ZF GLOBAL TECHNOLOGY DAY

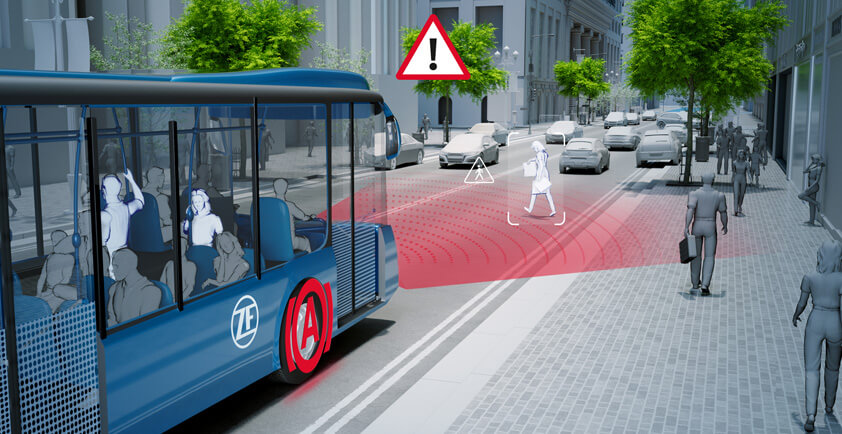

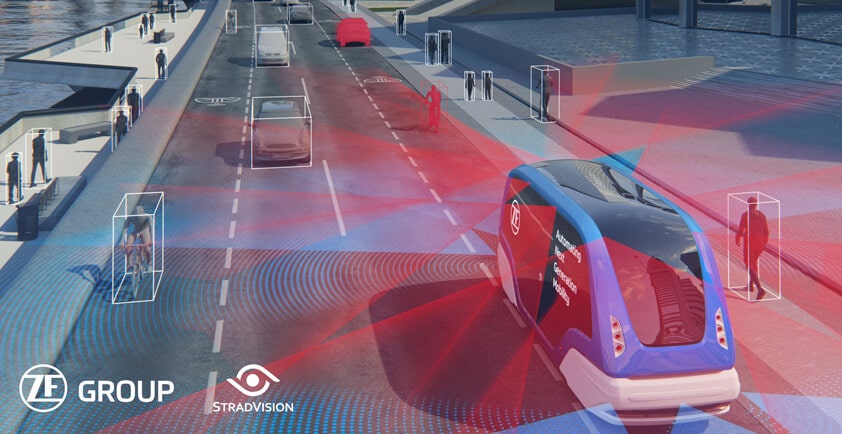

The rise of e-drives, connected and automated vehicle systems and software is part of a profound change in everyday mobility. ZF is actively shaping the transformation to clean, safe, comfortable, and affordable mobility of the future - for everyone, everywhere. At Global Technology Day, ZF will present current solutions from the passenger car, commercial vehicle, and industrial segments.

ZF TO SPEED UP TRANSFORMATION TO ELECTROMOBILITY AND NETWORKED CHASSIS TECHNOLOGY

Friedrichshafen. Technology company ZF unveiled its self-developed thermal management system for electric vehicles at its annual Global Technology Day demonstration event. The new system not only offers a more compact design of the drive but can also increase the range of vehicles in winter by up to one third. In combination with an optimized electric drive train consisting of power electronics, motor and reduction gearbox based on 800-volt silicon carbide, the system sets new standards in compactness and weight. The newly developed powertrain software also makes a significant contribution to higher efficiency.

"With this innovative solution, ZF is underlining its system expertise in electromobility and providing e-cars with a greater range," said Dr. Holger Klein, CEO of ZF. The new powertrain is free of heavy rare earth elements and can be used flexibly by car manufacturers thanks to its modular design. After presenting the concept last November, ZF has now realized the new generation of the electric drive with thermal management in a demonstration vehicle, which the company presented to journalists from all over the world at its headquarters in Friedrichshafen.

