AT&T BRINGS 5G TO FORD EV MANUFACTURING FACILITY

>> New connectivity paves the way for potential additional future advanced manufacturing technologies

Ford Motor Company and AT&T are enhancing the Rouge Electric Vehicle Center on Ford’s historic Dearborn Rouge site –the future of EV production – by outfitting it with highly secure, next-generation 5G cellular connectivity to help build the new all-electric Ford F-150 Lightning pickup.

Ford’s private 5G network based on AT&T 5G with AT&T’s Multi-Access Edge Computing (MEC) technology will support production of the 2022 Ford F-150 Lightning, the first all-electric version of America’s best-selling F-Series truck.

“With this collaboration, we’ll help Ford unlock the potential of 5G helping to build the truck of the future,” said Rasesh Patel, Chief Product & Platform Officer, AT&T Business. “It’s 5G connectivity coming to life! And it’s all thanks to the transformative ultra-fast speeds, incredibly low latency, and massive connectivity that is 5G in action.

“The Rouge Electric Vehicle Center was built with a clean-slate design and features the latest in advanced manufacturing technology,” said Adrian Price, executive director, Global Manufacturing Engineering, Ford Motor Company. “We are deploying 5G technology at this facility as a platform to enable us to use significant additional advanced manufacturing technologies in the future.”

The all-electric F-150 Lightning has a targeted EPA-estimated range of 300 miles, zero emissions and available Ford Intelligent Backup Power.

5G connectivity can help support the electric vehicle landscape by enabling future capabilities at the Rouge Electric Vehicle Center including the ability to:

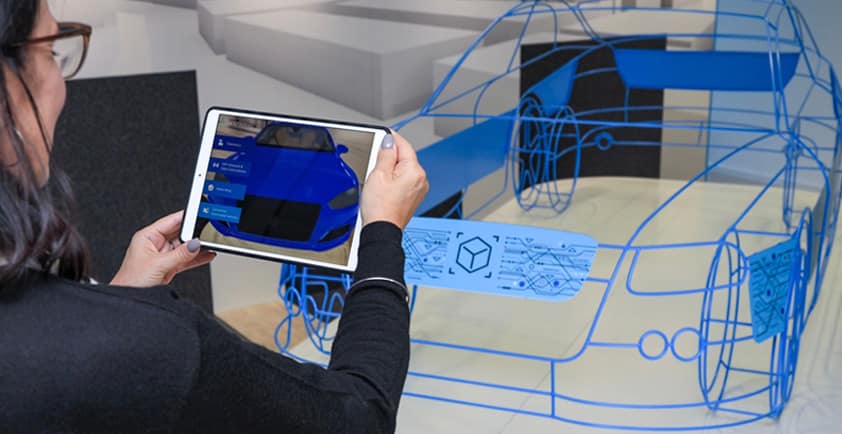

> Support New Technology – On the production line, employees use tablet computers to send and receive information about equipment status and material supply. Phones are also used as a vision system to scan specific components of the vehicle for accuracy. Both the phones and tablets will have 5G capability for faster processing times and better connection. 5G will support additional applications as the devices are updated to enable 5G connectivity.

>> Improve Automated Industrial Vehicles and Machinery – For any production facility, employee safety is the highest priority. The lower latency of 5G can help automated robotics and machinery make better decisions and faster reaction times to improve the safety of the workers around them.

> Enable Faster Wireless Vehicle Updates – Previously, vehicle software updates had to be made using mobile computing hardware, but now Ford makes these updates wirelessly. The 5G technology at the Rouge Electric Vehicle Center will provide a better connection for these updates, saving processing time.

Ford recently announced that it is investing an additional $250 million and adding 450 more jobs to boost production of the F-150 Lightning at the Rouge Electric Vehicle Center. Ford’s Rouge Electric Vehicle Center is in the historic Rouge complex, which sets the benchmark for sustainable automotive assembly. This new center supports Ford’s vision of sustainable production as a zero waste-to-landfill site. The Rouge Electric Vehicle Center uses natural lighting, as well as LED lighting and the primary forklift fleet uses hydrogen fuel cells with a zero-emission profile. It is built on the site of the old Dearborn Assembly Plant, using the former plant’s recycled foundation and construction materials.