goal is winning," says Verstappen. The team has just days between races to make changes that can shave vital milliseconds off the car’s performance.

"We’re a data-driven business and that data is our lifeblood in terms of how we develop and optimize these cars," states Red Bull Racing Honda Team Principal, Christian Horner. "You only see our shop window at each Grand Prix, but you don’t see what goes on behind the scenes with the technology that we’re using and the boundaries that we’re pushing."

A custom car, every race weekend

"Each circuit is different. It has its own challenges and its own characteristics: whether it’s the type of corner, or the altitude that it’s at. The car is bespoke to each circuit that we visit," explains Horner. "Up to a thousand components could change from one race to the next."

Between races, the clock is ticking to create new designs and adapt the car. Throughout an entire season, an F1 car can go through around 30,000 changes and, from week-to-week, this can involve 1,000 design elements. Every change in the process needs to be simulated, manufactured, and tested.

"Let’s say it’s a new front wing for the next race. There are many hours of compute resource and lots of brain power going into making sure that design is the best it can possibly be," Zoe Chilton, Head of Strategic Partnerships, describes what it takes to develop winning cars at Red Bull‘s Technology Campus in Milton Keynes.

The competition on efficiency

Formula 1 released new regulations for its 2021 season, focused on controlling costs. "New financial and resource regulations for the 2021 season mean that whilst the team continues to innovate and push boundaries, we need to be very smart when it comes to the efficient use of resources, including how we get the most out of the IT estate that underpins car design and development processes," explains Matt Cadieux Red Bull Racing Honda CIO

Another change in F1 rules limits how many aerodynamics testing hours each team can run per week, using a sliding scale based on last season’s performance. As one of the top scorers, Red Bull Racing Honda will have less wind tunnel and computational fluid dynamics (CFD) time than most teams. Not a second can be wasted, and peak application performance is crucial.

To achieve maximum efficiency and performance on its digital platform, the team partners with HPE. "We have a partner who understands our sport," notes Chilton. "They are willing to work to help us improve our performance and deliver those results more quickly."

We’re a data-driven business and that data is our lifeblood in terms of how we develop and optimize these cars." – CHRISTIAN HORNER, TEAM PRINCIPAL, RED BULL RACING HONDA

Design iteration, business iteration

Chris Middleton, Head of IT Infrastructure Operations at Red Bull Racing Honda, understands IT moves at the speed of the sport. "The car changes every race, our software changes every race, and as a result our infrastructure has to change every race," he says. That’s why the team relies on a software-defined, composable platform, based on HPE SimpliVity and HPE Synergy. "We can bring new apps into play. We can bring new VMs, storage, networking. All of that can be added or removed, saving massive amounts of time."

Agility is crucial. Supporting the complex Computational Fluid Dynamics (CFD) process, which underpins the aerodynamic development of the car throughout the season, virtualized Citrix workspaces run on HPE SimpliVity. This eliminates the need to switch between workstations to cross-analyze data on applications that run on different operating systems. This enables engineers to work faster and produce more design iterations. HPE Synergy with HPE OneView allows to quickly re-allocate compute or storage resources where required, enabling the team to meet changing needs and maximize IT usage.

These platforms’ high density also supports Red Bull Racing Honda’s quest for efficiency, saving money with reduced power, cooling, and footprint costs.

A non-stop team

With this approach, the team can adapt quickly adapt to changes beyond the car and racing circuit. "About 80% of our day-to-day business applications are running on HPE SimpliVity," relates Chilton. When the pandemic hit, the platform was ready to respond. "When we started redirecting people just before the Formula One shutdown, the infrastructure was so scalable and agile that we were able support more virtual users, more VDIs, and enable people to work from home. We could carry on without too much disruption."

Throughout the entire car development process, downtime is never an option. "If we can’t manufacture the next component in time, all the previous work will be wasted," Chilton says. The team’s need for reliable, highly available IT drove the deployment of HPE InfoSight, which delivers AI-enabled predictive analytics to prevent issues, as well as HPE Primera for tier one storage, a solution that guarantees 100% availability.

Crunching aerodynamics testing time

As the team evaluates car optimization, aerodynamics is a key component. Since regulations establish a time limit, the platform behind these processes requires the highest possible performance.

The first step is CFD simulations, which model airflow over the car, testing how different design elements can make it faster. This involves compute-intensive workloads such as physics simulations and 3D imaging.

"CFD models underpin the speed of design development at Red Bull Racing Honda. CFD produces complex 3D, graphically intense models and therefore the team needs significant and efficient compute power to derive the best outcomes," explains Cadieux. "These workloads run on HPE Apollo 2000 and HPE Moonshot, a high performance computing cluster that provides the scale, speed, and efficiency the team requires to maximize CFD in a costeffective manner."

