DISCOVER THE LIFECYCLE OF A CONNECTED CAR

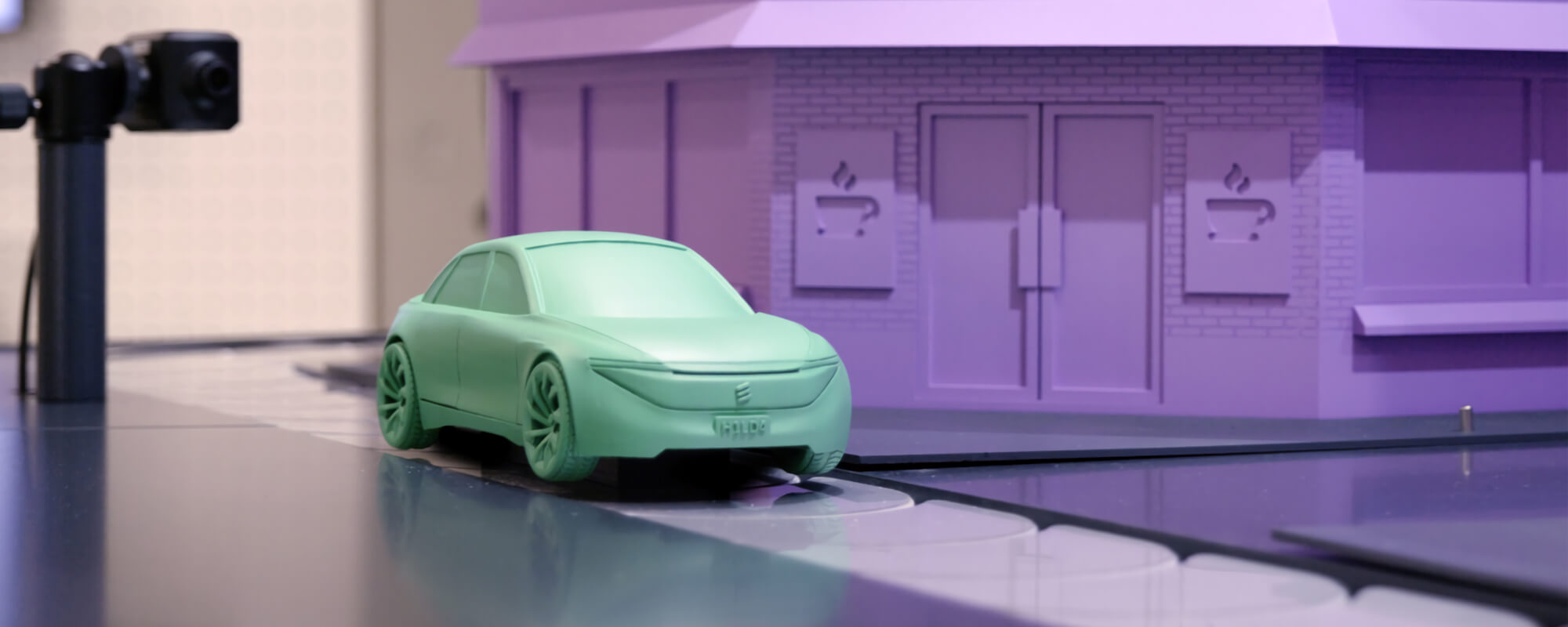

Meet Hilda, an Ericsson designed connected car. Hilda shows what is possible when cellular connectivity is adapted to all stages during the lifecycle of a connected car.

Almost every connected product follows the same lifecycle, birth at a factory, everyday use, to "rebirth" when it is recycled. The IoT lifecycle spans across several different cellular technologies; all aimed to solve specific challenges. How can cellular technology help automakers differentiate themselves on the market? And what additional business opportunities will 5G bring?

Age 0: Hilda – the connected car, building connectivity from the start

Meet Hilda, Ericsson's first in-house designed and connected car! Hilda exemplifies a connected car's connectivity requirements, from start to end. She shows the potential of bringing 5G business values to life during her lifecycle. The demands on connectivity and the opportunities it can unlock for both the manufacturer and the driver regularly change. To make connectivity seamless, it needs to be a core feature already embedded in the design phase for new models. Volvo Cars' newly released XC40 Recharge is a promising example of built-in connectivity as the car's core. The infotainment system is fully integrated with, e.g. Google Maps and Google Assistance. The driver does not have to use their smartphone to stay connected while driving. The car itself is the primary source of connectivity to apps and services and actively searches and updates when the car is on the road.