In the vehicle, the components of the electric driveline have been optimized and combined into a holistic system. The drive package has a 30 percent lower overall weight and, in this way, together with thermal management, enables a torque density of 70 Newton meters per kilogram of drive weight. This is a peak value for road-legal passenger cars currently available on the market. "Just a few months ago it was only a vision, now our drive can be experienced in a sports car," said Klein. "Not only are we consistently pursuing our strategy of sustainable and efficient mobility for the future, but we are also adapting our development processes to the new speed of our industry."

In view of the increasing speed and dynamic environment of change taking place in the automotive industry, ZF has also been optimizing its organization for several months: decision-making paths will be shortened, and processes made more agile to help the company be more responsive. ZF's global orientation is already proving its worth: one example is the all-electric Steer-by-Wire steering system, for which ZF has received customer orders from all major world markets. The cubiX chassis software or the first-generation 800-volt electric drive will also be used by automotive manufacturers from Asia, Europe, and America in their vehicles in the coming months.

ZF unites chassis technology to form the Chassis Solutions Division

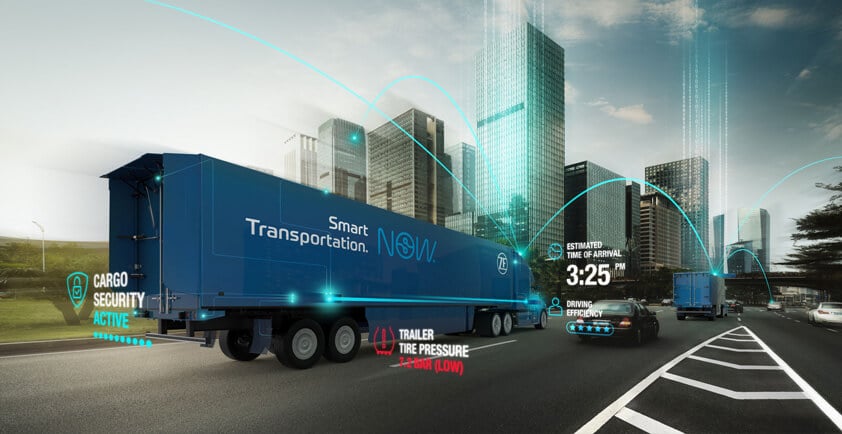

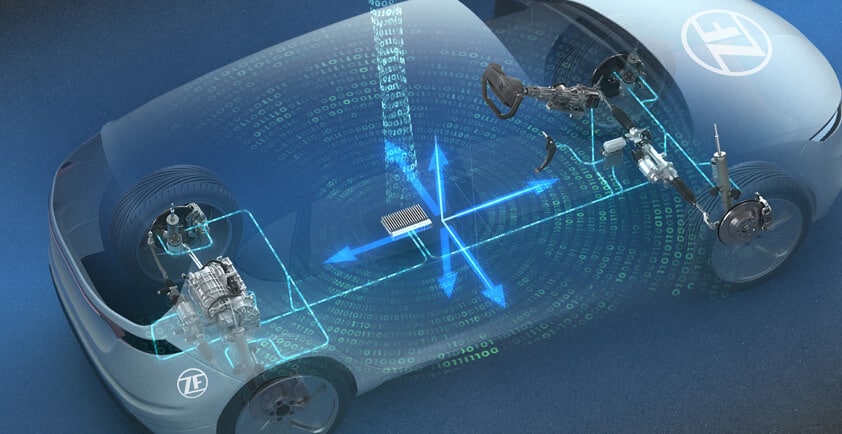

In addition to electromobility, ZF’s by-wire products as networked and electronically controllable braking, steering and damping systems are examples of additional future business in the volume segment: chassis technologies. With its experience and know-how, ZF masters the longitudinal, lateral, and vertical control of a vehicle and sees great potential for the future in networked chassis components. Against this background, ZF is merging the divisions for passenger car chassis technology and active safety technology to form a new and uniquely comprehensive Chassis Solutions division.

