WHAT IS AN ONBOARD CHARGER?

An onboard charger (OBC) is a power electronics device in electric vehicles (EVs) that converts AC power from external sources, such as residential outlets, to DC power to charge the vehicle’s battery pack.

The OBC communicates with the vehicle controller and charging station to determine the proper amount of current/power and the correct charging standard to be applied. There are multiple charging standards globally, including regional standards for Europe, North America and China. The OBC is able to automatically adjust to the correct regional standards based on data received from the EV supply equipment (EVSE) controller or vehicle controller.

The onboard charger also plays an essential role in bidirectional charging modes, meaning it can also convert DC power from the high-voltage battery pack to AC power to support AC loads (V2L), grid power (V2G) and even other EVs.

Enabling faster AC charging

Innovations in OBCs can help EV manufacturers meet consumer demand for faster charging while minimizing battery degradation. AC chargers offer two types of charging: constant current and constant voltage. Constant current charges the battery faster, but it cannot charge the vehicle to its full state of charge; constant voltage, also known as trickle charge, is slower but provides more control and can charge the vehicle to its full capacity. To optimize speed, the OBC uses constant current at the beginning of the charging cycle and switches to constant voltage at the end.

There are two primary types of onboard chargers: single-phase and three-phase. The capacity of a standard single-phase OBC is 7.2 kW to 11 kW, while a three-phase OBC has a capacity of 22 kW. The capacity of the OBC is a key factor in determining the vehicle’s charging time.

The fastest charging option available to consumers is DC fast charging, which bypasses the OBC altogether to provide direct current straight to the battery. Standard DC charging stations have a capacity of 50 kW to 300 kW — more than six times the capacity of single-phase onboard chargers. However, AC charging is gentler on batteries, so the increased capacity that three-phase OBCs provide can help consumers get the most from AC charging while minimizing battery degradation.

A system-level solution

There are a number of safety mechanisms integrated into an onboard charger to protect the end user and achieve the functional safety that automotive applications require, such as shutting off power if the load exceeds operating limits, and creating a separation between external hardware and internal components to mitigate the risk of electrical failure. Ensuring a cybersecure connection is also essential, given that the OBC acts as a high-speed gateway for data to travel between the vehicle and the grid when the EVSE controller is integrated.

