FASTER DATA, FASTER CAR: HOW BWT ALPINE F1 TEAM AIMS TO LEAD THE FORMULA 1 TECH RACE

Midway through the Dutch Grand Prix, radio traffic between 20 Formula 1 drivers and their busy crews buzzed with the usual chatter about lap times, tire conditions and pleas to "push now" – a frantic wall of sound rivaling the powerful engines roaring around the track.

But precisely 59 minutes and 27 seconds into that Sept. 4 race, one sentence from the comms chorus grabbed the attention of Matthieu Dubois, chief strategist for BWT Alpine F1 Team, based in Enstone, England and Viry-Châtillon in France. What Dubois detected was a simple instruction to Lando Norris, a driver with McLaren, Alpine’s top rival.

"Lando, both safety car windows are open, please confirm," the McLaren race engineer told Norris, who was leading both Alpine drivers at the time.

A large data display on BWT Alpine F1 Team’s pit wall instantly transcribed the McLaren engineer’s spoken words. Leveraging Microsoft Azure, Dubois had plucked that snippet from the radio din by simply typing the keyword "window." It would change the race for Alpine.

"That was crucial information," Dubois recalls. "McLaren was telling their driver that a safety car was on track (due to another car stopping). So, they were telling Norris to pit."

With that intel, Dubois instructed BWT Alpine F1 Team driver Fernando Alonso to also pit for fresh tires. His quick decision allowed Alpine to exploit a brief stretch when every car slowed for the caution period – and when Alpine’s top competitor was momentarily off the track.

Driving on the new tires, Alonso soon posted one of the day’s fastest laps (averaging 128 mph). Then, Alonso passed Norris, finishing sixth overall, and nosing out the McLaren driver by a mere half second. That result earned BWT Alpine F1 Team eight points in the Formula 1 standings, pushing Alpine further ahead in their season-long fight with McLaren.

"We gained position with the help of this information," Dubois says. "Data is probably most of our world now."

In Formula 1, every race week is jampacked with live data. Each team fields two cars that are essentially mobile IoT devices. The cars are equipped with a few hundred sensors that send a constant flow of telemetry back to the teams, revealing everything from engine temperature to brake wear, while collectively generating more than 600,000 numbers per second.

Still more data is produced at the teams’ technical centers as new car parts are manufactured and tested during the days leading up to the races. In total, Formula 1 teams gather as many as 50 billion data points each week.

In data processing terms, that’s a mighty big heap of bits and bytes. The trick is to unify those raging data streams into a single source of real-time insights that’s accessible across an entire organization.

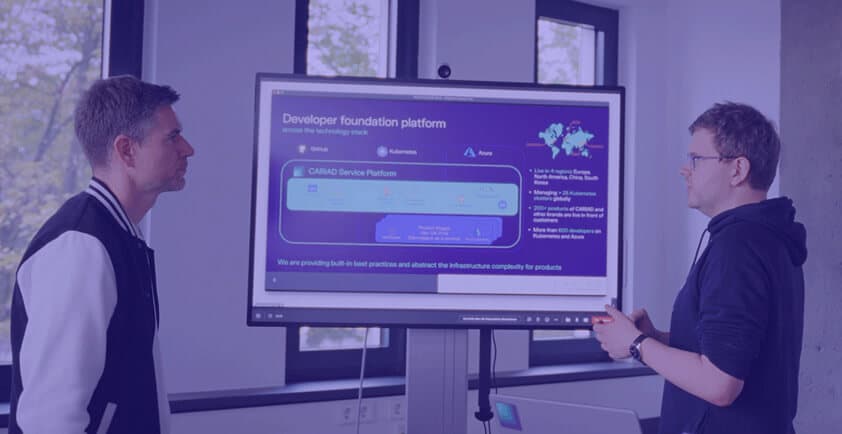

For the 2022 season, BWT Alpine F1 Team built a cloud-hosted, data science platform that relies on Azure infrastructure to deliver decisive insights from the team’s manufacturing and testing work and from its practice laps and race-day sprints.

