FROM SMART MANUFACTURING, TO SMART FACTORY—TO SMART ENTERPRISE

HIROTEC Group, one of the largest private production companies in today’s global automotive market, wanted to leverage Industry 4.0 innovations to tackle a perennial challenge: unplanned downtime. So it paired an IoT platform from HPE partner PTC with HPE Edgeline systems, boosting its already formidable operations technology capabilities with cutting-edge predictive analytics.

XHIROTEC Group: With 85 years of production and engineering experience, HIROTEC is globally recognized as a premier auto parts manufacturer and supplier.

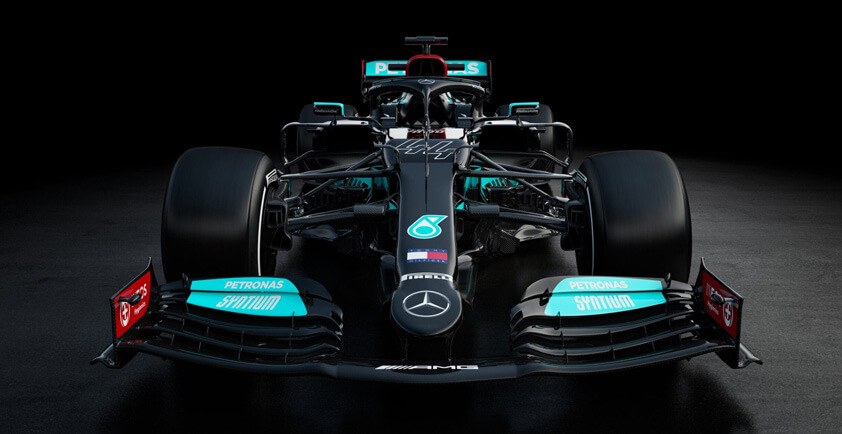

HIROTEC Group Companies is a $1.6B Japanese corporation that is globally recognized as a premier automotive manufacturing equipment and parts supplier. With over 85 years of mass production experience and engineering discipline, and 26 facilities in nine countries around the world, HIROTEC Group designs and builds roughly 7 million doors and 5 million exhaust systems a year, making it one of the largest private production companies in today’s global automotive market.

The most unwelcome domino effect: When you’re a key link in a global supply chain, unplanned downtime is a deal-breaker.

The auto parts Original Equipment Manufacturer (OEM) industry is crowded and competitive, with some 4,300 companies in the U.S. alone.1 Within this ecosystem, auto manufacturers are in an enviable position: they can pit suppliers against each other to keep prices low and quality high.

One of HIROTEC’s critical priorities, therefore, is to ensure continuous operations—and to minimize unplanned downtime in its manufacturing facilities. Not only is unplanned downtime costly, it also strikes at the core of HIROTEC’s promise to its customers: it puts the company at risk of falling behind on delivery timetables.

With the advent of Industry 4.0 manufacturing models, HIROTEC realized the time was right to leverage functionality like predictive analytics that promise to drive significant improvements to its manufacturing operations—improvements that could enable tremendous strides toward the ultimate goal of eliminating unplanned downtime entirely.

“According to industry benchmarks, in North America, the cost of unplanned downtime to automobile OEMs is $1.3M per hour. That’s $361 per second. If it takes a 3 minute phone call to report an issue, you can lose $70,000 just to tell someone you have a problem.”

JUSTIN HESTER

Senior Researcher – IoT Laboratory, HIROTEC Corporation

For today’s manufacturer, operations technology needs information technology

Adding IT capabilities to operations makes factories smart.

HIROTEC’s manufacturing teams have deep expertise in operations technology (OT)—expertise it has nurtured throughout its six-decade history. To realize the promise of Industry 4.0 technologies, however, its operations team needs to pair its OT expertise with IT skills and knowledge. And it needed to do this without diluting its resources or diverting focus from its core manufacturing priorities.

HIROTEC also needed an architecture built to eliminate data processing latency: it wanted the ability to leverage analysis in real time to control its factory machinery.

IoT cloud platform paired with edge analytics

The right technology partners pave the way to a tailored IoT solution.

HIROTEC’s first step was to find a partner to complement its Operations Technology skillset with IT capabilities. Its search led it to PTC, an HPE partner and provider of IoT and augmented reality solutions.

HIROTEC selected PTC’s ThingWorx Technology Platform, an enterprise cloud solution that supports rapid development and deployment of IoT software, and PTC’s KEPServerEX agent to support integrated device-to-cloud interoperability.

HIROTEC deployed the solution on an on premise cloud platform running on HPE ProLiant ML110 Gen9 Servers.

For its first pilot of the solution, HIROTEC deployed an on-site business-class server to support edge analytics, but the server was bulky and impractical.

So when it configured its second and third pilots of the IoT platform, HIROTEC selected HPE Edgeline systems to support edge analytics. The ruggedized HPE Edgeline systems small footprint minimized the need for HIROTEC to sacrifice valuable factory floor space. In addition, the systems do not require specialized cooling to operate.

Smart technology for a smart enterprise

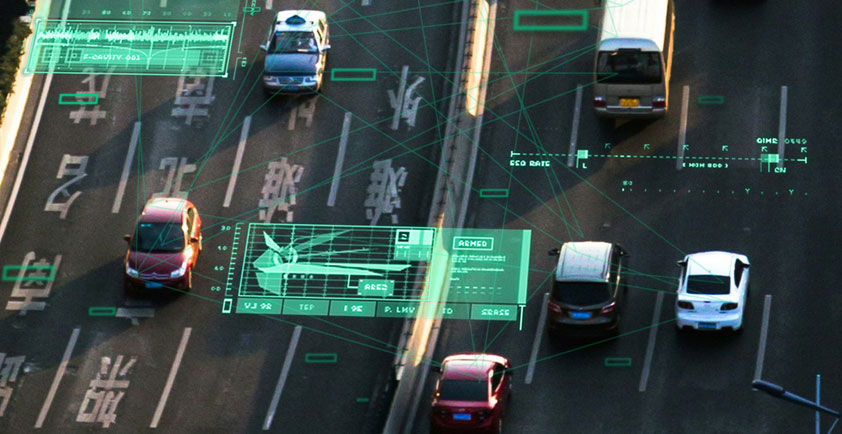

HIROTEC completed three pilots of the IoT platform. The first captured and analyzed data from eight Computer Numerical Control (CNC) machines in the company’s Detroit plant. Next, HIROTEC implemented the platform to perform remote visualization of an automated exhaust system inspection line. Data sources for this pilot included inspection robots, force sensors, laser measurement devices, and cameras. HIROTEC is deploying the system to perform real-time visualization and automatic, paperless report generation for the entire production line of an automobile door production facility.

Through the pilots, HIROTEC gained real-time visibility into its business operations, which in turn allows the company to address issues that impact its efficiency and throughput. The solution also equips HIROTEC to utilize machine learning functionality, which it will leverage to predict—and therefore prevent—failures in critical systems like robotic arms in its exhaust system testing line.

The solution also enables HIROTEC to perform sophisticated analysis of historical data so that it can better understand production facility performance and ways to drive improvements.

In the coming months, HIROTEC will build on the solution to enable augmented reality applications to further advance its manufacturing capabilities and efficiencies—completing its transformation from smart factory to smart enterprise.