Then, data from CFD simulations is confirmed at the team’s wind tunnel located in Bedford, where HPE Synergy provides compute for mixed workloads. Models built to 60% scale are tested to choose the best design before going into manufacture.

Every second is optimized to gain valuable data, captured by a high-speed imaging system, which produces large files that need to be quickly stored.

These images, along with all the data produced at the wind tunnel facility are stored on HPE Nimble, which delivers sub 0.5 milliseconds I/O latency for read and write operations. Chilton shares: "We’re using HPE Nimble to help us keep up with that pace of data ingestion. It’s made a huge difference."

Track-side intelligence

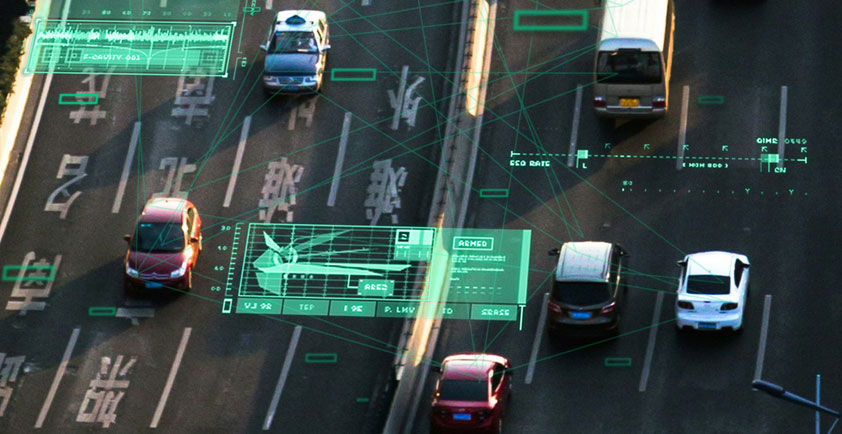

The accelerated design, testing, and manufacture process culminates at the circuit. "That race weekend, when we hit the circuit, that is our first chance to see at full scale how those components are going to perform. Is it going to be reflective of what we saw in our theory? That’s where the data comes face-to-face with the real world," says Chilton.

"We needed to be more agile and efficient at the edge with each race event," recalls Middleton. That’s why the team chose HPE SimpliVity as the core of the team’s mobile data center, where it provides post-processing of race telemetry data, as well as real-time insight to optimize car setup and support in-race decision making. The platform is ideal for trackside deployment because of it is compact, robust, and seamless to set up. "HPE SimpliVity impressed both in terms of performance and ease of management," relates Cadieux.

On race days, the team offloads data from a car in real time, then postprocesses it for analytics.

With HPE SimpliVity, the time required to crunch all the data has dropped 78%—from nine to two minutes. "It’s a massive increase in performance," says Cadieux. "What that means is we can get better answers quicker when we’re on the racetrack where seconds count."

Data shapes the next design

Back at the factory, the Vehicle Dynamics Group back receives data gathered at the track. "Sensors capture hundreds of data points across the car, every time it’s turning a wheel on track, or even when we fire the engine up in the garage. We’re always learning," Chilton describes. "Our engineers pull apart the data from that race in so much detail to help understand what we need to carry forward to the next race."

These datasets run on HPE Apollo 6500, which leverages faster interconnects for full utilization of GPU resources to enable faster, better decision making.

Partnering to the finish line

Throughout every step of the race, HPE provides a platform for the Red Bull Racing Honda team to make the car as fast as possible.

"Without having solutions from HPE, we can’t drive those processes: CFD, aerodynamics, vehicle dynamics, simulations," recounts Middleton. "Every thought process is aligned and we’re able to do great things,"

"Working with Hewlett Packard Enterprise is a hugely beneficial partnership for us. We’re able to be at the cutting edge of technology in a highly technical, highly stressed, environment," states Horner. "There is no bigger challenge than Formula One. It’s that marriage between creativity and data that has allowed us to achieve the success that we have over recent years."

The race starts again

The checkered flag drops. Another Grand Prix is over. But race the public will never see starts all over again. After every race, the car is stripped back to around 7,500 unique components. Each part is tracked and, if it didn’t perform optimally, the data is fed back to the R&D teams.

"It’s quite an extensive and aggressive process, but that’s what we hope gives us the edge on these turns," Chilton shares.

Then Max takes the wheel again: "Being in the car. Driving it on the limit. That is the best thing I do."