AUDI’S AUTOMATED FACTORY MOVES CLOSER TO INDUSTRY 4.0 - CASE STUDY

Intel uses edge analytics and machine learning to help automaker enhance product quality

Executive Summary

With its Industrial Edge Insights software, Intel is taking analytics to the edge and helping German automaker Audi automate and enhance critical quality- control processes in its factories. Working closely with Audi engineers and technicians, Intel created a scalable, flexible platform solution that Audi can use as the foundation for current improvements and future innovations, enabling the company to increase effciency and reduce costs.

Accelerating product quality with digital technology

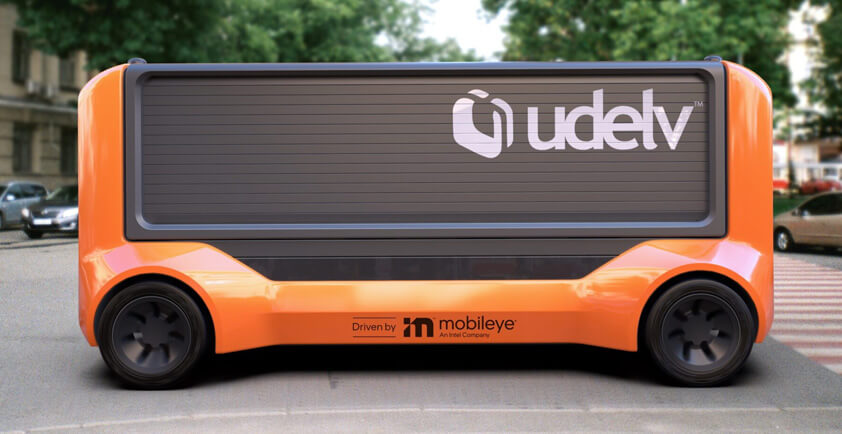

For Audi, a leading auto manufacturer and global brand based in Germany, the secret of success is building high-quality vehicles that deliver precision engineering, exceptional performance, and luxury at a price that customers nd attractive. Audi’s corporate slogan is Vorsprung durch Technik (“being ahead through technology”), which accurately reflects the company’s commitment to using cutting-edge technology to maintain a competitive advantage in the marketplace.

Audi has automated many production jobs in its factories, from spot welding to riveting, but its ultimate goal is to create smart factories and achieve an Industry 4.0 level of production. To accomplish that goal, the Audi engineers knew they would need to move beyond the traditional approach of creating customized hardware and software solutions to handle individual use cases. Instead, they would need a scalable and flexible platform that would allow them to embrace the transformative power of advanced digital capabilities such as data analytics, machine learning, and edge compute.

“If you look at factories today, Audi’s auto manufacturing operation is very advanced and extremely sophisticated,” says Christine Boles, Vice President of the Internet of Things Group and General Manager of the Industrial Solutions Division at Intel. “But custom-made use cases are difficult to maintain and scale, and they can actually hinder innovation because of the time and money required to get the necessary approvals and deploy individual solutions. Audi was ready to look at things in a new way and try a different approach.”