The new unit bundles ZF’s entire chassis, steering and braking expertise. "The Chassis Solution division offers all the hardware components needed to control a vehicle’s vertical, longitudinal and lateral dynamics – and also the associated networking in the form of hardware and software," explained Klein. "The unit already combines an annual turnover of more than 14 billion euros and will be a reliable and competent partner for our customers in all regions of the world." The launch of the new division is planned for January 2024. In the future, all mobility segments will benefit from the developments and know-how of this new ZF division – the commercial vehicle sector as well as industrial applications.

Customer demand shows that ZF is on the right track with its "Next Generation Mobility" strategy. The technology group's goal is to use technology to make the mobility of the future clean, safe, comfortable, and affordable – for everyone, everywhere.

WORLD CHAMPION IN TORQUE DENSITY: ZF PRESENTS MOST COMPACT E-DRIVE FOR PASSENGER CARS

Friedrichshafen. At its Global Technology Day in Friedrichshafen, ZF is presenting the electric concept vehicle EVbeat, which is designed for maximum compactness, low weight, and maximum efficiency in real operation. In this ZF electric vehicle, the components of an e-driveline have been optimized and combined into a holistic system. These include the 74-kilogram lightweight and ultra-compact driveline with a torque density of 70 Nm/kg, holistic thermal management and cloud-networked driveline software. At cold temperatures around freezing point, the range in real-world operation increases by up to a third compared with current technology.

"Sustainable mobility is at the core of our corporate strategy," explained Stephan von Schuckmann, member of the ZF Board of Management responsible for electrified driveline systems, among other things. "Based on an extremely efficient production vehicle, we are showing the potential that future electric drive components offer when we combine them into an even more efficient overall system."

The ZF EVbeat concept vehicle is based on a Porsche Taycan and takes leading series technology from ZF and other market players as a benchmark.

"Our goal was to make this drive as compact and lightweight as possible while maintaining high driving dynamics and increasing efficiency in real-world operation," said Dr. Otmar Scharrer, Head of Development for Electric Driveline Systems at ZF. "In terms of torque density, we are at the top of the podium when we compare ourselves with e-drives for passenger cars currently available on the market. At the same time, we paid strong attention to the sustainability aspect during development." The electric motor works without heavy rare earths and the thermal management system does not use fluorine-based coolant. The reduced number of components and the overall 30 percent reduction in system weight for the electric drive and thermal management system make a double contribution to greater sustainability - both in production and operation.

EVSys800: ultra-compact and lightweight 800-volt drive

The EVSys800 is a modular 800-volt drive and consists of silicon carbide power electronics, the electric motor and a reduction gearbox. Despite its extremely compact design and light weight, the EVbeat does not skimp on performance: The concept vehicle has a maximum torque of 5200 Newton meters available on the rear axle – and this with a uniquely high torque density for road-legal passenger cars with of 70 Newton meters per kilogram. The continuous and peak power of the electric motor is 206 and 275 kilowatts, respectively – ZF thus achieves continuous power of around 75 percent of the peak power.

In terms of dimensions, the drive saves 50 millimeters in width thanks to the compact reduction gearbox and the ZF-patented ‘Braided Winding’ technology of the electric motor, thus enabling space-saving, coaxial installation on the drive axle.

With a total weight of 74 kilograms, the EVSys800, normalized to the same output as the latest ZF 800-volt series drive, is about 40 kilograms or 30 percent lighter and thus contributes significantly to the weight savings of the concept vehicle.

