FACTORY OF THE FUTURE SHOWS MOBILE MODEL FOR SMALL MANUFACTURERS

Vodafone helps e.GO to radically reduce the cost and risk of electric car manufacturing

Professor Günther Schuh, who media sometimes characterise as Germany’s answer to Elon Musk, wants to create more affordable electric vehicles. My team has been working with him, designing a factory that helps to reduce the cost of getting more environmentally responsible vehicles to market.

e.GO

Günther’s company, e.GO was founded out of RWTH Aachen University in 2015 where he was vice-rector for Industry and Business Relations. By then he had already developed an electric delivery van, StreetScooter, a company that was bought by Deutsche Post in 2014.

300 e.GO employees currently work on the university’s campus while they develop a new assembly plant – due to open in 2020 - for the new e.GO Life 60 series.

Industry 4.0

E.GO challenged Vodafone and Ericsson to help them to develop an ‘industry 4.0’ factory that could help them gain a competitive advantage through the use of mobile technology. The result is a model that many other European companies might look to in future.

The 16,000m2 e.GO factory in Aachen is one of the first in the world to connect machines using a private ‘5G ready’ network rather than Wi-Fi. We installed 36 mobile antenna within the factory walls to connect all the machinery to the IT system and to send data back to the company’s network operations center, the factory’s brain.

Data is an important fuel for modern automotive production, so it is important that never leaves the production hall and the private mobile network ensures secure, encrypted communications. Mobile network slicing is being used for the first time in Germany to dedicate a slice of spectrum for the factory to ensure that critical manufacturing processes are never interrupted by inadvertent data packet loss.