Proving the value of predictive quality control

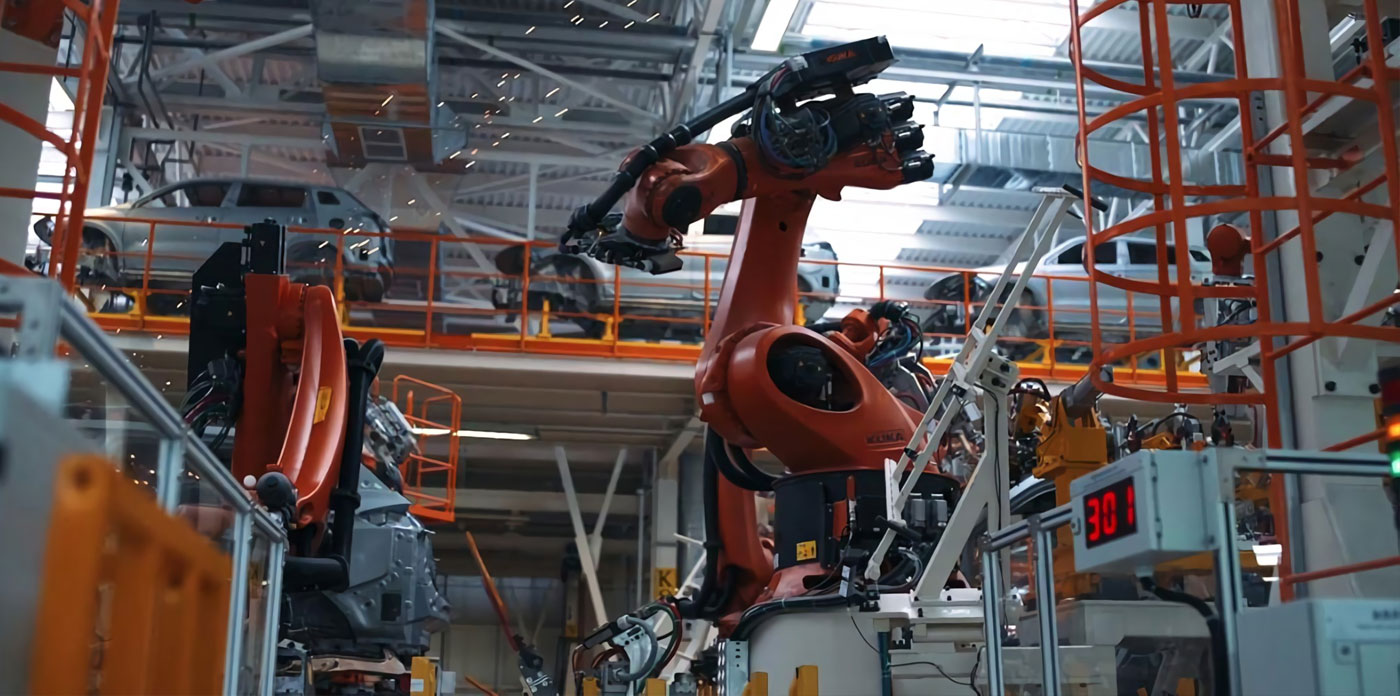

Audi decided to work with Intel on a proof of concept (POC) experiment focused on improving the quality-control process for the welds on its vehicles. The POC took place at Audi’s factory in Neckarsulm, Germany, one the company’s two principal assembly plants.

The Neckarsulm plant has 2,500 autonomous robots on its production line. Each robot is equipped with a tool of some kind, from glue guns to screwdrivers, and performs a specific task required to assemble an Audi automobile. Nine hundred of those robots carry welding guns to do spot welds that hold pieces of metal together. The production line is organized into a series of cells, and vehicles that are being assembled move down the line from cell to cell. Each cell can contain up to 20 robots and several milling machines. The milling machines are used to scrub clean the two electrodes on the welding guns, as needed, between operations. There are also three controllers outside the cell: one for the robot, one for the welding gun, and an Industrial PC (IPC).

Audi assembles up to approximately 1,000 vehicles every day at the Neckarsulm factory, and there are 5,000 welds in each car. That’s more than 5 million welds in a single day of production. To ensure the quality of its welds, Audi performs manual quality-control inspections. It is impossible to manually inspect 1,000 cars every day, however, so Audi uses the industry’s standard sampling method.

“Audi pulls one car o the line each day and takes it to a large room, where 18 engineers with clipboards use ultrasound probes to test the welding spots and record the quality of every spot,” says Rita Wouhaybi, Principal Engineer for the Internet of Things Group in the Industrial Solutions Division at Intel and lead architect for Intel’s Industrial Edge Insights software.

Sampling is costly and labor-intensive, and the process was leaving too many unanswered questions about the quality of the other 999 cars produced each day. Unfortunately, Audi had no feasible and cost-effective way to test the quality of those other welds. “Our big goal for this solution is to make it possible for us to inspect 100% of our welds with a very high degree of accuracy,” says Mathias Mayer, who leads automation technology planning at Audi. “Right now, we don’t have that kind of assurance. We inspect one finished car at the end of the production line. We have no in-line inspection process. Intel has both the technology and the expertise to help us improve our processes and achieve our goals.”

Creating a scalable analytics platform solution at the edge

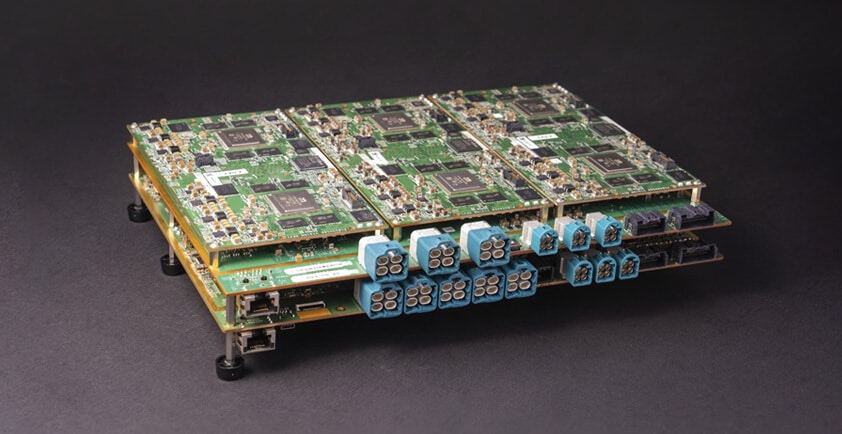

Intel worked with Audi to create algorithms using Intel’s Industrial Edge Insights software that resulted in predictive analytics and modeling to transform factory data into valuable insights. The solution ingests data from the welding- gun controllers, not the robot controllers, and analyzes it at the edge. Intel’s data scientists created a machine-learning algorithm and trained it for accuracy by comparing the predictions it generated to actual inspection data that Audi provided.

