CONTINENTAL PRESENTS HIGH-PERFORMANCE PLATFORM FOR THE VEHICLE COCKPIT OF TOMORROW

>> Integrated Interior Platform: outstanding user experience of connected and automated mobility of the future for driver and passenger

>> Milestone in E/E architecture: the platform provides the computing power for all applications and services in the cockpit

>> Despite complex requirements, Continental’s Software Factory ensures quality, speed and efficiency in development

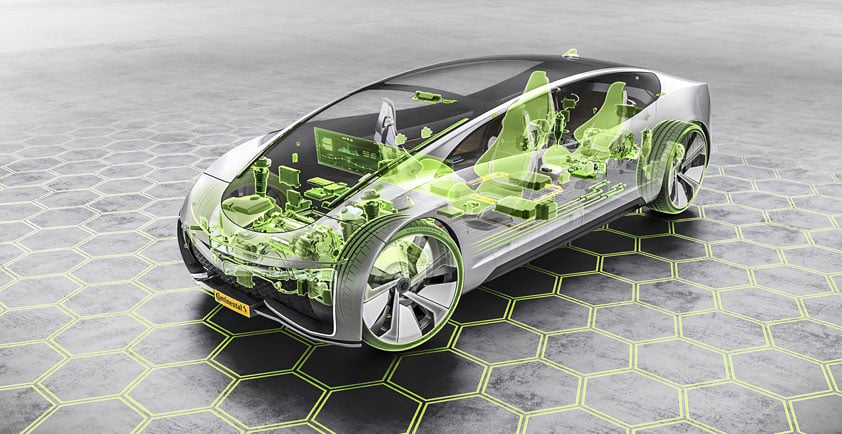

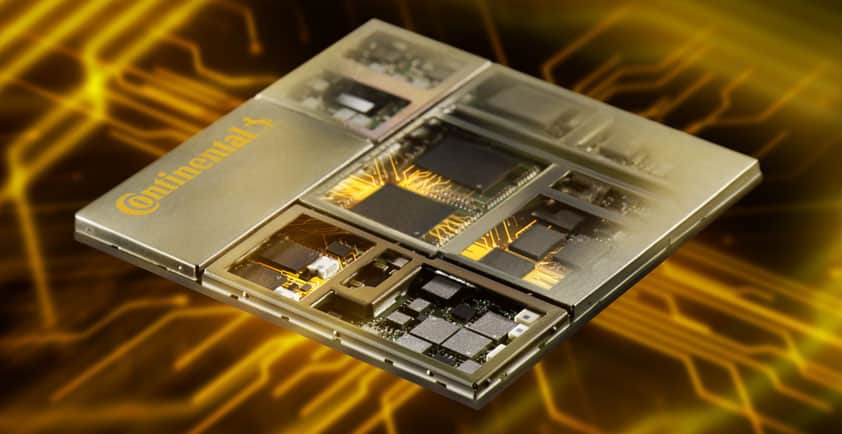

Wetzlar/Frankfurt Continental presents the latest version of its Integrated Interior Platform (IIP). As a high-performance computer, this comprehensive solution for software and hardware provides the basis for interaction between humans and vehicles in the connected cockpit of tomorrow – and at the highest level of quality. In its cockpit demonstrator, the technology company will show how the IIP combines various displays, such as the instrument cluster and the center console display, with Internet-based services to form a complete solution. The IIP is a milestone in the E/E architecture revolution, which is seeing in-car electronics move away from many individual control units to a few high-performance computers.

Continental uses virtualization solutions for the IIP architecture that allow several operating systems with various security requirements to be operated simultaneously on a single computer. The operating systems, such as QNX, Integrity, Linux and Android Automotive, can come from both open-source and third-party providers. The required software is integrated and tested in the highly automated and agile Continental Software Factory. From its Agile Campus at the company’s Wetzlar location, Continental has also shortened development cycles by fundamentally changing processes and ensuring effective collaboration.

“The cockpit of tomorrow poses two major challenges for our development. Firstly, there is an ever-increasing separation of software and hardware, along with the numerous possibilities for various open-source software and thus also for new business models. Secondly, to implement processes that allow us to meet these new requirements rapidly, efficiently and with a high level of operational security proves to be challenging as well,” explains Dr. Karsten Michels, head of Systems & Technology in Continental’s Interior division.

