RENAULT EWAYS ELECTROPOP: A HISTORIC ACCELERATION OF RENAULT GROUP’S EV STRATEGY TO OFFER COMPETITIVE, SUSTAINABLE & POPULAR ELECTRIC VEHICLES

Renault Group makes a historic acceleration in its EV strategy, leveraging its technological and industrial assets along with 10 years of experience in electric mobility to make bold choices and offer competitive, sustainable, and popular electric vehicles.

COMPETITIVE & SUSTAINABLE:

> The greenest mix in the European market in 2025, with over 65% of electric and electrified vehicles in the sales mix and up to 90% electric vehicles in the Renault brand mix in 2030.

> Renault ElectriCity: a compact, efficient, high-tech electric ecosystem in Northern France, combined with the Group’s e-powertrain MegaFactory in Normandy.

> A strategic partnership with Envision AESC to build a gigafactory in Douai to support the manufacture of latest technology, cost-competitive, low-carbon batteries from 2024.

> A joint project with the French start-up Verkor to codevelop a high-performance, locally sourced, and sustainable battery by 2022.

> A standardized cell footprint covering 100% of future BEV launches across all segments to reduce costs by 60% at pack level by 2030.

> A highly compact e-powertrain enabling -30% on costs and -45% on wasted energy, giving an extra EV range of up to 20km.

POPULAR & AFFORDABLE:

> A more balanced and more profitable product portfolio with 10 new electric vehicles.

> Two icons with Renault 5 costing 33% less compared to ZOE and another timeless revival with ‘4ever‘.

> A muscled-up all-electric C-segment with the All-new MéganE in 2022.

Renault Group expertise in generating added value throughout the battery lifecycle with

> Mobilize: up to 400 euros per year with V2G for EV drivers and a residual value of up to 500 euros per battery.

"Today is a historic acceleration of Renault Group’s EV strategy and for ‘made in Europe’. By building Renault ElectriCity, our compact, efficient, high-tech electric ecosystem in Northern France, together with our e-powertrain MegaFactory in Normandy, we are creating the conditions of our competitiveness at home. We’ll train, invest, and partner with established & emerging best-in-class actors in their fields including: STMicroelectronics, Whylot, LG Chem, Envision AESC, and Verkor. Ten new electric models will be conceived and up to one million electric vehicles will be manufactured by 2030, from cost-efficient urban vehicles to higher end sports cars. On top of efficiency, we are betting on iconic designs such as the beloved R5 to bring the Renault touch to electrification: making electric cars popular, said Luca de Meo, CEO of Renault Group".

Batteries: mastering NMC chemistry to produce one million units Alliance-wide by 2030

Leveraging its 10-year experience in the electric vehicle value chain, Renault Group’s battery strategy led to bold standardization choices within the Alliance to unleash competitiveness. With NMC based chemistry (Nickel, Manganese & Cobalt) and a unique cell footprint, the Group will cover 100% of the future BEV launches across all segments. It will cover all ranges with up to one million electric vehicles Alliance-wide by 2030. This chemistry choice delivers a very competitive ratio of cost per kilometer, with up to 20% more range compared to other chemistry solutions and a much better recycling performance.

At cell level, the Group will offer:

- As part of its EV strategy, Renault Group is partnering with Envision AESC which will develop a gigafactory in Douai with a capacity of 9 GWh in 2024 aiming at reaching 24 GWh by 2030. Close to Renault ElectriCity, Renault Group’s partner will produce latest technology, cost-competitive, low-carbon and safe batteries for electric models, including the future Renault 5.

- Renault Group has also signed a Memorandum of Understanding to become shareholder of the French start-up Verkor with a stake of over 20%. The two partners intend to co-develop a high-performance battery suitable for the C and higher segments of the Renault range, as well as for the Alpine models. The partnership includes the development of a pilot production line in France for battery cells and module prototyping from 2022. In a second step, starting from 2026, Verkor aims to build the first gigafactory for high performance batteries in France, with an initial capacity of 10 GWh for the Renault Group, potentially rising to 20 GWh by 2030.

In less than 10 years, the Group will drive its costs down step by step by 60% at pack level, with a target below 100 dollars/kWh in 2025, and even under 80 dollars/kWh while preparing the arrival of All Solid State Battery technology within the Alliance in 2030.