The machine learning model used data generated by the welding controllers, which showed electric voltage and current curves during the welding operation. The data also included other parameters such as configuration of the welds, the types of metal, and the health of the electrodes. This welding use case is just the beginning, however. Optimizations on the factory floor can go beyond one process to the rest of the factory. They can happen at the edge or at a higher level and identify correlations among processes. The power of providing an analytics platform at the edge is that it allows the control engineers and operators to innovate on top of their data.

The result is a scalable, flexible platform solution that Audi can use not only to improve quality control for spot welding, but also as the foundation for other use cases involving robots and controllers such as riveting, gluing and painting. A dashboard lets Audi employees visualize the data, and the system alerts technicians whenever it detects a faulty weld or a potential change in the configuration that could minimize or eliminate the faults altogether.

“Intel was the project leader,” Mathias Mayer says. “They have production experience as well as knowing how to set up a system that does statistical process control. This is completely new to us. Intel taught us how to understand the data, how to use the algorithms to analyze data at the edge, and how we can work with data in the future to improve our operations on the factory floor.”

“The value of putting the analytics platform at the edge is that it allows you to draw more data into it and look at correlations, causalities, and other interesting analytics— even some you might not think of at first,” says Brian McCarson, Vice President of the Internet of Things Group and Director of Industrial Systems Engineering and Architecture at Intel. “This platform gives Audi a lot of head room. It’s not just for this one use case. After making the initial platform investment, Audi can grow into it and scale it across facilities and to other use cases.”

Henning Löser, Senior Manager of the Audi Production Lab, agrees: “This solution is like a blueprint for future solutions. We have a lot of technologies in the factory, and this solution is a model we can use to create quality-inspection solutions for those other technologies so that we don’t have to rely on manual inspections.”

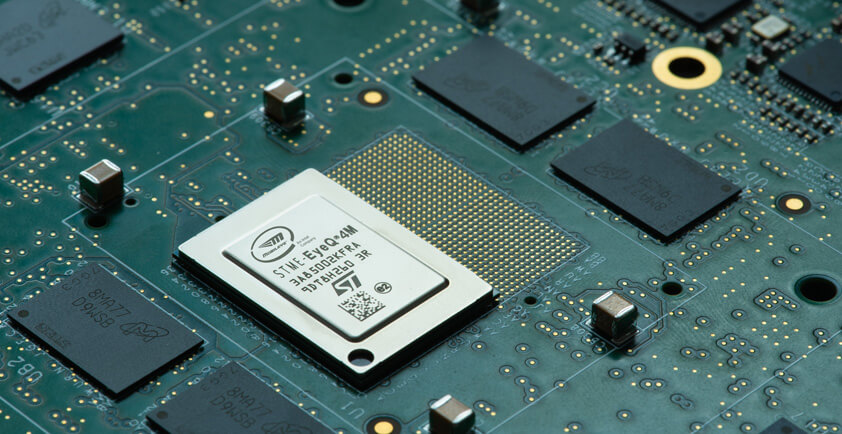

According to Christine Boles, the breadth of Intel’s product offerings was a key element in the solution. “We’re running this solution on a Xeon processor, but if you look at the Intel product line we can scale from our Intel® CoreTM processors all the way to our Intel® Xeon® processor E and Intel® Xeon® SP server processors with no changes to the software,” she says. “We can deliver all the performance and functionality a customer needs, and then easily scale in any direction, depending on what they want to do in their business.”

Increasing efficiency and precision while cutting costs

According to Henning Löser, the most compelling business outcome for Audi is how moving from manual inspections to an automated, data-driven process has allowed it to increase the scope and accuracy of its quality-control processes. But there are other bene ts that come along with that.

“At the Neckarsulm factory, we are already seeing a 30%- 50% reduction in labor costs,” says Michael Häffner, head of production planning, automation and digitization at Audi. Michael Häffner stresses that increasing automation and efficiency is not about replacing workers, but rather about giving them new knowledge and skills and creating new opportunities for them. It is also a necessity, because many skilled factory workers are retiring and taking valuable knowledge with them, so automating some of those jobs and channeling younger employees in new directions is good for the business and good for workers.

Another key bene t of the new system and the precise inspections it enables is that Audi can be proactive and focus on avoiding problems rather than merely reacting to them. “Let’s say we do an overall inspection of 5,000 or more welds on one car a day, and maybe 95% of those welds are good and 5% are not,” Mathias Mayer says. “In future, we can focus on the 5%, because we know where they are in the factory and we can take action much sooner.”

Looking to the future

Having a transparent system that lets them understand and learn from the data their equipment is generating is inspiring Audi to consider new possibilities and providing additional benefits—some of them unexpected. “Because of the analytics we are now running and the increased visibility of our data, Audi lowered its corporate tax bill,” Häffner says. “In the past, we had to make a lot of assumptions, and our taxes were based on those assumptions. Now, the real data shows that our tax obligation is less, which is a significant cost savings.”

Audi already has plans to use the platform for other use cases at the Neckarsulm factory, and eventually intends to deploy predictive welding inspection and other solutions across all Volkswagen Group production facilities. “We are at the very beginning of collecting and analyzing our data,” Henning Löser says. “As we continue this journey, there will be many more happy surprises and new opportunities for us.”