BITS AND BYTES IN BERLIN: HOW BOSCH IS CONNECTING CARS, KITCHENS, AND FACTORIES

>> Connected mobility: more enjoyment, safety, and efficiency for car drivers.

>> Connected manufacturing: greater flexibility and transparency in logistics.

Berlin/Stuttgart – The internet of things (IoT) is changing mobility fundamentally, making kitchens smart, and factories more productive. Bosch is showcasing these and other solutions at Bosch ConnectedWorld 2019 in Berlin, where the IoT sector meets to discuss tomorrow’s world. Innovative products and services are making everyday life not only more convenient, but also safer and more efficient – at home, at work, and on the move.

Move #LikeABosch: products and solutions for connected mobility

Software updates from the data cloud: Cars stay on the road for 15 years or more. To ensure vehicle software is kept up to date, more and more carmakers are implementing cloud-based software updates. As a result, the software of critical control units can be updated as easily as on a smartphone – without any time-consuming visits to a dealership. Bosch has developed all the features required for these wireless solutions in-house. They range from the control units and in-car communication infrastructure to modern encryption technologies and the Bosch IoT cloud. More than five million cars are already updated over the air with Bosch IoT suite software.

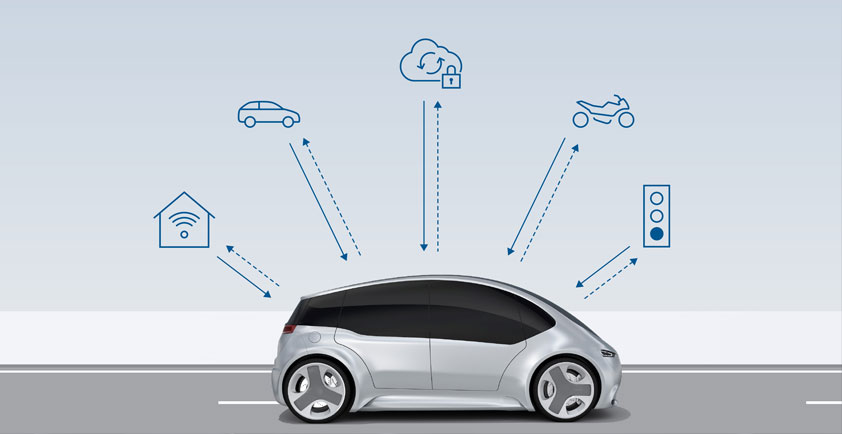

Connectivity control unit for V2X communication: For direct vehicle-to-everything (V2X) communication, Bosch has developed a smart connectivity unit capable of communicating using all transmission technologies based on Wi-Fi or mobile network-based communications. Equipped vehicles are able to communicate with one another as well as with their surroundings regardless of the vehicle make or the country in which they are used. Bosch is cooperating with the Portuguese startup Veniam to handle the complex task of managing the data connections. The software constantly searches for the best transmission technology for each requirement and switches automatically between the available options. It therefore maintains continuous and seamless vehicle connectivity, ensuring cars can reliably alert one another to accidents, the approaching tail end of a traffic jam, and icy conditions.

Holistic automotive security: Vulnerabilities in the IT security of connected and automated vehicles are by no means just limited to the vehicle itself. Attackers could potentially gain access to vehicle data or cryptographic keys during production. Or cyberattacks could use connected vehicles to target backend systems. Holistic automotive security must therefore combine manufacturing IT security, embedded IT security, and enterprise IT security. The provider of automotive security systems ESCRYPT, a wholly owned Bosch subsidiary, develops integrated security solutions across the entire automotive value chain – from car manufacturing to connected vehicles, and right through to connected backend systems and mobility services.

Rapid assistance with Vivatar drive: Vivatar is the digital guardian angel for people on the go. Whether on foot or in the car, it makes sure that help arrives quickly when called. To this end, Bosch has combined the Vivatar app with the new Vivatar Telematics plug. The retrofit eCall adapter simply plugs into the car’s cigarette lighter and connects with a smartphone app. Vivatar drive detects car accidents and in an emergency automatically calls for help using the Bosch emergency assistant – whether the car is driving along a remote road out in the country or through western Europe. Vivatar drive can thus also be retrofitted in car models that are not factory-equipped with an eCall emergency assistance system.