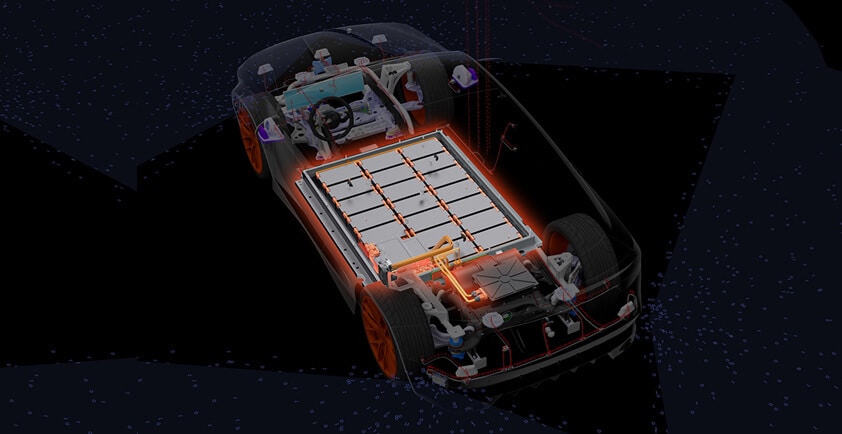

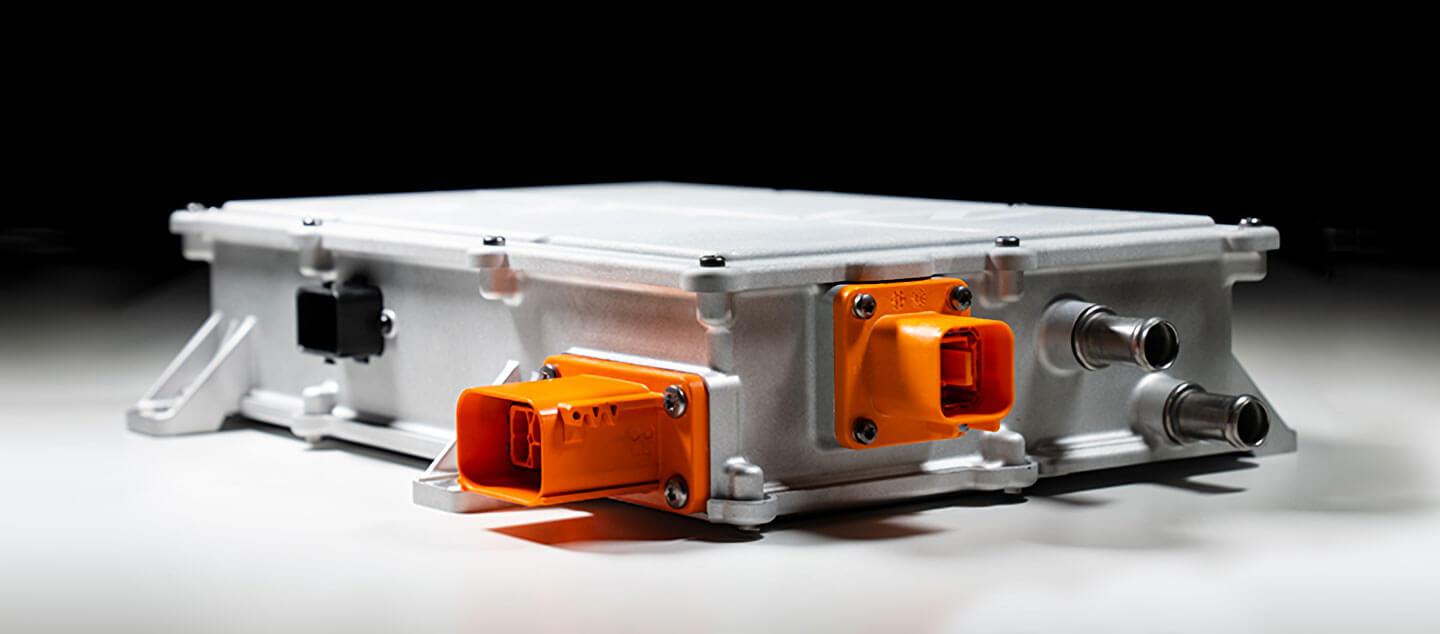

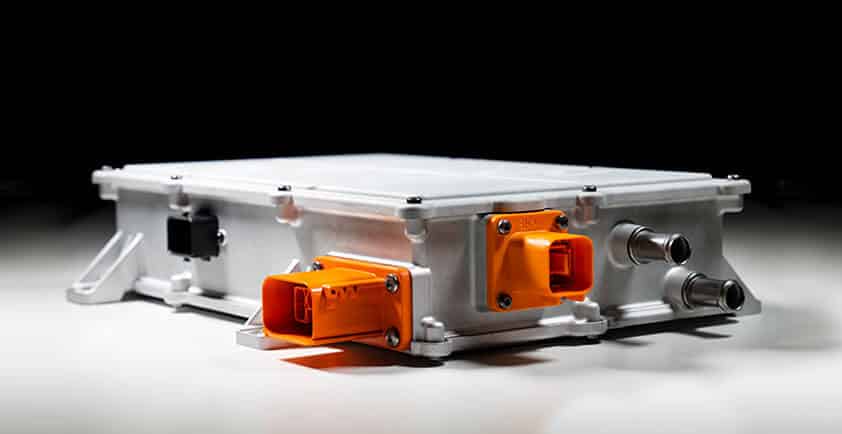

Aptiv’s high-voltage product offerings span from the inlet to the battery, including a three-phase onboard charger that is compliant with numerous automotive-grade data and charging standards, such as the ISO 26262 functional safety standard, the HomePlug standard, and the V2G standard.

Aptiv’s approach to optimizing electrical/electronic architecture is well suited to delivering cutting-edge integrated grid-to-battery-pack charging solutions that fulfill the highest requirements for performance, functional safety, cybersecurity and power.