DAIMLER: DESIGN FOR PROFITABILITY BY DEPLOYING SMART PRODUCT COSTING IN AN INTELLIGENT ENTERPRISE

Learn how Daimler, a world-renowned producer of luxury vehicles, deployed SAP Product Lifecycle Costing to help enhance the profitability of its iconic cars.

Daimler AG is the world’s largest manufacturer of commercial vehicles and one of the largest manufacturers of premium cars, complementing vehicle production, sales, and maintenance with global financing, leasing, and fleet management. To remain competitive, Daimler must post high results in all its key performance indicators. Prioritizing revenue growth, subsidiary Mercedes-Benz Cars recently deployed the SAP Product Lifecycle Costing solution to help calculate future product profitability.

Daimler Fuels Smart Design with SAP Product Lifecycle Costing

Before: Challenges and Opportunities

> Prepare for a highly competitive future by protecting profitability globally

> Improve costing efficiency to foster a focus on value-added design and development

> Integrate business and engineering and encourage collaboration across functions

Why SAP

> Costing solution that was co-innovated with more than 30 customers to boost usability

> Integration of the SAP Product Lifecycle Costing solution with multiple source structures and databases

> Process expertise from SAP, enabling the new system setup with minimal disruption in customized add-ons as needed

After: Value-Driven Results

> One consolidated landscape for costing all projects in the company’s Powertrain business unit and Mercedes-Benz Cars division to achieve a quantum leap in efficiency

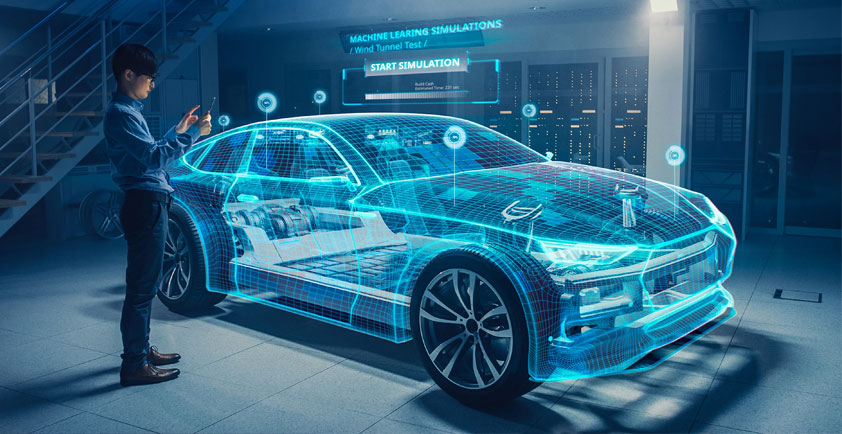

> Machine learning calculations and evaluation logic to increase agility in project costing and throughout the company’s new intelligent enterprise

> Rich analysis with engaging visualizations and high usability for 120 users company-wide

"Our implementation of SAP Product Lifecycle Costing let us set new high standardsfor project calculations enterprise-wide and helped enrich the SAP services portfolio with our joint lessons learned." Christoph Streuber, IT Manager and IT-Product Owner, Daimler AG

OBJECTIVES:

Implementing a Single Product-Costing Solution Across Mercedes-Benz Cars

To protect its profitabilityin the production of commercial vehicles and premium cars, Daimler AG recently launched an initiative to standardize product costing globally. The first step was the implementation of the SAP Product Lifecycle Costing solution across the Mercedes-Benz Cars division. In the company’s new intelligent enterprise, executives needed solid analysis in a single consolidated system on which to base product development choices.

Automating the configuration process - The company already knew that SAP Product Lifecycle Costing draws automatically from existing feeder systems and predefined rules to simplify the configuration of costing structures. Pricing is also automated, based on predefined strategies from SAP. And structures are highly flexible, encouraging innovation while maintaining standardization.

Promoting reusability and transparency - Daimler traditionally values the reusabilityof structures and modules to further increase costing efficiency. The cross-functional transparency in tightly integrated SAP software systems helps ensure easy comparison among separate costing efforts and interim calculations.

SOLUTION:

Augmenting the Standard Functionality

The pilot project at Mercedes-Benz Cars fueled Daimler’s ongoing evolution into an intelligent enterprise. And in addition to implementing the full functionality of SAP Product Lifecycle Costing, the project staff used engineered services and preconfigured add-ins to integrate customized features and analytics.

Streamlining bill of materials management - The standard product documentation function provided an option to upload bills of materials (BOMs), drawing prices from the purchasing function. And it automatically transferred data from the product modification plan and measure review system to BOMs. The project team added a mechanism to compare BOMs and identify differences between pairs of calculations.

Enriching analysis - To standardize processing across the division, the team automated rule-based mapping of structures in the company’s Powertrain business unit to BOMs in its Vehicle Products business unit. Costing engineers can customize the structures to examine further aspects of costing and harness a machine learning algorithm to refine their calculations.

Transferring knowledge - Experts from the SAP Digital Business Services organization helped promote adoption and productivity through knowledge transfer. They created a robust set of training documents and videos and published them on a project-specific help page. And they worked closely with local project staff to design a suite of new engineered services that can benefit other customers as well.

RESULTS:

Reaping the Benefits

The implementation of the SAP Product Lifecycle Costing solution at Mercedes-Benz Cars has brought the company numerous benefits that help simplify costing processes and preserve profitability.

Working faster and smarter - Establishing a single costing calculation across all business units has helped this intelligent enterprise slash product costs for new projects. Customization by means of add-ins has allowed the company to fold in various existing systems to harmonize business processes acrossfunctions and facilitate comprehensive analytics. Sophisticated visualizationshelp users at all levels quickly comprehend important data and trends. Streamlining the costing process has given costing engineers much more time to focus on strategic tasks in value-added design and development.

Enjoying a long-term collaborative partnership - Throughout the 12-month implementation, experts from Daimler and SAP worked as one team to integrate business and engineering functions in both companies. They explored and customized machine learning capabilities to help costing engineers prepare intelligent BOMs for products just entering design. And together, they created additional engineered services to improve the delivery of SAP Product Lifecycle Costing to customers and demonstrate ways to augment its already powerful functionality. Such co-innovation bodes well for future success at both companies.

FUTURE PLANS:

Combining Human Expertise with Self-Teaching Computer Algorithms

Daimler plans to scale its enterprise intelligence and protect its market share by adopting emerging machine learning innovations in SAP Product Lifecycle Costing. With these capabilities, a self-teaching computer algorithm helps define the costs of future products even when they are just ideas.

Reusing parts with known costs - When design first kicks off, many constituent materials have not yet been specified. Costing engineers can extrapolate from items used in existing products instead.

Finding the appropriate candidate part - When the costing engineer selects a part in an existing BOM, SAP Product Lifecycle Costing returns data on cost and frequency of occurrence.It also displays a rating determined by a machine earning algorithm that compares possible matches with expert human data to assign weights to various search criteria. If satisfied with the match, the engineer chooses the top-rated part, and the system adds it to the developing BOM and automatically recalculates the cost for the entire product.

Maximizing human-computer collaboration - If the machine learning match doesn’t satisfy the human costing expert, a simple slider mechanism lets them reprioritize criteria to fine-tune the search manually. With each pass, the solution helps the costing engineer discover price patterns and detect price anomalies. And in return, the algorithm uses the results of manual intervention to optimize its similarity metrics, also "learning" to make tighter matches the next time it runs.