A great recharging experience: The integrated charging and navigation solution Convenience Charging from Bosch offers drivers of electric vehicles precise range forecasts, route planning that factors in any recharging stops needed, and easy charging and payment. With new geopositioning services, Bosch helps drivers make the most of the time spent recharging, actually making the stop something to look forward to. For instance, drivers can use the reservation platform integrated in the route planning software to book within seconds a table at a restaurant near the charging station. A unique feature, the system can suggest suitable eateries, bars, or cafés at new destinations based on the driver’s previously saved preferences. In addition, Bosch’s Convenience Charging also includes mobile charging services. This allows drivers to recharge their electric vehicle even if there is no charging facility nearby. To this end, Bosch has teamed up with third-party providers such as the Berlin startup Chargery. The full-service provider Chargery offers a mobile charging service that uses cargo bikes to take the power directly to where the car is.

Augmented reality with Microsoft HoloLens 2: Bosch uses augmented reality (AR) to train mechanics to handle complex repair jobs on vehicles, for example. Available AR training include a training for high-voltage vehicle system. One example is a training program for high-voltage vehicle systems. The visualization provided by AR gives participants detailed insights into the structure and functionality of the components. In partnership with Microsoft, Bosch is one of the first companies worldwide able to use the AR solutions it has developed in-house on the new HoloLens 2. The headset’s much bigger field of view gives repair shop workers access to more information at a glance and allows them to look at larger objects up close

Manufacture #LikeABosch: products and solutions for all aspects of connected manufacturing

Intralogistics in motion: Autonomous transport systems bring flexibility and transparency to intralogistics. Bosch Rexroth’s new ActiveShuttle moves loads weighing up to 260 kg quickly and safely through production facilities. An integrated hub platform enables fully automated loading and unloading of dollies equipped with small load carriers. As a result, ActiveShuttle can facilitate many kinds of transport concepts, ranging from cyclical deliveries to consumption-based material supply. Even when other transport vehicles are in play and people are present, the vehicle merges effortlessly into the intralogistics environment.

Visual inspection using artificial intelligence: Artificial intelligence holds huge potential to improve manufacturing quality and productivity. ViPAS from Bosch is an AI-based system for visual quality control. Equipped with a gripper arm, cutting-edge camera technology, and intelligent software, ViPAS inspects the most diverse kinds of components ranging from screws to pumps and right through to common-rail injectors. It compares the images recorded with stored information and classifies the parts either as “OK” or “not OK” (i.e. faulty). Thanks to deep learning, the system can be trained with sample images. As a result, ViPAS can be used for a range of visual inspection tasks.

3D printing for industrial applications: Bosch and BigRep, one of the leading suppliers of large-format 3D printers, are working on establishing 3D printing as industrial production technology. Automated additive manufacturing can not only be used to produce prototypes and models quickly and efficiently, the technology is also being readied for deployment in mass manufacturing. To this end, the companies have equipped BigRep printers with IoT solutions from Bosch. IoT devices, software, and intelligent sensors monitor all operating conditions and help to optimize process quality. This data also increases the quality of the printed components. The software is able to detect wear and errors before they cause machine downtime, thus increasing the availability of 3D printers.

Software for a transparent value stream: Nexeed software harmonizes, analyzes, and visualizes big data volumes in connected manufacturing. It can help to raise productivity by up to 25 percent at individual facilities or reduce stockpiling by as much as 30 percent as internal projects at Bosch have demonstrated. On top of that, Nexeed can increase flexibility within plants: machines can be retooled faster and geared up for customized production – all the way down to batch sizes of one. In intralogistics and extralogistics as well, Nexeed software improves the transparency of materials flows and international supply chains.

Intelligence for autonomous robots: Bosch’s mobile robotics platform is an innovative software solution for developing and operating autonomous mobile robots in industrial applications. Within a short period of time, robots can learn, for example, to get their bearings, detect and navigate around obstacles, or load and unload items such as pallets or boxes. Via the cloud, the operator can also see where a robot is located and what job it is performing and can assign new tasks to it. Based on a modular, generic platform, the approach allows different robots and whole fleets of robots to be individually and quickly equipped with this intelligence and operated. Potential areas of application include robotic cleaners that autonomously clean large facilities such as train stations or airports, logistics robots to transport items within large warehouses, for example, or outdoor machinery for agricultural or construction uses.

Bosch Elevator Cloud monitors elevators: In this solution, sensors record elevator operating data that is subsequently transferred to the cloud and analyzed. The evaluated information helps detect elevator breakdowns and predict future disruptions in operation, thereby increasing elevator availability and easing the job of elevator operators. The aim is to extend these smart services in future to include other systems such as heating or air-conditioning systems.