The network edge

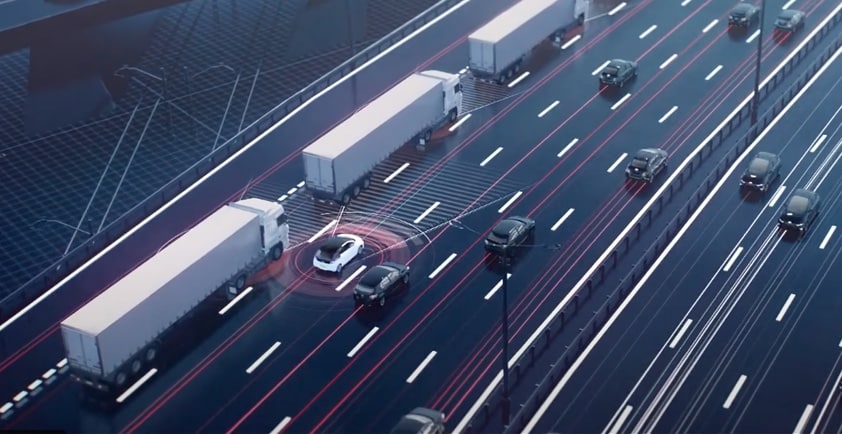

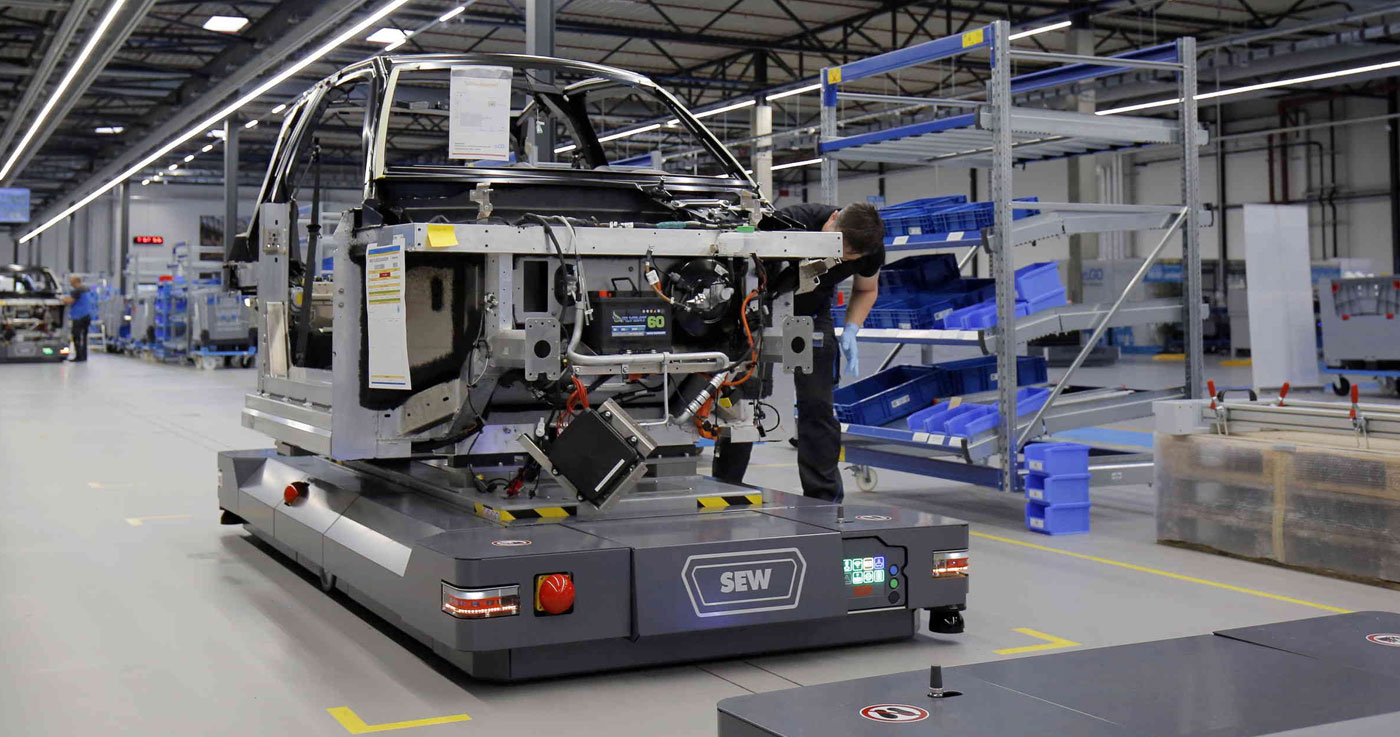

In another first for the company the network will use multi-access edge computing (MEC) to boost the processing power of the Automated Guided Vehicles (AGV) which carry the chassis from station to station, replacing the classic production line. The factory will contain the world’s first AGVs to use 4G+ rather than Wi-Fi.

These machines process environmental data, like unexpected objects in their path, near instantaneously (less than 10 milliseconds), ensuring both they and all other machines in the plant adapt their routines accordingly. In the future the AGV will be joined by smart forklifts and smart factory trains which will transport material between warehouses and production halls.

Maximum efficiency

An electronic database contains a digital twin of the factory: not only every component (tagged using radio frequency identification or RFID tags the moment they arrive) but also the exact specifications of how to assemble and disassemble components. Parts arrive at exactly when they are needed and the connected tools used by the human and robot workers automatically adjust to the exact level of torque needed for a task. This ensures future factories can be set up quickly and cost-effectively.

Adapting production

The use of mobile technology provides e.GO’s development team with incredible power to analyse network data and automatically adjust factory processes with the press of a button. When the team decided to move from a steel to an aluminum frame it took just three months to install new machinery and adjust processes, around a sixth of the time it would take a competitor to do the same.

The new e.GO electric car has taken just two years to develop, less than half the average time and has cost €70 million, four times less than the industry average development costs. While the current factory uses a 4G+ network, the amount of automation and the need for systems to process more and more data in real time will require 5G standalone in future, an upgrade e.GO is planning later this year.

The future of small scale production?

The e.GO Life assembly plant 1, is one of the first examples in the world of a true Industry 4.0 factory, with everything fully networked to an IT system. This has been an amazing project to work on and indicates how 5G and mobile technology can spur a wave of success for European businesses.

Author: David Rose, Senior Manager Digital Solutions, Vodafone Germany