The platform helps Alpine shape design decisions and make real-time race adjustments, team members say.

According to one more slice of data – Formula 1’s team standings – the technologies have helped boost BWT Alpine F1 Team during 2022. With one grand prix race remaining in the 2022 season – Nov. 20 in Abu Dhabi – Alpine has amassed enough points to reach fourth place, on pace for its highest finish since 2018. McLaren sits in fifth place.

"The entire organization is here solely to make the car go faster," says Pierre d’Imbleval, BWT Alpine F1 Team’s vice president of information systems and IT. "In our business what matters is always to get the information sooner and to shrink the time we have."

But the team’s cloud-based infrastructure also helps fuel smart and safe race strategies – tactics that require less velocity.

"We are so dependent on data," d’Imbleval says. "Almost every race, there is a moment of truth where you get a combination of data that tells you to slow down a bit to save the lifetime of your brakes or your engine.

"During races, we are so close to the failure point on certain parts that it’s super important to monitor all data at every moment."

It’s equally vital to monitor competitors’ radio traffic. But the BWT Alpine F1 Team crew no longer must physically listen to all that cross-communication – a public broadcast that’s piped into the paddock. Instead, they now merely glance at a large screen on their pit wall to read selected phrases uttered by the other teams.

To accomplish that, the Alpine staff fed audio files from past races into Azure to train a computer model that now delivers nearly real-time transcripts from every driver and race engineer.

This enables the Alpine crew to search for keywords, such as "tires overheating," allowing the team to quickly adjust their race strategy.

"We need to make decisions in fractions of seconds," says Sergio Rodriguez, BWT Alpine F1 Team’s data science and engineering manager.

Indeed, modern success in Formula 1 is not so much about big data as it is about fast data. And the need for speed is just as pressing at Alpine’s two manufacturing hubs as it is on the track.

The team designs and assembles its chassis at a facility in Enstone and builds its hybrid V6 engines at a technical center in Viry-Châtillon, a Paris suburb. Hundreds of engineers and mechanics work at each site, developing, testing and assembling new parts, many aimed at improving the cars’ aerodynamics or power.

The process is painstaking yet often performed at pace. The team creates computer-simulated models of new parts then calculates how those virtual prototypes would react to, say, drag or downforce, ultimately predicting how they would perform in a real-world race car.

"That involves big data clusters," Rodriguez says. "Once we say, ‘This looks good,’ we manufacture a small version of the part and put it in our wind tunnel. We pass wind through it. We check pressures. All this data we gather as well."

BWT Alpine F1 Team is relying on its cloud-hosted, data science platform to "unlock the information we have in the data," which saves precious time when pushing new parts from the factories to the cars, Rodriguez says.

"The work that we are doing in the factories this year is almost more important than the work we are doing (at the track) on the weekends," Rodriguez adds.

"Every Formula 1 team is building new parts and improved versions of their cars every weekend. But if you are able to bring out a new part one race before your competitor, that’s one race that you are going to be in front of him," he adds.

This season, BWT Alpine F1 Team accomplished that feat for the British Grand Prix. In Enstone, team engineers and mechanics worked nearly non-stop in the hours before the race to design and build a new floor.

"We had people in the factory over the weekend finishing the floor," Rodriguez says. "We were improving it overnight, then taking it back for Saturday testing, and then we brought it back to the track on Sunday. We managed to overtake McLaren thanks to this push from the factory."

At the British Grand Prix, Alonso finished fifth, 2.37 seconds ahead of McLaren’s Norris, who finished sixth.

"The data is fundamental in all of this – in our efforts to improve efficiency, in our efforts to bring new developments to the car faster," Rodriguez says.

The floor upgrade increased downforce, enabling the car to "stick to the track in the corners," Rodriguez says. "The faster you can go in the corners, the faster you can go during the race."

And in the world of Formula 1, fast is everything.

Author - Bill Briggs