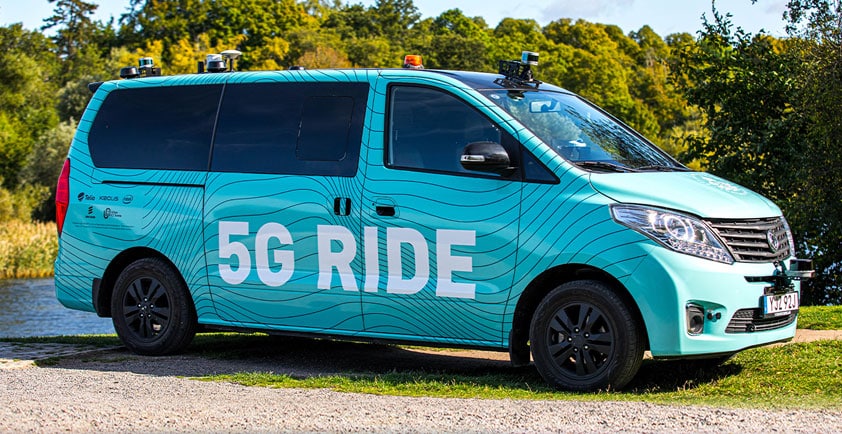

Connectivity can have a significant impact on an individual car, but the greatest business value is realized when connectivity fosters collaboration. When the full ecosystem (road infrastructure, traffic lights, and pedestrians) is interconnected and relevant data is shared, it leads to improved safety on our roads and enables further automatization of vehicles. Ericsson is a proud partner of the 5G Automotive Association (5GAA), that was created to connect the telecom industry and vehicle manufacturers. The purpose is to encourage stakeholders within the full ecosystem to collaborate to develop end-to-end solutions for future mobility and transportation services.

Connected vehicles today benefit from a large variety of 4G enables services (as telematics, infotainment, navigations, and fleet management). With 5G's low and controlled latency around the corner, combined with edge cloud deployments, there is the potential of taking these services to the next level in the years to come. "Today, we can do a lot with the 4G network, and looking forward, 5G will make it even better." (Håkan Eriksson, CTO, Telstra)

Age 1: Hilda is produced in the connected factory and has a digital twin

After R&D and product development, the next step in Hilda's lifecycle is production at the car factory. Smart and connected factories will enable cost-efficient production of connected cars. Ericsson works with several manufacturers and their digital transformation to Industry 4.0. Scania is testing cellular connectivity to connect the tools and equipment needed for truck manufacturing at their smart factory lab in Södertälje, Sweden.

A connected factory is enabled by several different 4G and 5G technologies along the production line, and we believe that 5G can change manufacturing as we know it. With intelligence being moved from the devices into the cloud, a digital copy of the factory floor and Hilda's so-called digital twin can help manage lifecycle stages. This includes supply, R&D, and transportation, to improve production performance and simplify tracking of assets. Since Hilda is designed with connectivity in mind, she also has a built-in connectivity module. This module can be transformed to meet connectivity requirements throughout the journey and potentially aggregate relevant data into one source. The connectivity module in the car can be used for tracking during the production phase and for logistics during transportation.

And the vision of a connected factory is not as farfetched as you might think. By leading through example, Ericsson actively works with automating its factories. The Ericsson factory in Nanjing combines cellular IoT and Industry 4.0 with excellent results. The factory recently celebrated its 1,000th cellular IoT device produced in the factory. The first year provided a 50% return on investment, and breakeven is projected to be reached in less than two years. Another example is Ericsson's first smart factory in the U.S. is now operational and produces 5G base stations to enable rapid 5G deployments. The factory is equipped with fast and secure 5G connectivity and will be one of the most advanced manufacturing facilities in the industry when it is fully operational later this year.

The requirements for lean manufacturing and concepts like the digital twin call for a fast, stable, secure, and simple connectivity solution. This is often achieved by different models of private and dedicated network solutions. It is extra thrilling to follow the newly built Factory 56 by Mercedez-Benz. Ericsson is teaming up with Telefónica Germany to enable car production via a private 5G network that will cover the 20000 square meter factory floor. And with a private 5G network, the intelligent connection of production systems and machines will be stable and secure.

Age 2: Hilda is transported and tracked through connected ports

When Hilda has been produced, she needs to be transported to her end destination. Since 90% of all goods globally pass through a port, Hilda will likely pass at least one along her route. Many of these facilities are starting to be connected and automated, enabling devices, machines, and humans to share real-time information. Several technologies and systems need to cooperate, such as networks and traffic towers. Dedicated networks are vital to support automated or even autonomous, fleet operations in closed areas, like mines or ports. A traffic tower enables humans to monitor, control, and remotely ensure that the automated operations run smoothly, even when something unexpected happens.

In 2019, Ericsson deployed and piloted 5G and Augmented Reality enhanced use cases in the port of Livorno, in Italy. This initiative was selected as best practice by the United Nations Sustainable Development Solutions Network and was presented at UN Global Goals Week 2019. The port illustrated how 5G connectivity improved the efficiency of loading and unloading operations. This resulted in an expected carbon dioxide (CO2e) reduction of almost 10% (8,2%) in this single port alone.

Age 3: Hilda meets the driver - global connectivity at the core of the vehicle

When Hilda is sold, her connectivity model is switched to operational mode. This includes activating connected services and subscriptions. Connected services today and in the future are more than just navigation and entertainment. It is also about services such as advanced driver assistance systems and software upgrades over the air. Drivers expect connectivity to work seamlessly whenever the car changes ownership or wherever they find themselves in the world.