Powertrain: from sourcing to manufacturing in-house e-powertrain

Renault Group keeps one step ahead of competition by being the first OEM to develop its own e-motor – with no rare-earth (no-permanent magnets) and based on electrically excited synchronous motor (EESM) technology, along with its own reducer –. Having already done most of the investment, the Group has been able to cut the battery cost by two over the past ten years and will divide it by two again in the upcoming decade. The Group will gradually embed new technological improvements from 2024 on its EESM: stator hairpin, glued motor stack, brushless and hollow rotor shafts; lowering costs and improving the efficiency of the motor.

The Group has also signed a partnership with the French Start-up Whylot for an innovative automotive axial flux e-motor. This technology will first be applied on hybrid powertrains aiming to reduce the costs by 5% while saving up to 2.5g CO2 on WLTP (for B/C-segment passenger car). Renault Group will be the first OEM to produce axial flux e-motor on a large scale from 2025.

On Power Electronics, the Group will extend its value chain control by integrating the inverter, DC-DC and the onboard charger (OBC) into a unique box produced in-house. With a compact design, this One Box Project will be 800V compliant, with less parts to reduce the cost, and will be used across all platforms and powertrains (BEV, HEV, PHEV) for further scale effect. Power modules for inverter, DC-DC and OBC will rely respectively on silicon carbide (SiC) and Gallium Nitride (GaN) thanks to our strategic partnership signed with STMicroelectronics.

On top of these new technologies, the Group is also working on a more compact e-powertrain called the all-in-one system. This e-powertrain consists in integrating the e-motor, the reducer and the power electronics (One Box Project) in a single package: enabling -45% volume in total (equivalent to the volume of the current-generation Clio fuel tank), -30% cost of the overall powertrain (this saving in value being the equivalent of the e-motor cost), and -45% on wasted energy on WLTP giving an extra EV range of up to 20km.

EV-native platforms: delivering high efficiency & optimum range at competitive cost

With CMF-EV and CMF-BEV the Group capitalizes on its 10 years of EV experience making dedicated EV platforms.

For the C and D segment, the CMF-EV platform offers an enhanced driving pleasure with unparalleled performances. This platform will represent 700.000 units at the Alliance level by 2025. CMF-EV offers a range up to 580 km WLTP with very low energy consumption. This performance is the result of the deep knowledge of Renault Group’s and Nissan’s engineers working on reduced friction, weight reduction and a state-of-the-art thermal management.

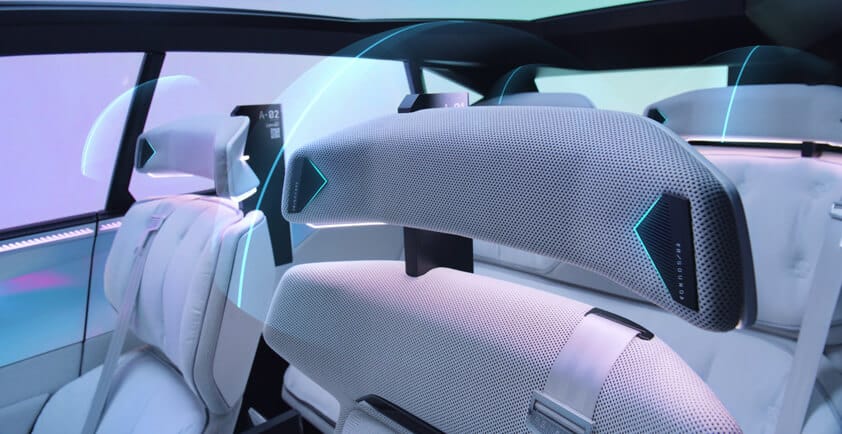

The architecture pushes the boundaries enabling greater roominess with all the technical elements in the engine bay and removes all crossing cables from the rear to the front and reduces weight and cost. The heating ventilation and air conditioning is also located in the engine bay, allowing a thinner dashboard design.

In addition to these enhancements CMF-EV offers great driving pleasure thanks to its low centre of gravity and ideal weight distribution, a very low steering ratio allowing quick vehicle response and a multi-link rear suspension. The All-new MéganE produced in Douai is based on the CMF-EV platform.

For the B-segment, CMF-BEV will allow the Renault Group to make affordable BEVs for everyone. This brand-new platform will reduce the vehicle cost by -33% compared to the current generation ZOE. This has been achieved with the interchangeability of the battery module, a right-sized powertrain of 100kW at lower cost, and all non-EV components caried-over from the CMF-B platform and its 3 million vehicles per year by 2025. CMF-BEV will be affordable with great performances offering up to 400km in WLTP, with no compromise on design, acoustics and driving behaviour. This platform will also feature the Group’s innovation Plug & Charge base on the NF-C 15118 regulation.

