WHAT DOES MULTI-ACCESS EDGE COMPUTING MEAN FOR MANUFACTURING?

The 5 advantages of using MEC with 5G and Wi-Fi

David LeBlanc, Director of Industry Solutions at AT&T Business, offers decades of experience in manufacturing and operations, including aerospace and automotive engineering. He routinely meets with manufacturers to discuss the pain points of their businesses and helps them discover the best solutions to meet their short- and long-term goals.

Q: There are more technology options for the manufacturing industry than ever. And while we know that the use of Internet of Things technology (IoT) continues to expand, so does the use of new and emerging near-real-time enabling technologies such as machine learning, robotics, artificial intelligence (AI), and augmented or virtual reality (AR/VR). How do you see this technology influencing the way manufacturers operate?

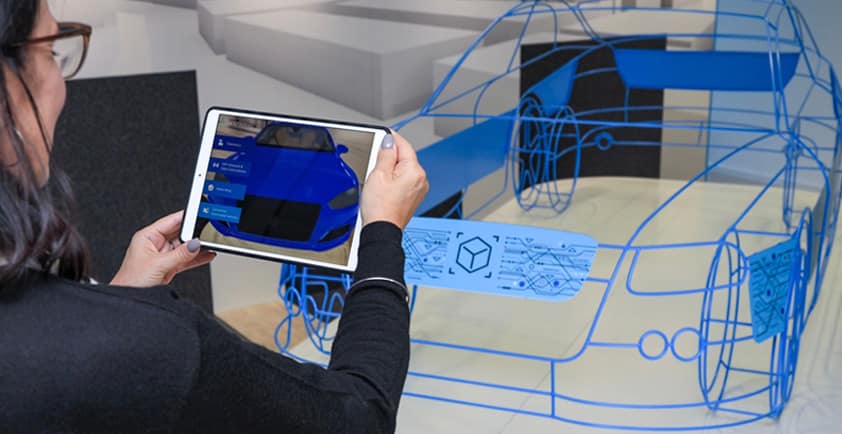

A: Manufacturers are changing themselves to achieve greater operational efficiencies using robotics, automation, computers, and low-cost sensors with analytics. For manufacturing companies, efficient production is a major element of operational efficiency. This includes optimizing equipment, product processes, and employee output, so they can produce the greatest number of quality products possible with the time and money invested. For instance, vision systems can enable inspections and quality control to be performed faster with fewer errors. Use of robotics allows for repetitive work to be shifted away from humans, leading to increased safety of workers. There is a shortage of skilled workers, so manufacturers can leverage augmented reality (AR) for training and remote assistance of less experienced workers on the plant floor. AR can also be used for "virtual commissioning" of new plants and equipment which results in savings in travel costs and efficient use of workers’ time. So manufacturing is looking for solutions that enable all this with lower latency, greater reliability, and better transport.

Q: That’s a lot of change. These technologies either generate or process large amounts of data. How can a network carry such a load of information?

A: Historically, this large amount of data has been transported within plants using wired or landline networks. However, the costs of laying out a wired network can be significant. Also, wired networks require that plant machinery must be fixed, since the wiring is not movable. Consequently, production lines cannot support flexible manufacturing, which leads to lack of agility to meet changing market needs. Consequently, many manufacturers have moved towards the use of Wi-Fi for selective applications, but this approach is also having issues. We are finding out that emerging technologies, as explained above, generally get ineffective results when using Wi-Fi due to bandwidth and coverage constraints, lack of stability, non-uniform coverage in-between access points (APs), and network saturation due to the large numbers of devices connected. More recently, the use of in-plant cellular networks (initially 4G/LTE and subsequently 5G using millimeter wave) have provided improved network transport of large loads of information. Finally, Multi-access Edge Compute (MEC) allows more processing at the edge so less transport of data to the customer cloud is necessary.

Q: There are other parts of the equation as well, correct? In addition to having the right network in place to suit a business, MEC can play a vital role in helping manufacturers reduce the latency of important data applications and prioritize mission-critical data. Could you share how you’re seeing MEC being used in this way?

A: Yes, that is correct! Many new and emerging applications in manufacturing require the availability of low-latency response of computations for their operations. Can you imagine a robot or a drone waiting for instructions from its application software to take its next step? An application that performs computing in a centralized cloud may result in a round trip time of 60-100 milliseconds, which is fine for phone calls, but may also be long enough to crash the robot or the drone. These applications are business-critical for the success of their end use, which are near-real time in nature. With the advent of MEC, the computing resource is moved from a central cloud and now brought closer to the where the usage is, which we refer to as the Edge. More appropriately, the computing is done on the premises of the manufacturing plant, potentially resulting in latencies of less than 10 ms. The eventual goal with MEC and 5G is to reduce this latency down to a single digit.

Other technologies, such as vision systems and large numbers of IoT sensors, also require the transport of high bandwidth data. Having a local computing resource, such as with MEC, makes it possible to contain the data inside the plant. This avoids the use of more expensive network transport to access a central cloud for computing. Another advantage is that a localized MEC will also increase the network reliability due to shorter distance and controlled environmental conditions, which is crucial for the use in automation and vision systems.

Q: Accessing the data is becoming easier for not just business leaders but also for operators on the factory floor through mobile devices such as IoT sensors and tablets. Why is MEC important for this?

A: Factory operators need business critical applications and services to make real time decisions and they need to be mobile – both inside and outside the plant. With the use of MEC, business -critical and other applications and services that require low-latency, high-reliability, increased privacy and security, or more effective transport can be located at the factory floor. Application computing can be done locally, as explained previously. With a localized cellular network in the plant area, any cellular-enabled devices that can connect with the network can be designated to get computed data from the MEC. Without the MEC, computations would be done in the central cloud, and the round-trip time latency would make the use of mobile devices in these circumstances somewhat challenging for near-real-time decision making on the plant floor.