The IIP supports a wide range of products and is scalable using various hardware concepts. “To tackle the challenges of system integration, we are changing the culture at Continental to focus on agile working. We have accelerated this change with our Agile Campus at the Wetzlar location. This includes a high level of automation of continuous test routines and a combination of strict gating and transparent quality metrics. The focus of our development is on quality,” says Michels.

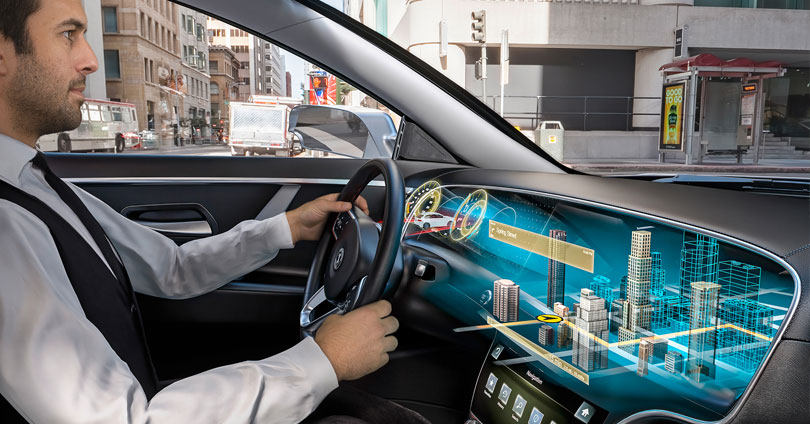

In the automated driving mode, the displays go to full size. The IIP now allows passengers to fully immerse in their digital office or entertainment environment.

Integrated Interior Platform: technology for the cockpit of tomorrow

The IIP features displays connected across the entire width of the cockpit under a glass surface, highlighting the number of functions that fully connected vehicles must be able to master at the same time. The digital driver display, for example, will show the view of the digital rear-view mirror in addition to traditional readouts. Moreover, the driver can use gestures to retrieve content such as high-resolution navigation maps from the passenger display. If the driver then switches to automated driving mode, the full display is shown, featuring all Internet-based services and apps that are otherwise only available on the passenger side. The IIP is capable of controlling multiple displays in the cockpit. To do so, the platform must be able to run both apps with a high automotive safety integrity level and those that are as open as possible (e.g. based on Android) from a wide variety of sources. The secure encapsulation of various operating systems through hypervisor technology or containers is therefore an integral part of the IIP. During manual driving, the passenger has the entire spectrum of familiar digital services available, including common office applications.

CONTINENTAL AND LEIA´S NEW 3D LIGHTFIELD DISPLAY BRING THE THIRD DIMENSION INTO AUTOMOTIVE VEHICLES

>> Innovative Lightfield technology generates an unprecedented 3D experience for all vehicle passengers without special eyewear

>> Comprehensive display technology and content platform for increased safety and comfort demands within the vehicle

>> Continental works together with Silicon Valley company Leia Inc.

Babenhausen (Germany). A stop-sign, shining red hovers in front of the screen. Rows of houses rise out of the navigation system. The vehicle manufacturer’s logo rotates in the air in front of the dashboard. With these kinds of three-dimensional effects, Continental aims to revolutionize the way displays are configured in automotive vehicles. The technology company is currently developing an innovative cockpit solution, the Natural 3D Lightfield Instrument Cluster, in cooperation with Silicon Valley company Leia Inc. that will bring the third dimension into upcoming automotive vehicles, with unprecedented quality. Lightfield displays are the next generation of medium allowing not only the comfortable perception of 3D depth, but also the rendering of highlights, sparkles and other complex light effects. The technology enables information to be safely presented to the driver in real-time, allowing the driver´s interaction with the vehicle to become more comfortable and intuitive. It also allows passengers in the front and back seats to share the 3D experience with the driver.