This might sound easy; however, activation of IoT devices are still mostly carried out manually. And remember that a car is always in motion and is often crossing both country and regional borders while driving. The driver does not care how connectivity reaches the vehicle or by whom. It should just be as flawless as possible. To achieve seamless connectivity at a global level, there are a few different options available. Roaming between operators is one alternative. Another option is a localization setup where Hilda can switch operator and access local data plans through an eUICC solution (eSIM). Whatever the case, global connectivity is an essential requirement nowadays and can be solved through new types of collaboration within the telecom industry.

Hilda's future: meeting other Hildas, a connected driving ecosystem, and autonomous vehicles

Now Hilda is ready for the driver to get behind the wheel. Although self-driving cars are some way in the future, vehicles can already access assisted driver functionalities for both rural and city traffic.

Advanced driver assistance systems (ADAS) have features that help to reduce collisions and injuries on the road. To develop these functionalities, and move towards a more fully automated transport ecosystem, the key is for vehicles to communicate with its surroundings. The benefits grow exponentially when Hilda meets other Hildas (other connected cars). Hildas can share information with one another (V2V; vehicle-to-vehicle) as well as with everything around them (C-V2X; vehicle-to-everything). This is done by streaming data across the ecosystem of other connected vehicles and the local infrastructure, supported by a connected vehicle cloud solution, such as Ericsson Connected vehicle cloud. Collaboration between Hildas, over a cloud solution, can enable connected cars to see around corners digitally and to discover potential threats that are out of its line of sight. And Hildas can warn each other if there are dangers ahead.

Another Ericsson partner, Veoneer, provides cutting edge technologies for ADAS & Autonomous Driving (AD), with forward collision warning systems and lane change assistance. When these functions have split-second performance, are connected via the cloud to other vehicles and infrastructure along the roadway, these technologies can run at their full potential.

Ericsson has partnered with Telstra, Lexus Australia, and the local Victorian government to complete a unique, Australian-first C-V2X trial. The project leverages the existing cellular network to improve road safety. What we see here is the opportunity to improve road safety by providing information to drivers in milliseconds that they otherwise would not have received, so that we can get people home more safely.

Optimizing the Hilda connected experience with a network aware

Overall, it is a challenge for automotive manufacturers to provide a seamless experience for connected services. A network aware car like Hilda could be part of the solution. The vehicle can then predict connectivity levels and recommend actions to the driver proactively to solve the problems that might arise.

Hilda is also a software-defined vehicle and very similar to our smartphones, where Apple has set a high standard on user experience. Hilda is built on software, and her functionalities and capabilities can be updated and modified through upgrades comparable to upgrading the mobile phone's operating system. To enable an optimized, connected car during its full life cycle, one trend is to run software upgrades over the air (SOTA). The car can download new files and upgrade its software to a newer version without visiting the garage, which has been the norm up until today. The upgrade can also add features that were not previously installed to accommodate different driving situations. For instance, in a scenario where Hilda is driving in the forest, the car kicks up a bit of dust. What if Hilda could download a new feature to enable an off-road trail mode with more suspension?

Software Defined Cars (SDCs) will reimagine the way cars are built and sold and will offer the chance to upgrade a vehicle's functionality via SOTA updates. This gives Hilda the ability to adapt to the needs of drivers and fleet operators continually.

SOTA will, however, drive new demands on the cellular network and increase data volumes substantially. Connected vehicles, and especially driverless vehicles, require huge network capacity, low latency, and ultra-reliability to become a mainstream reality. 5G makes this possible for the first time, in combination with Edge computing, that provides one type of solution to manage high data rates and low latency requirements. This is particularly relevant for the auto industry due to the need to uplink large volumes of data to the cloud and to allow only accurate data to be collected.

An end and a new beginning for Hilda

Finally, at the end of life, Hilda needs to be recycled as much as possible. In a modern car, this includes IT components, metals, and physical materials. Recycling can be made more efficient when you know the history of the vehicle. Hilda can share data for a better understanding of how to manage components that are to be decommissioned, or preferable re-commissioned, to drive a smarter refurbish process.

As seen throughout the lifecycle of Hilda, the different phases are building blocks that rely on a holistic approach to connectivity. This approach allows Hilda to function as efficiently and optimal as possible.

In the design phase, it is critical to run both lab and field testing to secure that devices are well designed for connectivity. This is once again an example of how the industries come together. Sometimes the Telematics and Control Unit (TCU) manufacturer and car manufacturers are the same. Sometimes the TCU is sourced from an external vendor and adapted to the car.

Ericsson works with the whole supply chain, from the chipset makers to the end device as well as the automotive industry ecosystem. Hilda has an exciting lifecycle ahead, and Ericsson is all in.

Author - Linda Ålgårdh - Automotive Marketing Lead - Ericsson