Q: Accessing the data on mobile devices can possibly increase the cyber threat exposure, though. Is that correct?

A: Yes, that is correct. In general, the greater the number of end-points there are on a network, such as may be the case with IoT mobile devices, the greater the potential cyber threat exposure. The good news is that each mobile device has a unique identifier in its SIM card and its IMEI number. These identifiers can be used to control access to the network by authorized devices only. This security approach is extended to the MEC, and the MEC-enabled devices attached to it, because we architected the MEC to be an extension of the AT&T network. Additionally, to the extent the network is 5G, it will have been designed from the start with security in mind. This all helps to protect against potential cyber threats.

Q: Flexibility through mobility is important, because manufacturers are having to become more agile in response to the supply chain. It’s great that there’s a higher level of security through MEC because data is kept close. Retailers are collecting data from their shoppers to provide more customized experiences, which is also affecting how they order from manufacturers – the size of the orders, frequency of orders, and so on. The result is more of an on-demand manufacturing model, which has an influence on production cycles. How can MEC help in this new environment?

A: Apart from use with 5G, there are two factors that affect the enabling of stronger security through mobile devices for use with a MEC. First, as explained above, a list of allowed SIM cards can be authorized for connectivity to the AT&T core through the Distributed Antennae System (DAS). This DAS provides the localized network on the plant floor, and authorized SIMs are used to connect to the localized cellular network via the DAS. Therefore, prohibited or rogue units do not have access. Second, the MEC can have a built-in routing function which only sends information (in the form of IP packets) to allowed cellular destination IP addresses. Any IP address not in the routing table, therefore, cannot receive or send information. These two aspects provide a stronger degree of security for mobile devices connecting to a MEC.

Q: So it provides not only flexibility, but agility as well, then. Let’s dig into the technology a little bit more. What does a typical MEC architecture look like?

A: A MEC implementation requires a three-step process. First, a DAS is needed to provide a localized Radio Access Network (RAN) in a plant. DAS receives a small amount of traffic for control and signaling purposes of the Control Plane from the evolved packet core (ePC), which is AT&T’s macro cellular network. Fundamentally, the DAS is a small cell tower and converts RF waveforms from cellular networks into IP packets which are connected to an SIAD router. IP packet traffic flows from the DAS baseband unit via the SIAD to the MEC.

Second, the MEC is the "local" traffic aggregation point as all traffic from the RAN in the plant terminates there. Currently, the MEC is an X86 server. User Plane data is the application data that is used by emerging technologies and mission critical applications in the plant. The MEC is the "breakaway" point for traffic to remain in the plant or for going to the central cloud for storage or computing, based on the routing table concept discussed previously. The MEC can either perform the computing itself, or if its resources are exceeded, it can be connected to a data center on premises, with additional computing servers.

Third, the MEC or a local data center in the plant can be connected to the customer’s central cloud via MPLS network for sending and receiving data computed in the customer’s central cloud. This path could be used for sending long-term data for storage in the customer’s central cloud.

Q: That’s great information. We know that many manufacturing operations are small, and often companies are struggling not only to have enough workers, but the right workers with the skills to do specialized jobs. Does MEC require specialized skills to implement and maintain? If so, how can a business solve for this?

A: No. We have designed a simple interface for the customer. And to help our manufacturing customers who either do not have resources or the know-how to implement and manage a MEC, AT&T offers MEC as an AT&T-managed service. AT&T operates under a contracted agreement and is responsible to deliver the service. The cost of this service is a monthly recurring charge and affects the customer’s OpEx budget. A separate non-recurring installation and startup charge is also required. This MEC service is offered on a 36-month minimum payment period contract.

Q: Some of the benefits for MEC are similar to what 5G will provide. How would you describe the intersection between Wi-Fi, MEC, and 5G?

A: As the acronym MEC signifies, it’s a "multi-access" edge platform and currently allows for cellular access, and in the future will provide Wi-Fi access and other future data access types to the MEC. Both 5G and Wi-Fi devices can connect to the MEC via the architecture described previously. However, Wi-Fi is a LAN technology whereas 5G represents the promise of a wireless WAN future. Using cellular-based broadband as wireless WAN has been an essential part of enterprise networking for years. MEC is an on-premise edge solution. On a plant floor, MEC enhances capabilities of both from the standpoint of latency, high reliability, and massive device connectivity. There are five advantages in using the MEC in conjunction with either or both 5G and Wi-Fi when available:

1. Ultra-low latency – MEC is expected to improve latency with 4G/LTE today for 5G comparable latencies. 5G with MEC will offer ultra-low latency performance, beyond what 5G will offer by itself to a central cloud via the ePC

2. Higher reliability than 5G to central cloud, since the distance travelled to the MEC is shorter

3. Efficient transport to the central cloud for computing

4. Since computing is done on premise, we expect there will be greater degrees of cybersecurity and privacy protection

5. Authorization can be controlled for specific mobile devices when Wi-Fi is available

Q: So it’s not either/or, but "and," correct?

A: Yes, that is correct! The beauty of the MEC architecture is that both W-Fi and 4G within a plant can connect to it to achieve the benefits listed above. And MEC is flexible to include 5G to support customer’s future needs.

Q: Are there any other thoughts you’d like to leave us with?

A: We don’t have to wait until 5G nationwide coverage becomes available to implement MEC. 4G/LTE can be used today to allow customers to benefit now from the MEC advantages. Manufacturers should not wait for 5G, but rather let their use cases define what access technologies to use with the MEC. We encourage our valued customers to connect with the respective AT&T account teams for further assistance. We’re here to help!