U-BLOX: 5G WILL CONNECT THE INDUSTRY 4.0

Wireless communication is driving the next industrial revolution, with billions of machines, devices, and sensors just waiting to be connected. 5G is being designed with the industry’s needs in mind.

Industry 4.0, the Industrial Internet of Things (IIoT), the connected industry – call it what you may, one thing is undeniable: it is growing, and fast. According to IoT Analytics, the market for products targeting the connected industry is predicted to hit US$ 310 billion by 2023, with a CAGR of 37 percent from 2017 to 2023. In terms of market size, they expect advanced digital product development, data‑driven performance optimization, and predictive maintenance to be the leading use cases.

Wireless connectivity is one of the enabling technologies driving the transformation – in particular in smart manufacturing. That’s because it’s difficult to compete with the ease of installation and the short time and low costs required to upgrade existing systems. Because distributed wireless sensors are flexible and scalable and operate on trusted, secure networks, they are well suited to offer more and better quality information on every aspect of the manufacturing process.

A wireless patchwork

Of course, no single wireless technology will be able to serve the diverse needs of the industrial market. But as the ecosystem grows, those technologies that succeed in establishing themselves will serve fast‑growing use cases. We’re convinced that short range technologies such as Bluetooth (Bluetooth 5.0, Bluetooth low energy, and Bluetooth mesh) and Wi‑Fi will be among those to expand their reach into the connected industry.

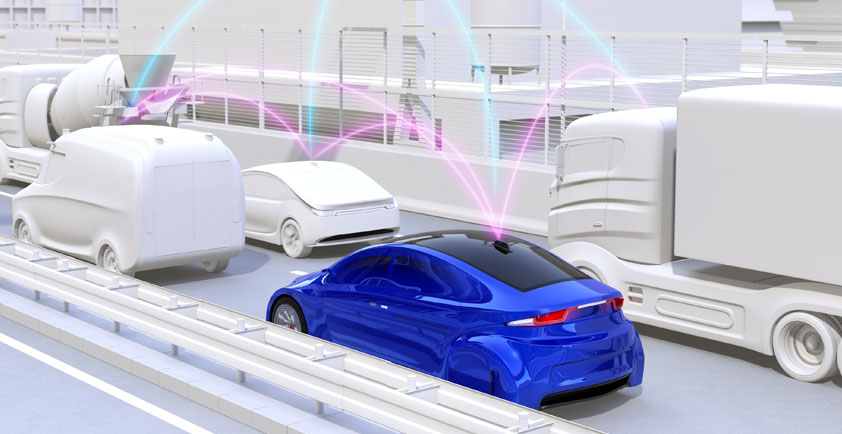

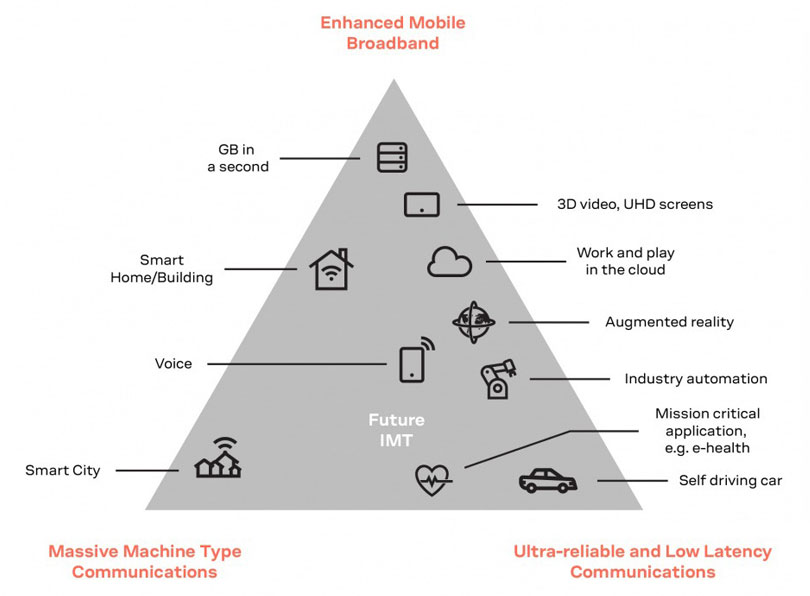

One of the major trends we see on the horizon is the convergence of the demands from Industry 4.0 and the ever evolving connectivity offered by 5G, the next generation of mobile communication technology. While previous generations of mobile network technology aimed primarily at increasing data rates, 5G is built on the three pillars – high data rates (enhanced Mobile Broadband – eMBB), high fidelity (Ultra Reliable and Low Latency Communication – URLLC), and high density (massive Machine Type Communication – mMTC).

Figure: Demands on 5G vary by use case, with industry automation on the right vertice of the triangle. (Adapted from ITU IMT‑2020)

Many emerging industrial applications lie at the intersection between two distinct pillars. Take mobile robots, which will require ultra‑reliable, low latency communication, but will also need to be connected to a high fidelity data pipe. The connectivity behind new Human Machine Interfaces (HMIs) that leverage augmented and virtual reality will need to satisfy the same demands to deliver high resolution images and respond in “real real‑time” to the user’s motions. Logistics applications will need to operate reliably in dense settings, such as in warehouses, with each individual sensor being able to coexist with hundreds, if not thousands, of others. And production automation will draw on all three vertices of the triangle, depending on the specific function being performed.

Private networks and data privacy

But what truly sets 5G apart from previous generations of cellular network technologies is that it gives the possibility for enterprises to set up unlicensed or licensed, non‑public 5G networks. In particular for companies that deal with highly sensitive information, having full control over their own communication infrastructure – and their data – will be a game changer.

Sure, it comes at a cost: companies will bear full responsibility over the quality and the performance of their networks. But, at the same time, it gives them unprecedented flexibility in tailoring their network’s security and privacy features to their specific needs. The 5G standard are helping to ensure that 5G‑compliant devices operate smoothly on the network.

Preparations for 5G are well underway

At u‑blox, we’re committed to being part of the process of shaping 5G standards to meet the needs of tomorrow’s industry. As member of the 5G Alliance for Connected Industries and Automation (5G‑ACIA), we are working together with the industrial partners in IT and OT to ensure that 5G technologies are fit‑for‑purpose for the connected industry. We’re participant in the EU‑funded 5G‑SMART project, aims to trial and validate connectivity technologies in real factory environments, from an Ericsson factory in Sweden, a Fraunhofer IPT shop floor in Germany, and a Bosch semiconductor factory in Germany.

But it isn’t all about tomorrow – the journey to 5G is already underway! Today’s low power wide area (LPWA) cellular technologies (LTE‑M and NB‑IoT) were designed to fit into future 5G networks. In other words, you don’t have to wait for 5G networks to fully roll out before you start building the technology into your industrial devices. Instead, get started today and take your first steps on the path to 5G.