“A new dimension of comfort and safety”

The new Lightfield cockpit is an evolutionary step in the design of the human-machine interaction within automotive vehicles. “One of today’s greatest challenges in the automotive industry is to develop intelligent concepts for the human-machine interaction. To create solutions that enhance the driver experience and allow the driver to simply and effectively interact with the vehicle without becoming distracted from the road”, explains Dr. Frank Rabe, head of business unit Instrumentation & Driver HMI at Continental. “The new Lightfield display does not just bring the third dimension of the highest quality into the vehicle - the innovative technology also creates a new dimension of comfort and safety. In addition, our solution provides every vehicle manufacturer the possibility to enhance the driver experience for their customers and to differentiate themselves from competitors thanks to customized scopes for design.” The new system is said to go into series production by 2022.

On the way to automated driving, there will be more opportunities for the driver to engage in other activities such as video calling, internet browsing or watching shows and movies. “The car is clearly the next frontier for Mobile” says David Fattal, Leia Inc. co-founder and CEO. “To us it’s a bigger, more immersive version of a smartphone with full 3D awareness of its environment. It’s a logical place to deploy our growing Lightfield ecosystem of immersive gaming, video streaming, social sharing, or even e-commerce.”

Visualizing content on a wide display specially designed for in-car visual comfort will be much more refined and enjoyable than using one´s smartphone. It will also offer the opportunity to leverage internal or external camera systems for video calling or augmented reality functions, a feature that the partnership intends to exploit.

3D Lightfield content can be seen by everyone in the vehicle

Leia´s Lightfield technology used for Continental’s natural 3D display does not need a head-tracker camera – a practical and, of course, cost-efficient advantage. Moreover, passengers in the front and back seats can also clearly see the same 3D image from their seated positions – something that was previously not possible. Furthermore, there is yet another leap in quality of the new system in comparison with previous 3D-methods. The 3D-image produced by the Lightfield display is made up of a total of eight perspectives of the same object that subtly vary according to the point-of-view.

A glance at the Lightfield display "wanders" when changing the angle from every passenger position – in this way an exceptional and unique natural display of information is possible. “Thanks to our Lightfield display, we achieve a completely new level of 3D-image display”, says Kai Hohmann, Product Manager, Display Solutions at Continental. “The newly developed light conductor with nanostructures is essential for the quality. We are not refracting the light, we are bending and guiding it precisely to attain the optimal 3D-effect needed. Only via this technology it is possible to meet the ever-increasing requirements for comfort and safety within the interior of the vehicle.”

Continental is now adapting Leia’s technology for use in automotive vehicles. Until recently, either parallax barriers or lenticular techniques were used to achieve a glasses-free 3D effect. They achieve a 3D effect through a special method of blocking or refracting light. Parallax barrier systems, in particular, offer only a single user application by requiring a head tracker system to adjust the 3D views towards the observer´s exact head position. Furthermore, in a similar way to a filter, they can negatively impact the perceived image quality and effectiveness of the light output in a multi-user application designed for the driver, co-driver and rear passenger. For the automotive industry, the highest quality especially for displaying information is imperative. Continental’s new 3D Lightfield application comprising Leia’s DLB™ (Diffractive Lightfield Backlighting) technology offers the next level above conventional 3D displays and enables a crystal-clear screen, even when sunlight is shining directly onto it.

Use of nanotechnology from Silicon Valley

The quality of the resolution as well as the look and feel of the Natural 3D Lightfield Instrument Cluster is clearly higher than that of conventional 3D-displays. This has been achieved thanks to Diffractive Lightfield Backlighting, which is a newly developed technology, whereby light conductors with diffraction grating and nanostructures create a precise diffraction of light under the display panel – thus creating a natural 3D-effect. This light-field module can be easily integrated into commercially available displays.

“Leia has developed cutting-edge nano manufacturing process suitable for large scale and mass volume, which allowed the commercialization of its technology last year. We have bridged advanced lithography onto large-scale substrate with high yield and competitive cost, leveraging experience rooted from HP and continued in-house development over the past five years. Now we will bring this unique capability to even larger scale while complying with automotive safety standards and cost competitiveness”, says Zhen Peng, Leia Inc.’s co-founder and CTO. Leia’s Lightfield technology made its commercial debut in the U.S. through smartphone displays with AT&T and Verizon. Consumers are already able to enjoy gaming, movies, augmented reality and the sharing of pictures in unprecedented 3D quality. The Lightfield experience consists of the Lightfield display and a comprehensive amount of automotive use case applications which will be provided by Continental.