Essential for this is the electric motor with a new cooling concept and a new winding technology. For cooling, ZF allows oil to flow directly around the copper rods – exactly at the point where most heat is generated during operation. Such highly efficient cooling significantly increases performance with the same weight and installation space. In addition, the use of heavy rare earths can be dispensed with, and the electric motor can be produced more sustainably. The ‘Braided Winding’ technology developed and patented by ZF, is a further development of the so-called wave winding and enables a total of ten percent less installation space. The winding head alone is up to 50 percent smaller than with conventional approaches. This saves around ten percent copper.

The inverter of the electric drive has been fundamentally redesigned. All essential components have been fundamentally revised. Significant improvements were achieved in each of the areas of electromagnetic compatibility, power modules and capacitors in terms of installation space, weight and sustainability.

A new, coaxial reduction gearbox transmits the drive forces of the electric motor via two planetary gear sets. They not only generate the desired final drive ratio, but also perform the fully integrated differential function. Compared with conventional offset concepts, in which the input and output shafts are not on the same axis, the coaxial solution reduces weight and installation space requirements without compromising on efficiency, noise and vibration. In combination with ‘Braided Winding’ technology, this drive can be made significantly shorter, allowing installation in almost any vehicle installation space.

"With this system, we can perfectly meet the main requirements of our customers – namely efficiency, performance and costs," said Dr. Otmar Scharrer. The first technologies of the new ZF driveline will be available on the market from 2026.

Thermal management: Efficient temperature control of the powertrain and the entire vehicle

The temperature control of a vehicle can account for a significant proportion of its energy requirements in winter, which can be between three and six kilowatts, especially when heating up. Pleasant coolness in summer and warmth in winter are major comfort factors for the occupants. The right temperature is also an essential factor for the performance of the electric motor, the power electronics and the battery.

The first central thermal management system (TherMaS) developed by ZF for electric vehicles is integrated into the EVbeat concept vehicle. TherMaS uses a central unit and intelligent software to control all thermal processes for the driveline and passenger compartment. The new design significantly reduces space requirements and weight compared to previous approaches for cooling and heating e-cars. A propane-based 800-volt heat pump also requires significantly less energy. Because it is compact and simple in design, it can be easily integrated into vehicles.

The TherMaS concept has three designated circuits for the first time: At the center is the very small refrigerant circuit. This is pre-filled and hermetically sealed and is therefore maintenance-free. In addition, the concept has no interfaces to other vehicle areas such as the interior. ZF uses the fluorine-free, natural refrigerant propane. Although only half the previous refrigerant is used, the cooling capacity increases by a factor of two compared with refrigerants commonly used today. If required, the central refrigerant circuit serves two separately controllable cooling circuits in which frost-protected water flows as usual: The first is designed for the comparatively high temperatures of the electric motor, while the second regulates the temperature of the power and charging electronics. The control software regulates the cooling capacity.

Thanks to this overall thermal management, the range of the EVbeat increases by up to a third in demanding winter operation. The significantly better cooling performance makes the higher continuous output of the e-machine possible.

Powertrain software: efficiently network vehicle drive and cloud

The properties of the hardware systems lay an important foundation for the sustainable operation of the vehicle; their optimum orchestration is achieved via the software. ZF has developed its own powertrain software that networks all vehicle systems with each other and establishes the connection to the ZF cloud.

Because the efficiency of an electric motor depends on its thermal operating points, it is important to keep them in the optimum range at all times: At low speeds and high torque requirements, the optimum thermal operating point is very low, while at high speeds with low torque requirements, high temperatures are not a problem. However, the thermal conditions cannot be established at short notice. ZF’s driveline software can anticipate the optimum operating points from the individual driving profiles and prepare the system accordingly. It "learns" the behavior of drivers and can anticipate the probability of individual driving profiles through an AI-based cloud service. For example, air conditioning and system cooling are reduced when short distances are detected.

On this basis, the assistance system can also give drivers direct advice on how to use the electric vehicle efficiently. For example, efficient acceleration and deceleration as well as an optimized maximum speed are displayed. This is particularly valuable when it comes to calculating an accurate and practical range before the journey, which is then reliably adhered to.