Operations: making competitive electric vehicles made in France

On June 9th, 2021, the Group announced the creation of Renault ElectriCity to offer cars “made in France”. This new legal entity in northern France gathers the three Renault plants of Douai, Maubeuge and Ruitz, as well as a strong ecosystem of supplier facilities. As early as 2024, it will be supplied with cost-competitive batteries by the gigafactory of Envision AESC in Douai. Ideally located, it is in the heart of European BEV demand, as France, United Kingdom, Germany, Italy, and Spain will represent around two thirds of the total in 2025.

Embodying a successful transition from traditional, internal-combustion engines into electric powertrains, this industrial ecosystem involves the creation of 700 new jobs by the end of 2024. Together with Envision AESC and Verkor, Renault Group will create 4,500 direct jobs in France by 2030.

Being the largest production centre dedicated to electric vehicles in Europe, this single entity enables Renault Group to make these plants the most competitive and efficient production unit for electric vehicles in Europe, with 400,000 vehicles produced per year by 2025 and production cost downsized to ~3% of the value of the vehicle.

Battery lifecycle: generating additional value throughout the lifecycle

Renault Group is the first carmaker to act on the entire life cycle of the battery. It has developed solid expertise and goes even further with Mobilize to increase their durability, extend their uses and generate additional value at each step of the lifecycle.

- During the first life of the battery in the vehicle, the Group is developing solutions for Vehicle-to-grid (also called V2G) that enable energy to be pushed back to the power grid from the battery of an electric car. Grid operators are very interested in these power storage solutions brought by car battery to balance load at all times. This way, a car connected 8 hours per day could generate a value potentially up to 400 euros per year through V2G, allowing EV drivers to offset part of their annual leasing cost and Renault to capture recurrent profits related to car fleets.

- At the end of their first life in the vehicle, batteries may still contain around two thirds of their capacity and can be reused for a second life. Mobilize is developing new applications around stationary battery storage to manage punctual power needs, mobile electricity storage or generators for use in other industries. Renault is pioneering this market and has defined a unique industrial setup to lead this market in Europe : the collection of end-of-life batteries with the support of its dealer network, the ability to appraise the fair value of batteries thanks to real-time technical monitoring, and the industrial capacity to refurbish batteries at competitive prices and repackage the upcoming 250 000 units of Zoe leased batteries.

Expanding the value chain, the Group plans to collaborate with car rating agencies so that the residual value of batteries is taken into account in used-car market transactions for a value up to 500 euros per car. To reassure owners of second-hand electric vehicles, Mobilize will offer ‘health certificate’ (for State Of Health monitoring), battery warranty extension contracts, and trade-in offers made possible by the connected vehicle.

- End-of-life: Through its subsidiary Indra and longstanding partnership with Veolia, the Group benefits from a robust know-how in EV battery collection and recycling. It has already recycled 75 MWh cumulated capacity in batteries half of which in 2020 only. Going even further, the Group is deploying retrofitting, battery re-using, dismantling and recycling facilities through its Re-Factory project in Flins with the objective to generate more than 1 billion euros of turnover from end-of-life and recycling activities by 2030. Going further in recycling, the consortium recently announced with Solvay and Veolia enables the recovering of strategic battery materials such as cobalt, nickel and lithium with a very high efficiency and battery-grade quality, so they can be reused in the production of new car batteries.

Evolutions in its overall battery collection and recycling process will allow Renault Group to divide the net cost of recycling by three by 2030, and secure an alternative and sustainable sourcing of battery materials at a competitive cost for part of its needs, while preserving these natural resources.

Line-up: Electro-pop cars

The Group will make the best out of its dedicated EV platforms, launching 10 new battery-electric vehicles by 2025, seven of them will be for the Renault brand. The iconic Renault 5 with a modern and electric twist will be made in Northern France, from battery to e-powertrain to assembly, on the brand-new CMF-BEV platform, by Renault ElectriCity.

The Group will also revive another magic, iconic star currently named ‘4ever’ signifying the intention to make it a timeless classic. Renault Group will also muscle-up on an all-electric C-segment, firstly with the All-new MéganE next year. On the avant-garde, the Alpine ’dream garage’ unveiled in January is coming true, starting in 2024.

The Renault brand aims to have the greenest mix in the European market in 2025, with over 65% of electric and electrified vehicles in the sales mix and up to 90% battery electric vehicles mix in 2030.